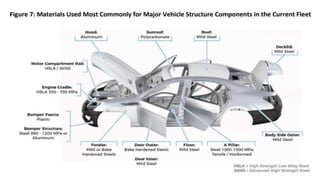

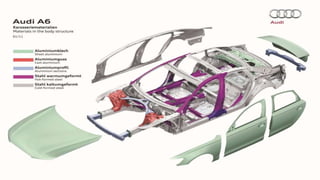

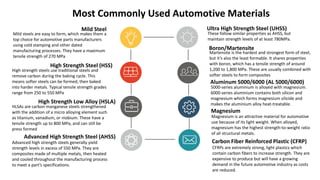

The document discusses various materials used in vehicle structures, highlighting their properties, such as strength and weight, as well as manufacturing processes. It emphasizes the trend towards lighter materials for improved fuel economy and addresses challenges in recycling and complexity of new materials. Additionally, it mentions the need for workforce training to adapt to these advancements in automotive materials.