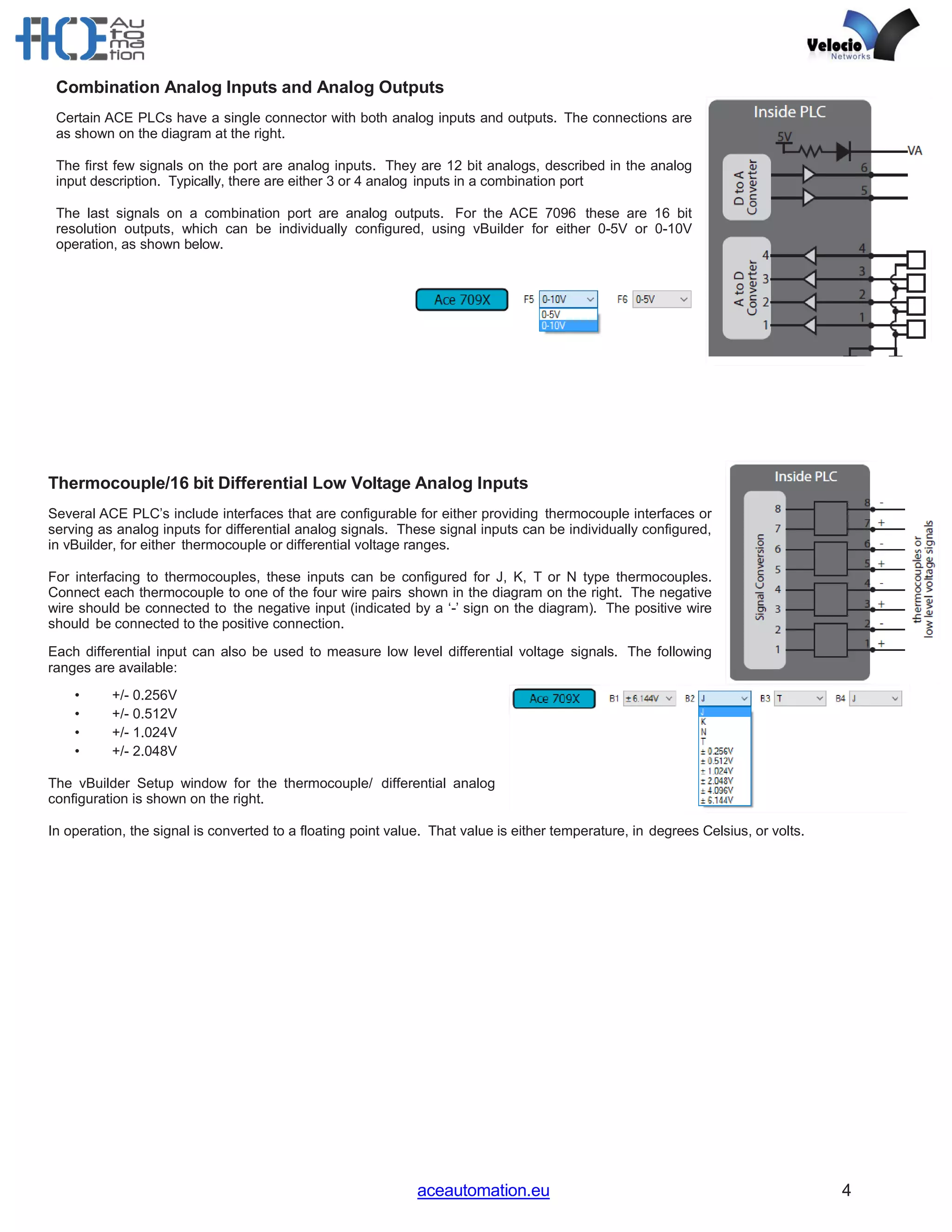

The document details the features and capabilities of Velocio's ACE programmable logic controllers (PLCs), emphasizing their compact size, advanced functionalities, and user-friendly programming through VBuilder software. ACE PLCs offer extensive input/output options, digital and analog interfaces, as well as support for motion control and communication protocols like RS232 and RS485. The document also covers aspects of installation, wiring, and mounting options for optimal use in various automation applications.