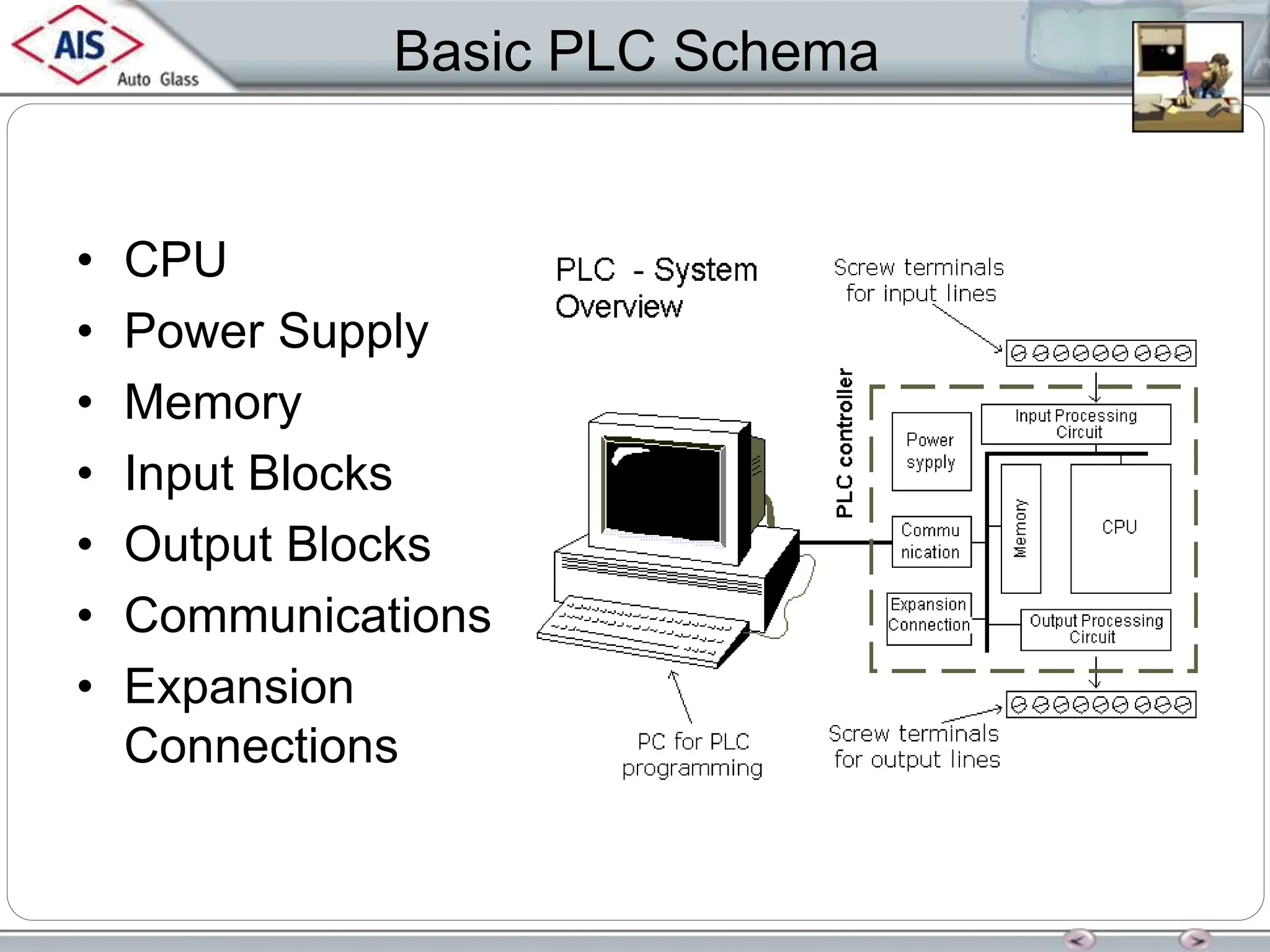

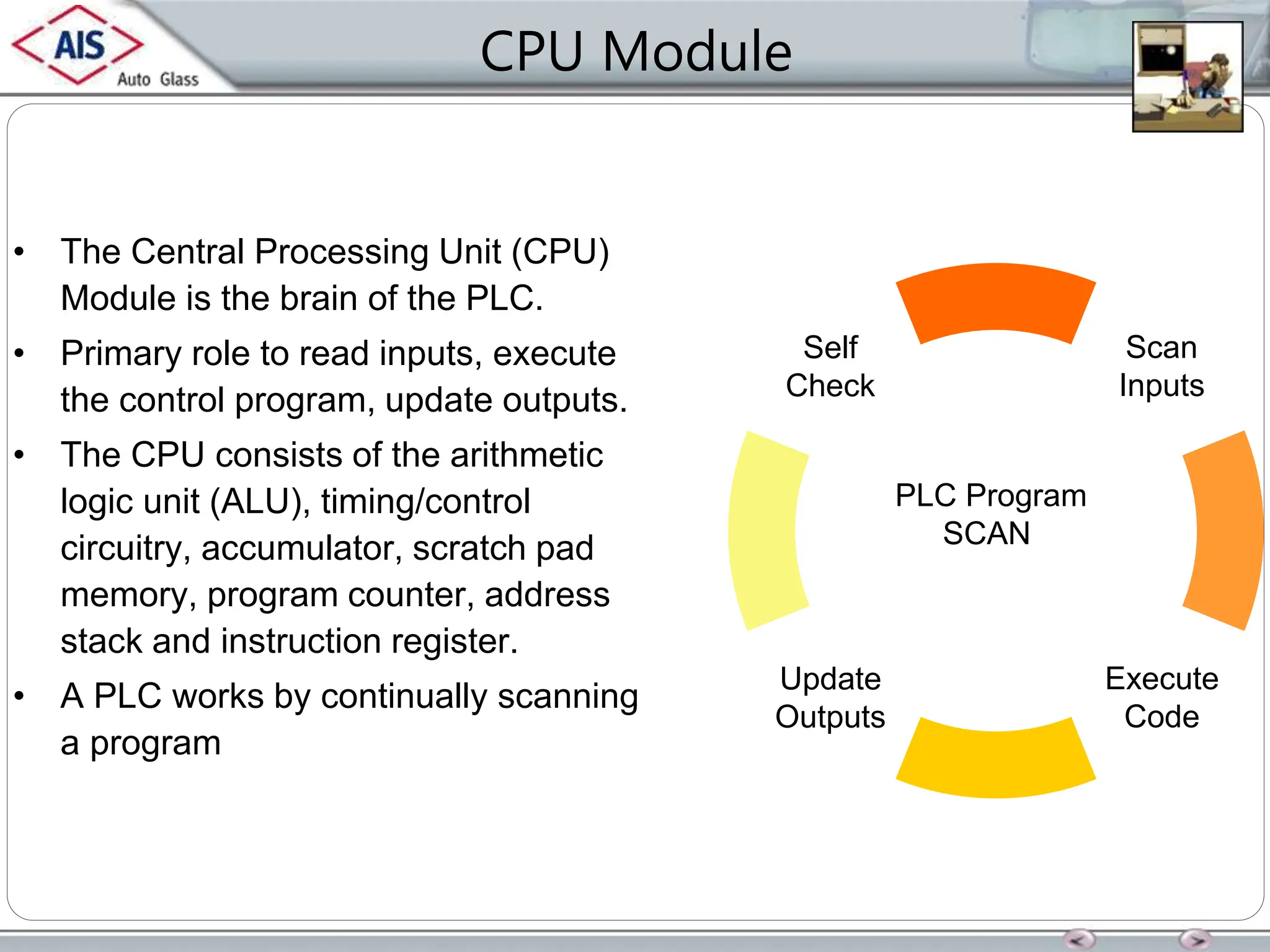

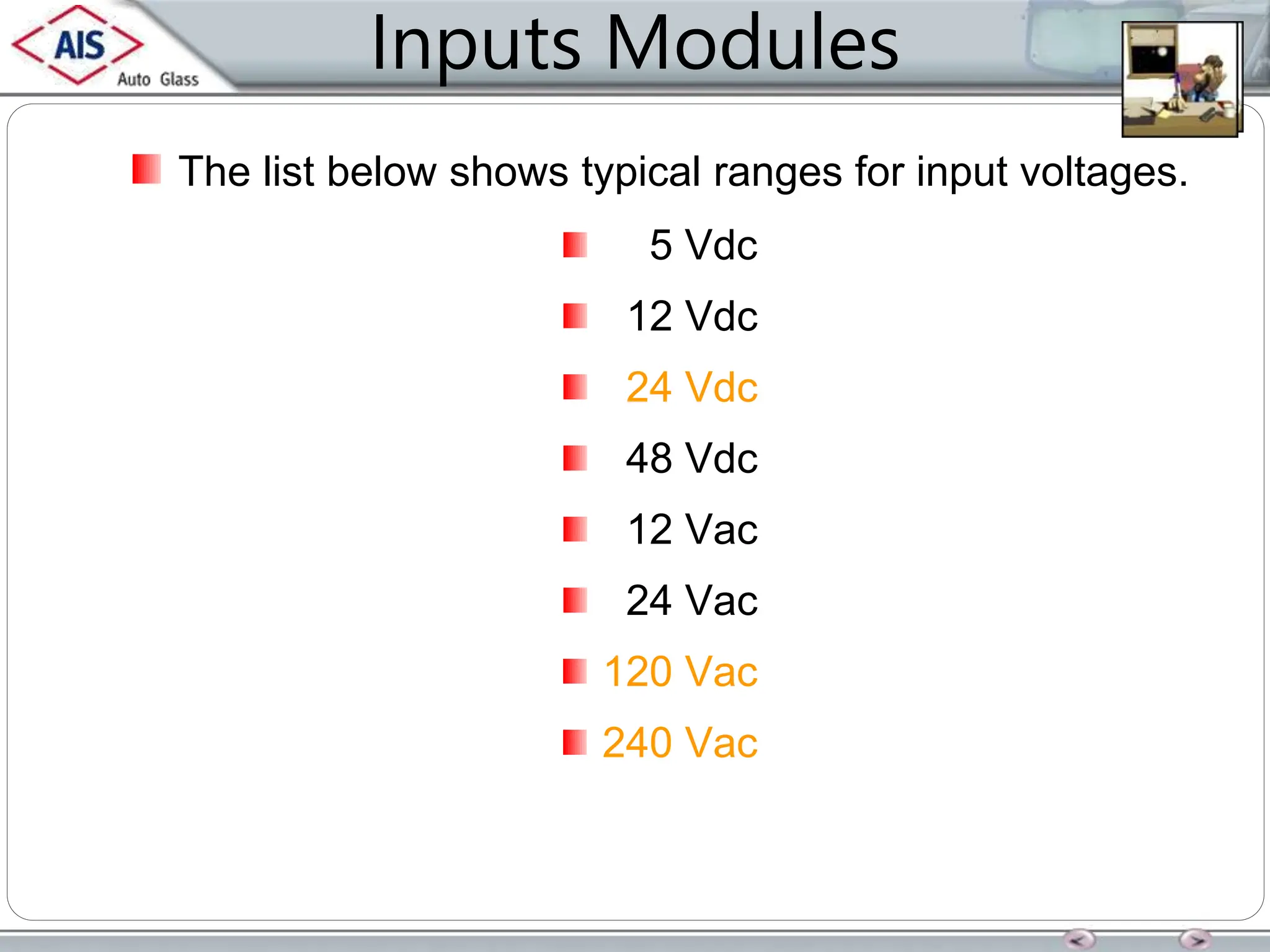

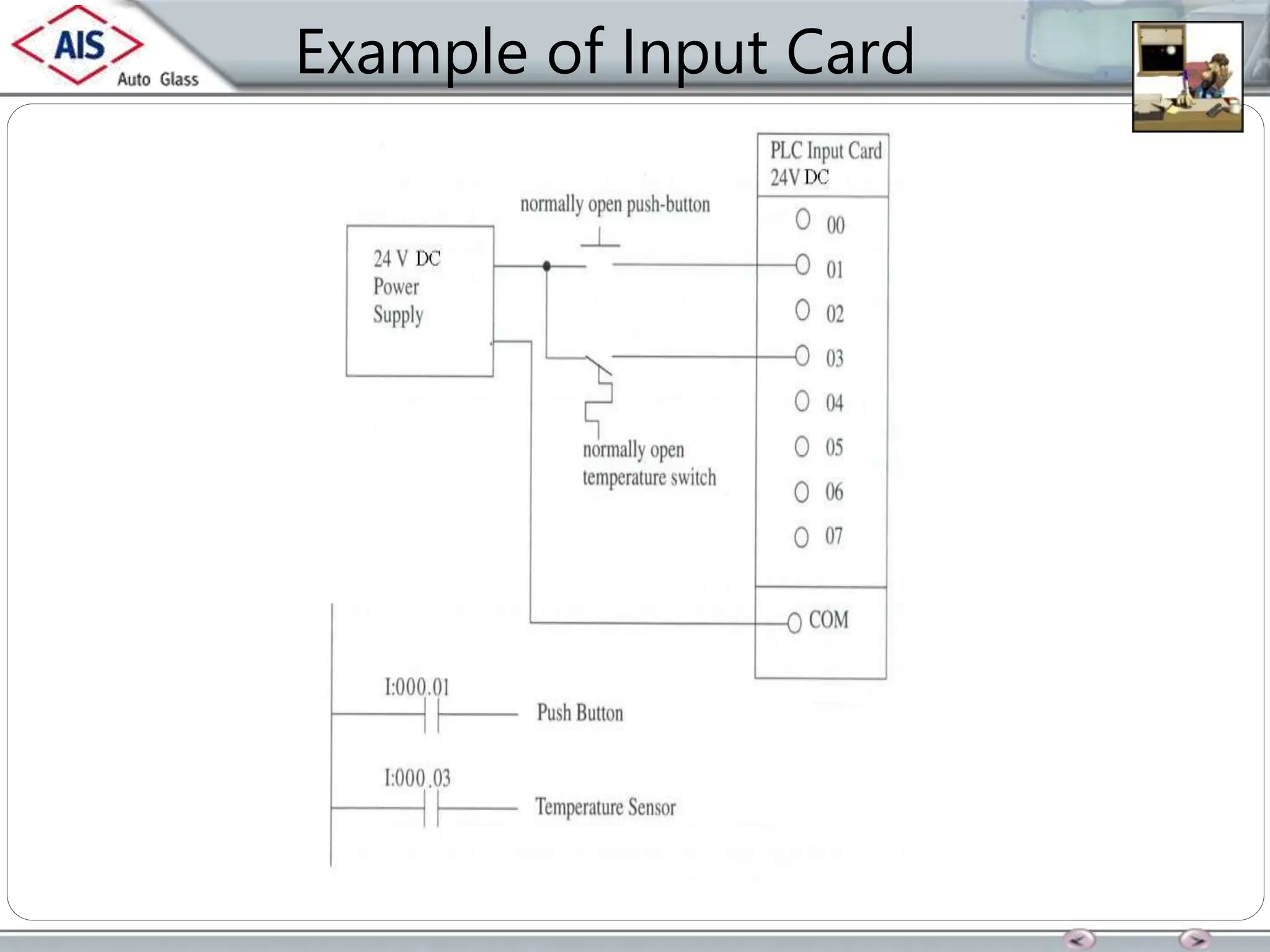

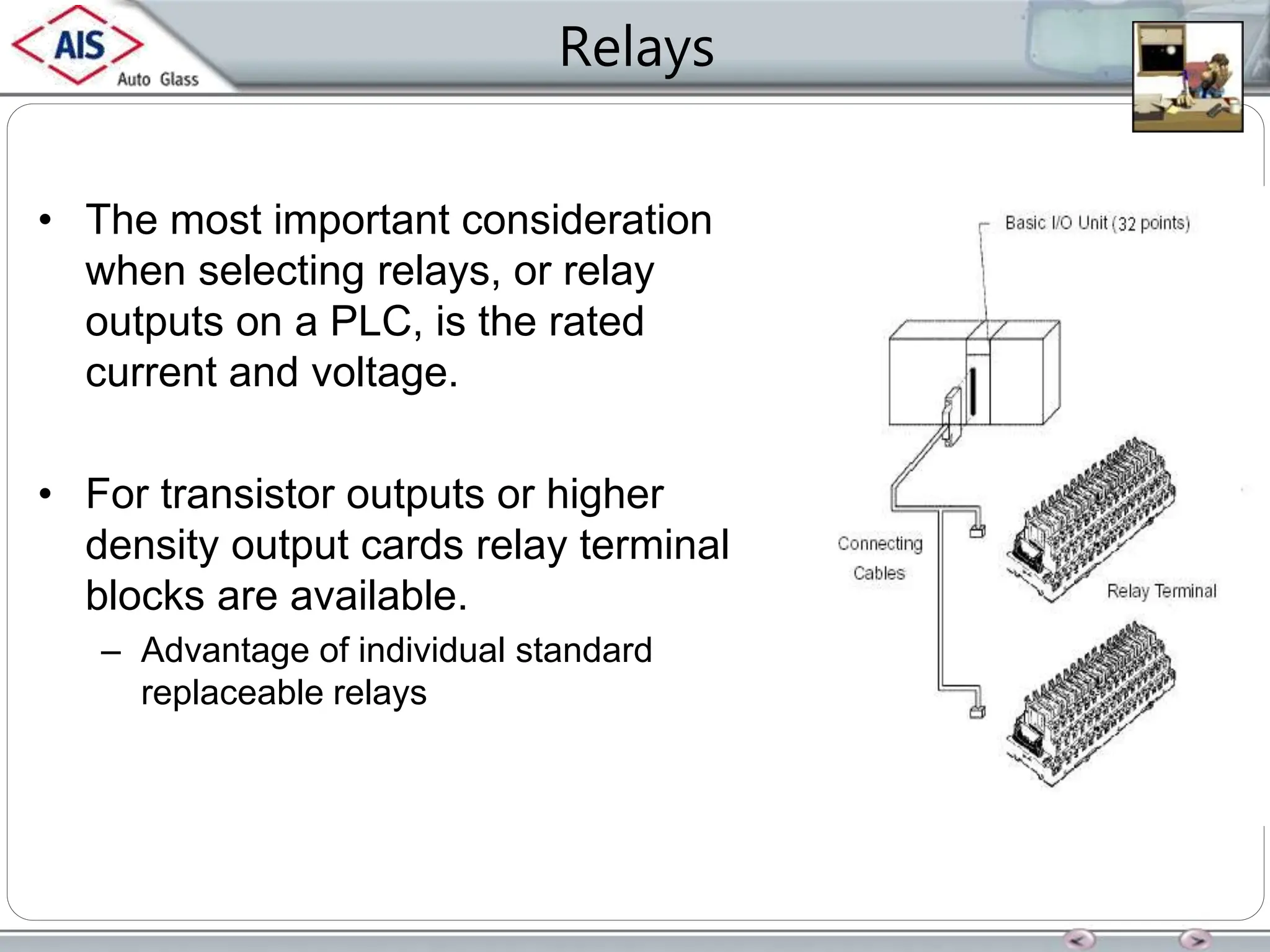

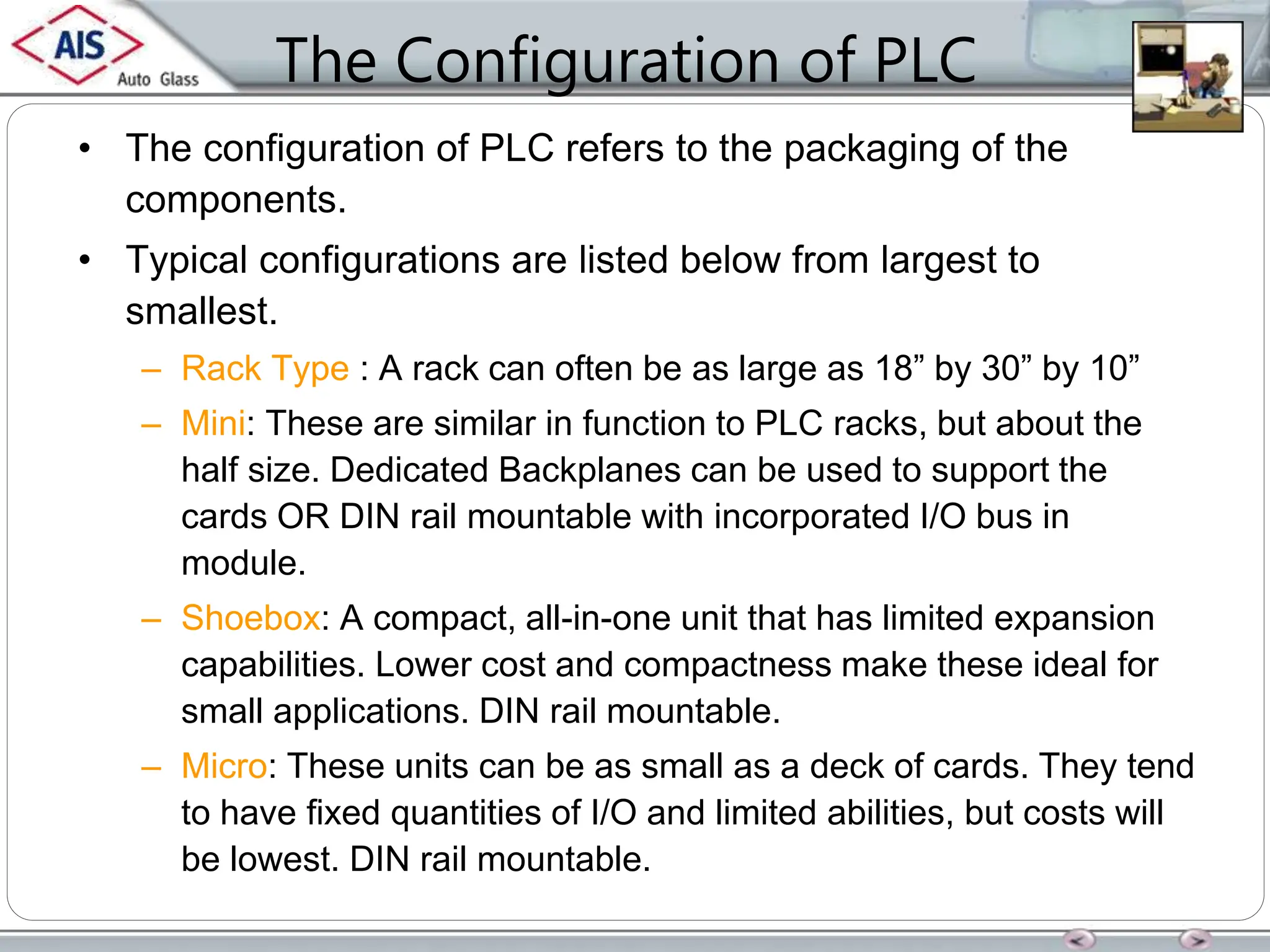

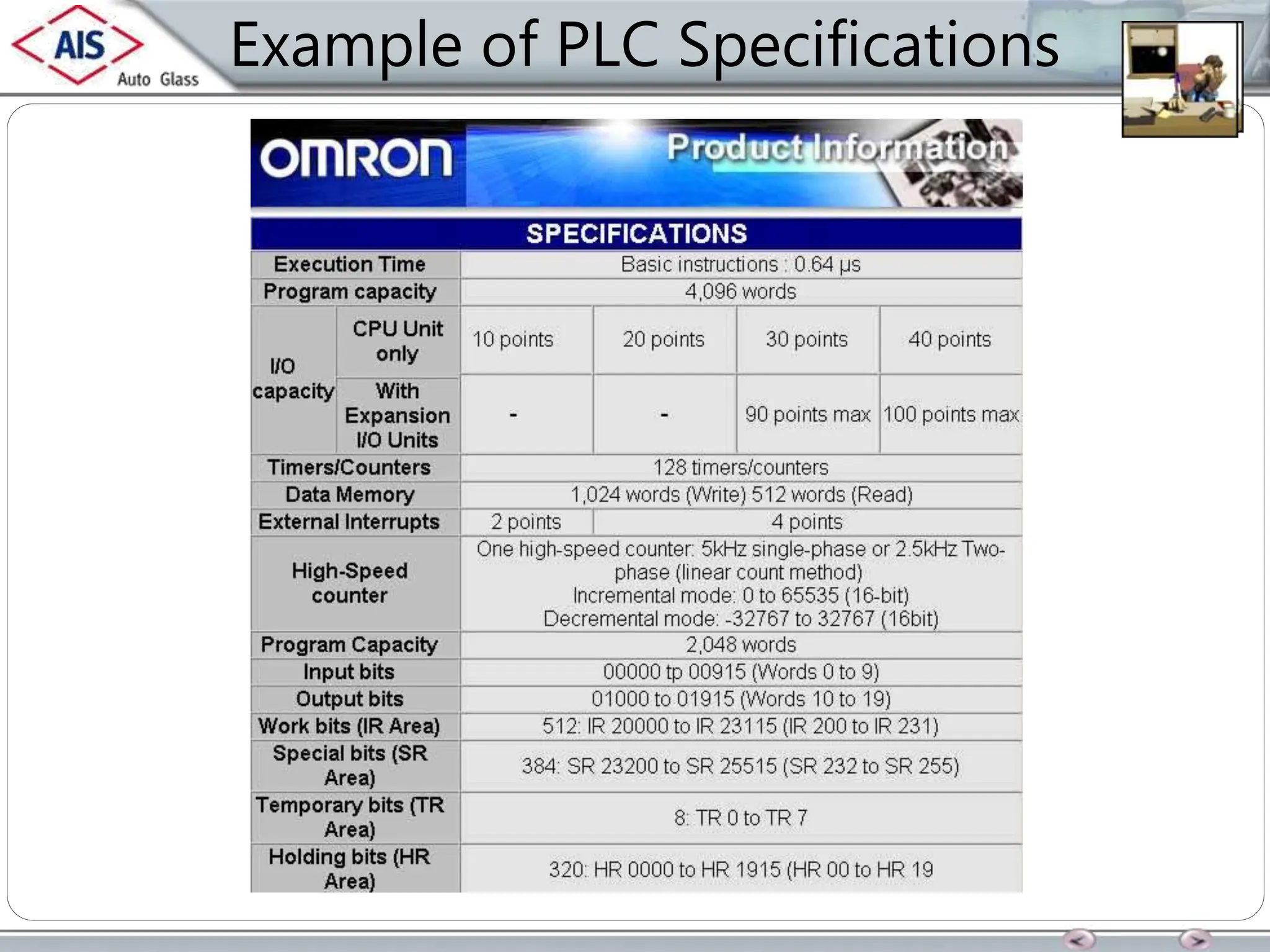

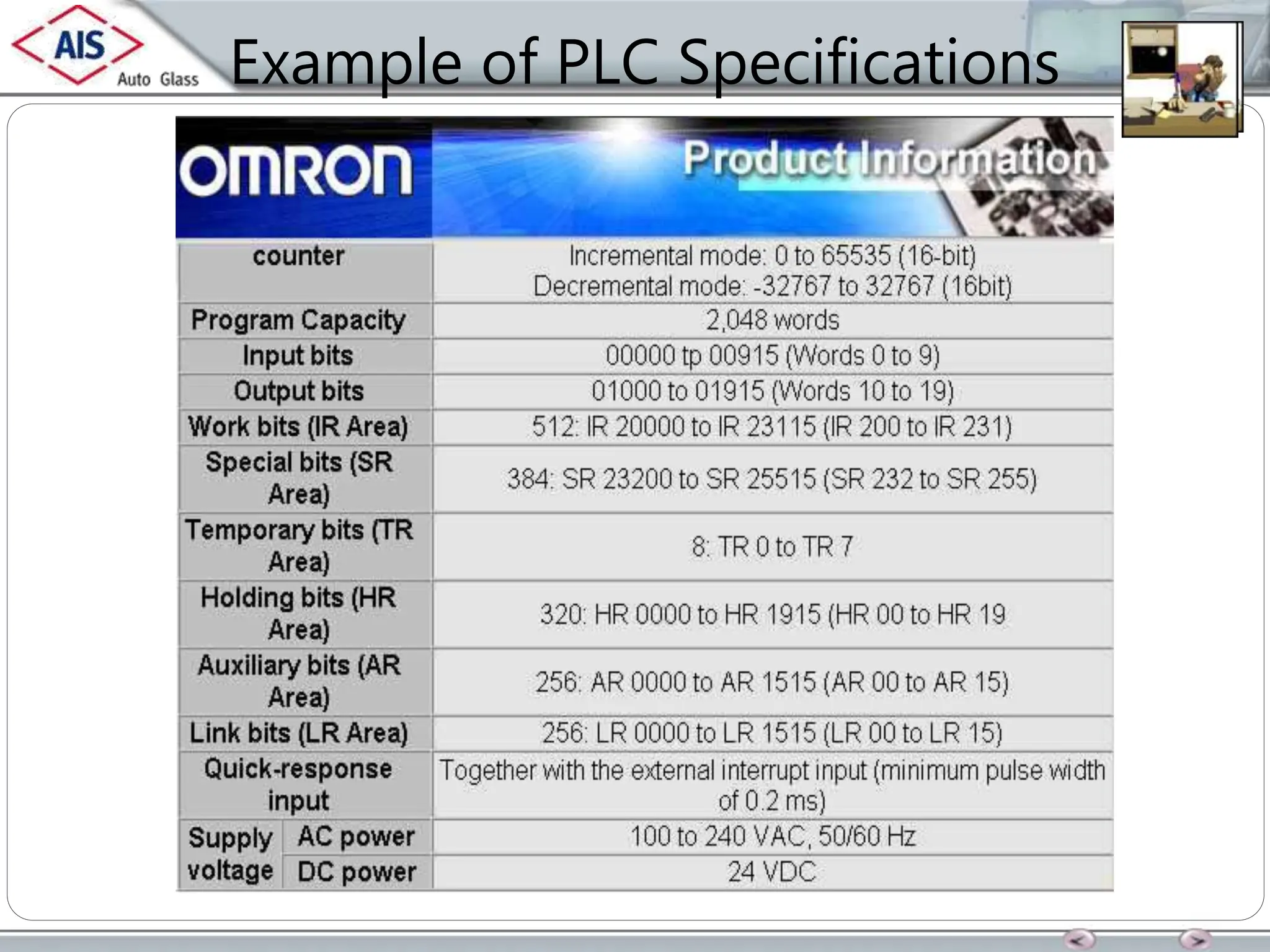

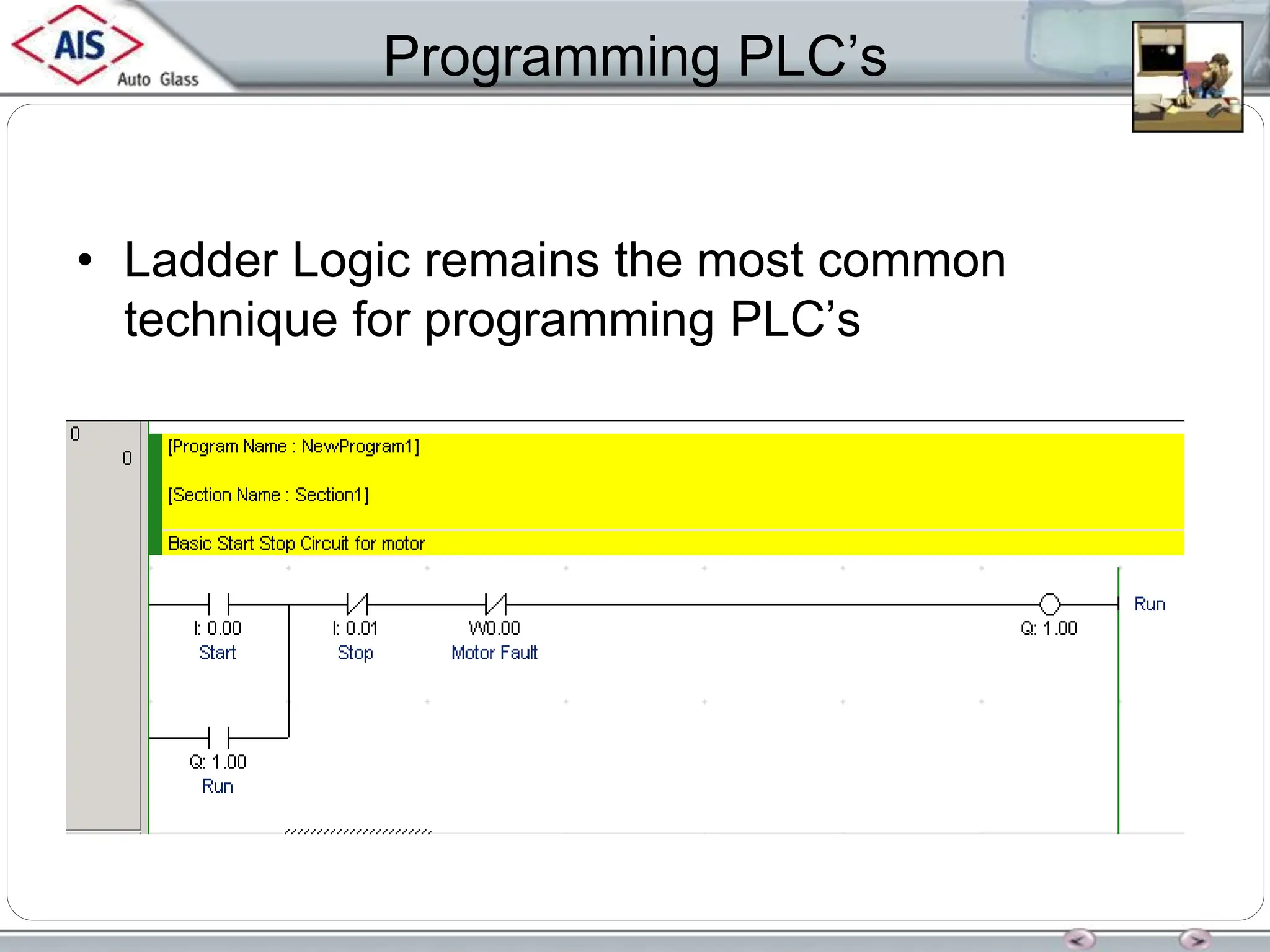

This document provides an overview of programmable logic controllers (PLCs). It describes that a PLC consists of a central processing unit and input/output modules to connect to sensors and actuators. It functions by continually scanning its program to read inputs, execute logic, and update outputs. The document outlines the basic components of a PLC including the CPU, memory, power supply, and I/O modules. It also discusses selecting a PLC based on factors like I/O counts, memory, expansion needs. Ladder logic is identified as the most common programming technique used with PLCs.