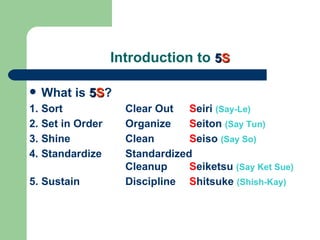

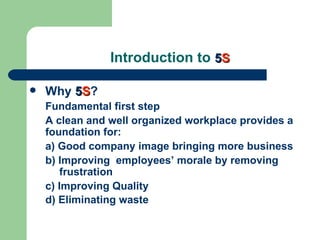

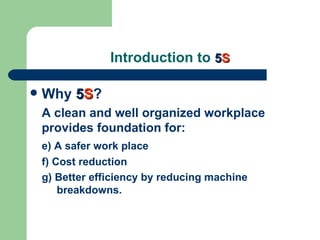

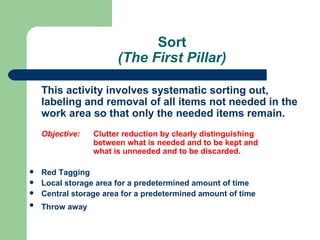

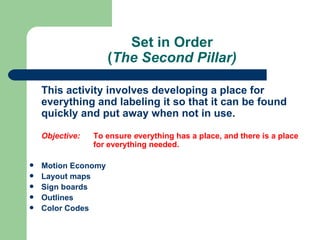

The document discusses the 5S methodology for improving workplace organization and productivity. 5S stands for Sort, Set in Order, Shine, Standardize, and Sustain. Each "S" represents an activity to clear out unneeded items, organize the workspace, clean the area, standardize processes, and sustain the 5S system through commitment. The goals are to eliminate waste, improve efficiency and safety, reduce costs, and create a foundation for quality. Implementing 5S is presented as an ongoing team-based process that establishes order and detects potential problems.