Well stimulation is a process used to increase well productivity by techniques like hydraulic fracturing, acidizing, and nitroshooting. Stimulation aims to enhance production in new or older wells in oil and gas reservoirs. Key methods are hydraulic fracturing which creates fractures, acidizing which involves using acid to remove damage and improve permeability near the wellbore, and nitroshooting which uses explosives. Success is evaluated by comparing productivity indexes before and after stimulation.

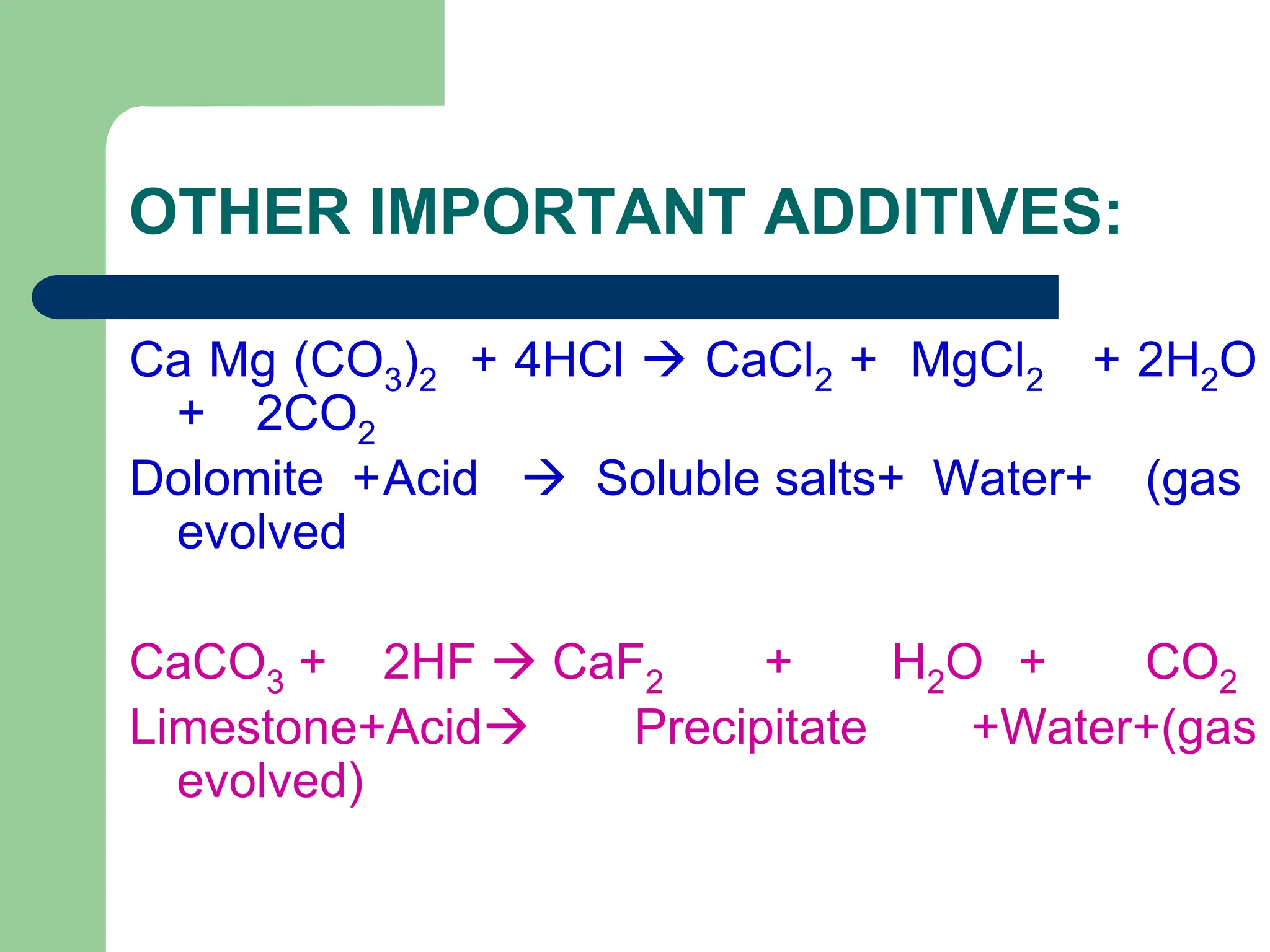

![INITIATION OF FRACTURES

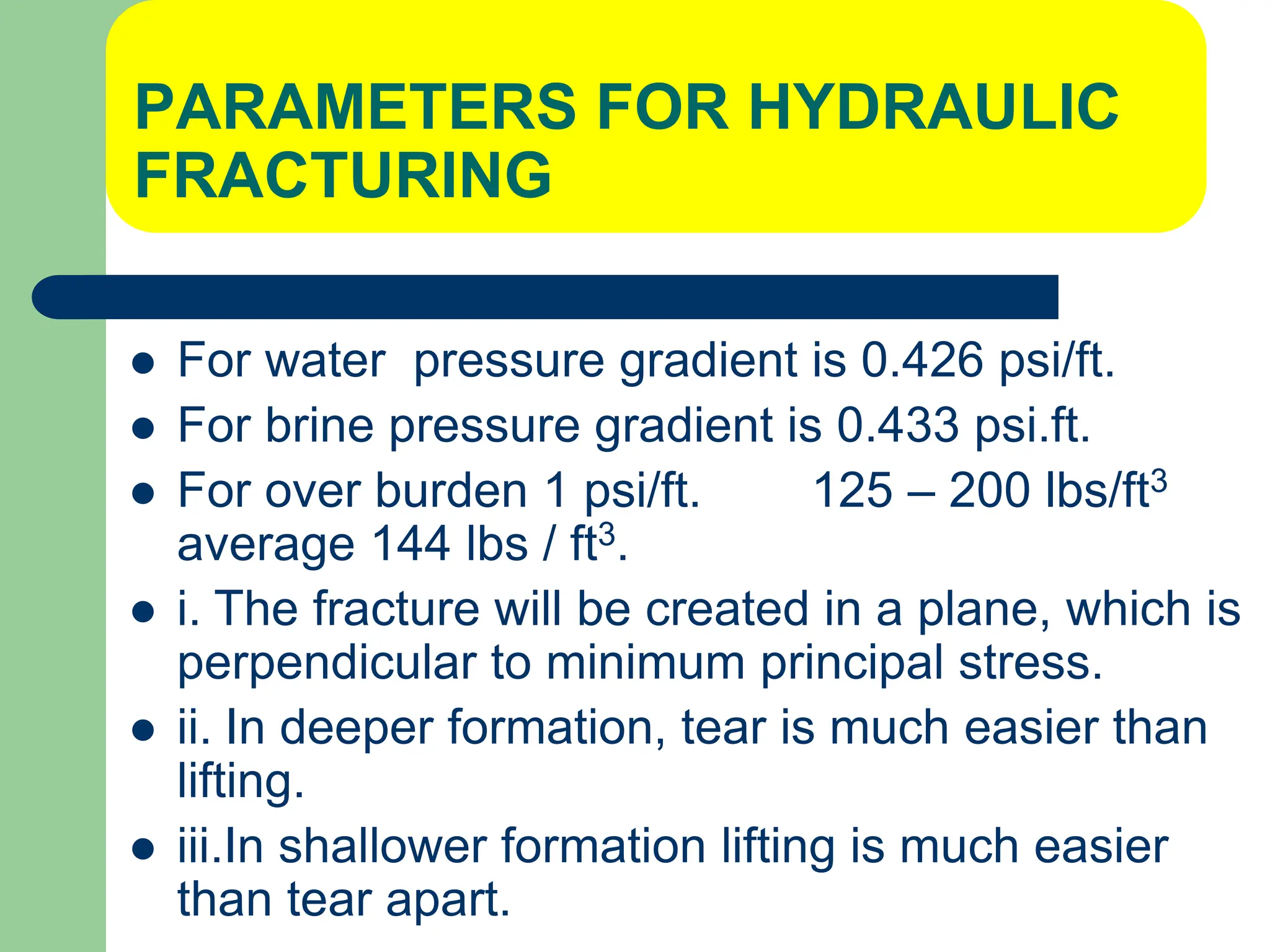

i. Pressure required to create a Horizontal

fracture

Pf (h) = Z = 1.0 x D

Where D is the depth in feet

ii. Pressure required to create a vertical fracture

Pf (v) = [ 2 / (1 - ) ] Z + St

Where is Poisson’s ratio = lateral strain / axial

strain varies between 0.18 to 0.27 for the

average type of rocks.

St = tensile stress.](https://image.slidesharecdn.com/208848123-well-stimulation-240414152512-51a7be1c/75/208848123-Well-Stimulation-techniques-ppt-5-2048.jpg)