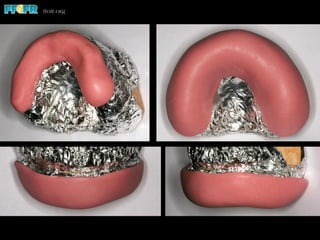

This document discusses secondary impression materials used in fixed prosthodontics. It defines an impression as a negative reproduction of prepared teeth that provides information to fabricate a crown or fixed prosthesis. Impressions can be physical materials or digital scans. Physical impressions include reversible hydrocolloid, condensation silicone, polysulfide, polyether, and addition silicone. Digital impressions involve directly scanning teeth or an indirect scan of a dental cast. Custom trays are often used to carry and confine impression materials. Trays should be rigid, dimensionally stable, and provide adequate space for materials. The document outlines techniques for fabricating custom trays using autopolymerizing or light-cured resin. Good impressions accurately record all prepared surfaces