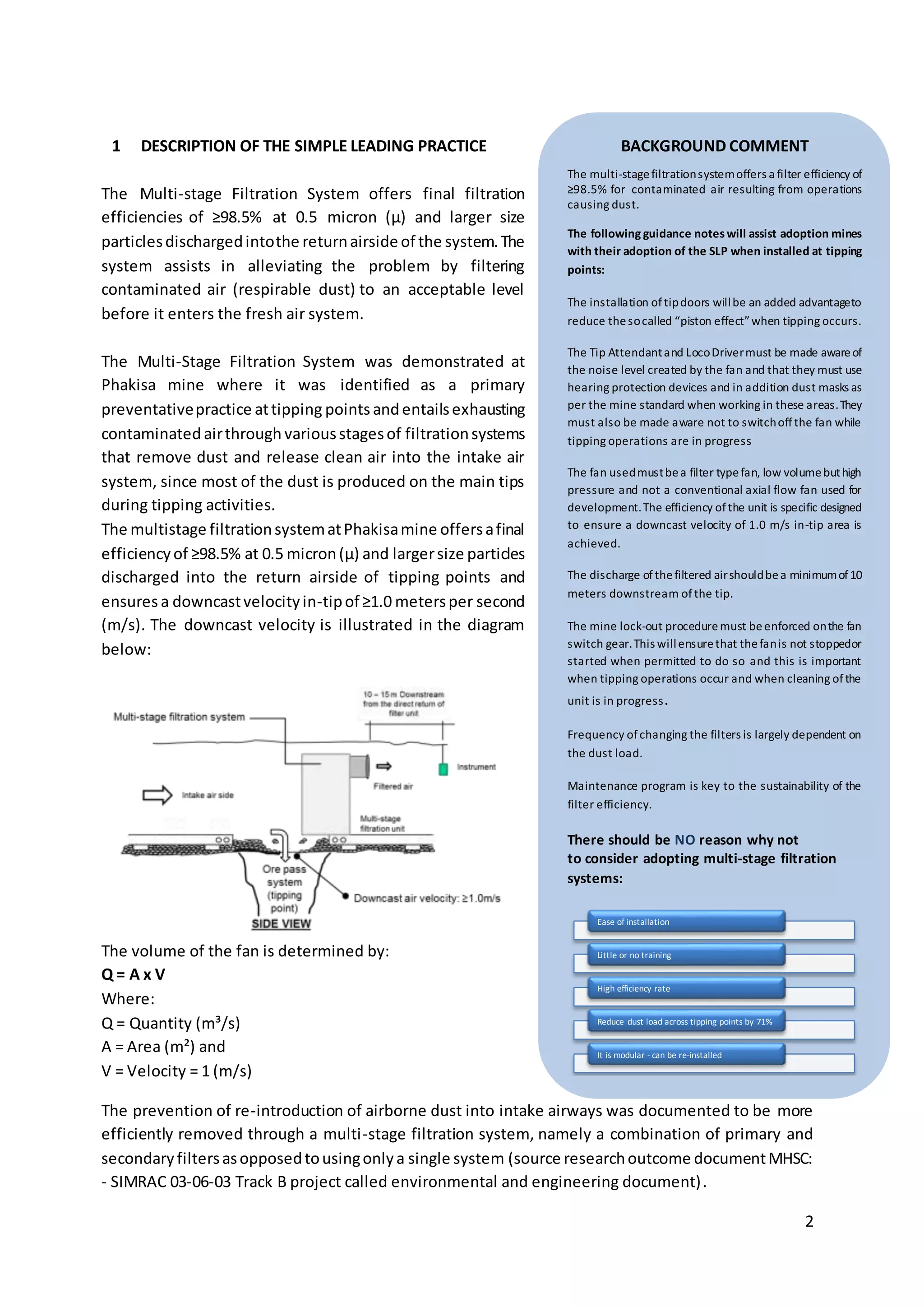

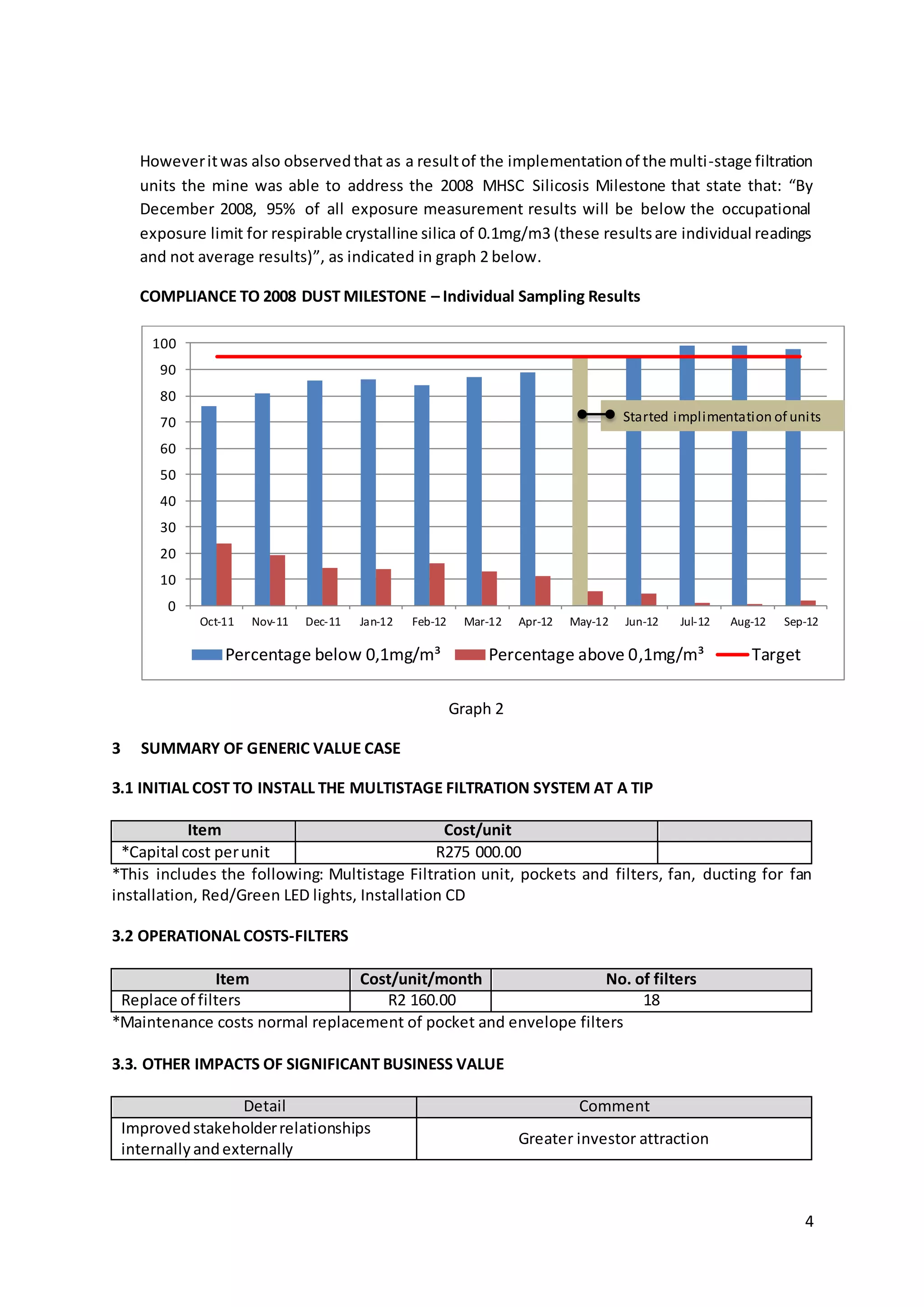

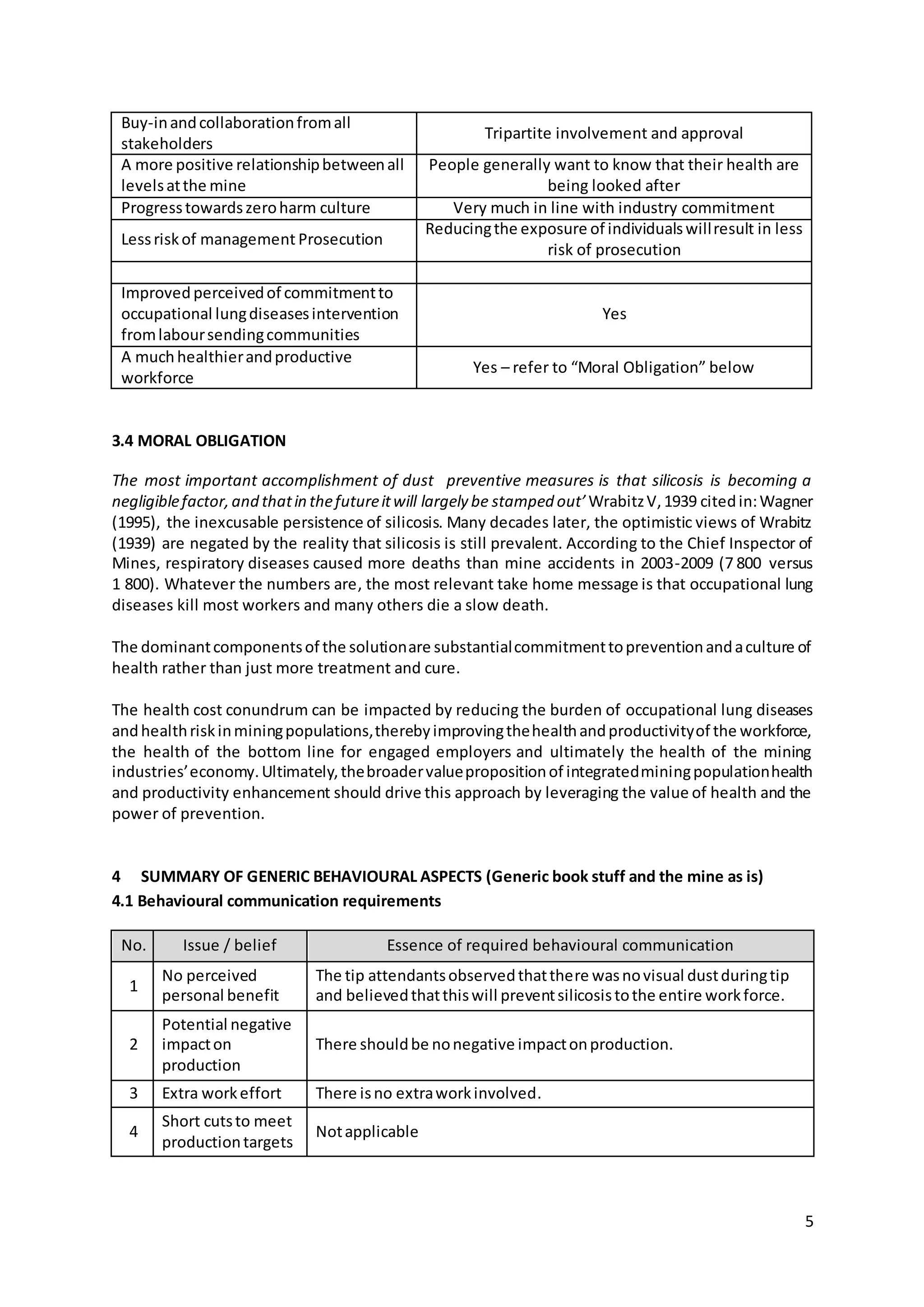

The multi-stage filtration system offers a highly efficient way to filter contaminated air from mining operations before returning it to the ventilation system. It was tested at Phakisa Mine where it reduced dust levels by 71% on average. The system uses multiple stages of filters to achieve at least 98.5% filtration of particles 0.5 microns or larger. Proper maintenance is required to sustain the filtration efficiency. While there is an initial installation cost, the system provides significant health and productivity benefits that improve stakeholder relationships and reduce business risks from occupational lung diseases.