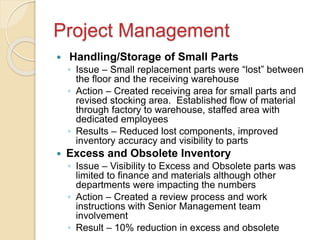

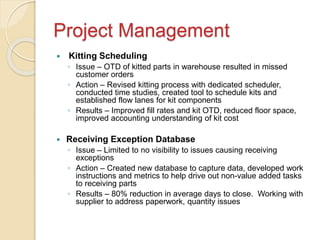

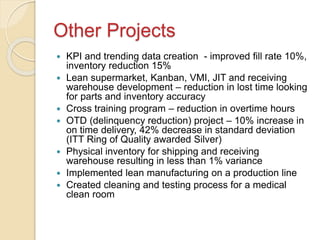

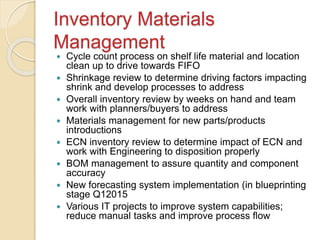

Sharise Heenan has 16 years of experience in inventory, logistics, and materials management. She has a background in lean six sigma and is working towards her CPIM certification. She has strong materials management skills and experience with new product introductions and cost reduction projects. Some of her projects include reducing material move times by 40%, freeing up 90% of warehouse space for returns, and improving inventory accuracy.