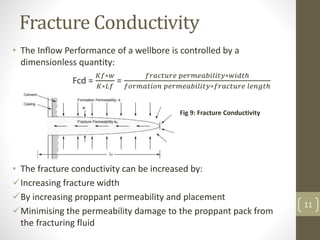

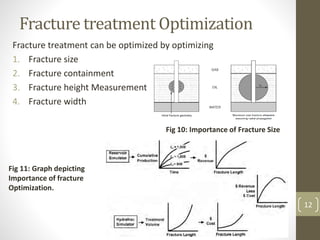

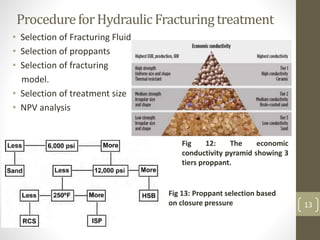

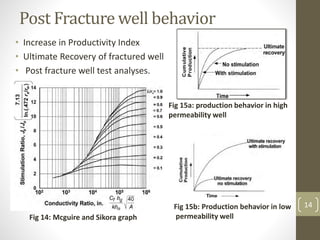

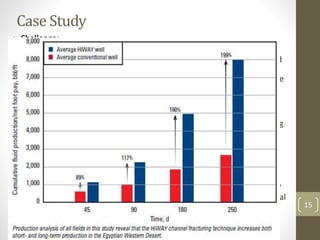

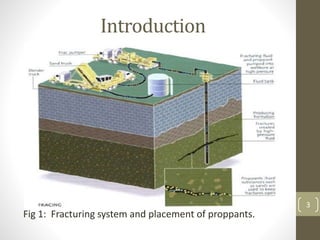

This document discusses hydraulic fracturing, which is a well stimulation technique used to increase production from low permeability reservoirs. It involves injecting fluid into the wellbore at high pressure to create fractures in the rock formation. Proppants, such as sand or ceramic beads, are placed in the fractures to keep them open after pressure is removed. Key aspects covered include fracture modeling, optimization of fracture size and conductivity, candidate well selection, and a case study showing production increases from hydraulic fracturing treatment.

![Hydraulic Fracturing

By

Shreyansh Shukla (67086)

[Guided By Prof S.J. NAIK] 1](https://image.slidesharecdn.com/hydraulicfracturing-161015143201/85/Hydraulic-fracturing-1-320.jpg)

![Fracture Mechanics

• The mechanics of fracture initiation and extension, and the

resulting fracture geometry are related to the stress condition

near the borehole and in the surrounding rock, the properties

of the rock, the characteristics of the fracturing fluid, and the

manner in which the fluid is injected.

• It is well known that in the subsurface there are 3 principle

stresses oriented at right angles to each other [Fig 6].

• The magnitude and direction of the principle stresses are

important because they control the pressure required to

create and propagate a fracture, the shape and vertical extent

of the fracture, the direction of the fracture, and the stresses

trying to crush and/or embed the propping agent during

production.

• Fracture propagates in the perpendicular direction of

minimum stress (due to least resistance).

Fig 6: In-Situ stresses

8](https://image.slidesharecdn.com/hydraulicfracturing-161015143201/85/Hydraulic-fracturing-8-320.jpg)