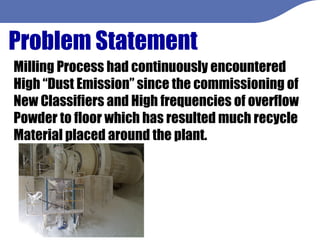

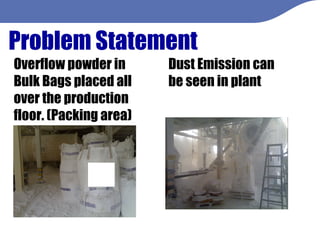

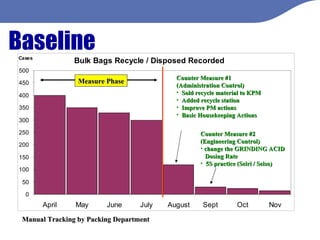

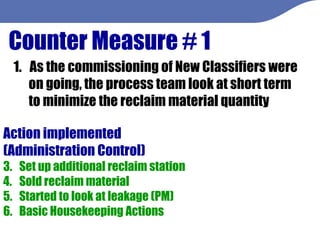

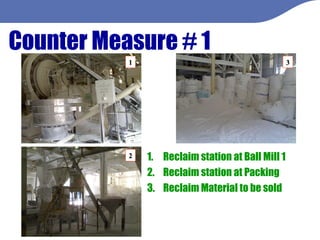

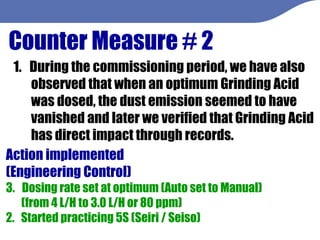

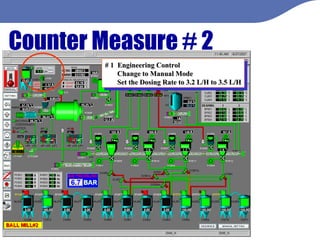

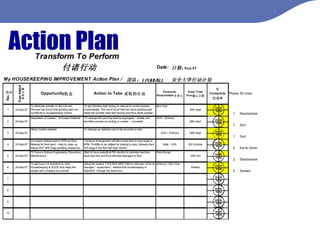

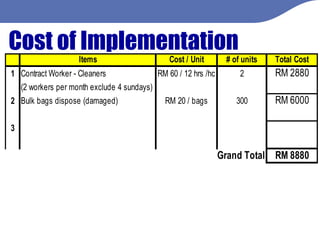

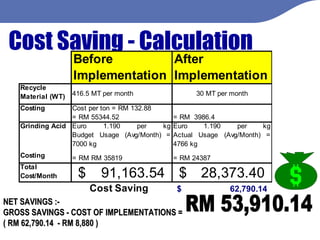

This document summarizes a continuous process improvement project at a powder plant to address high dust emissions and overflow of powder. Several countermeasures were implemented, including adding reclaim stations, selling reclaim material, optimizing grinding acid dosing, and practicing 5S. These measures led to a 71% reduction in dust emissions and overflowed material. The project cost $8,880 to implement and saved $53,910.14 per month, with additional intangible benefits like an improved work environment and knowledge gains.