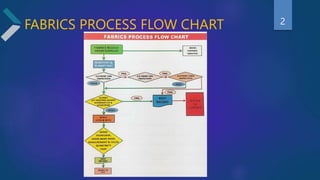

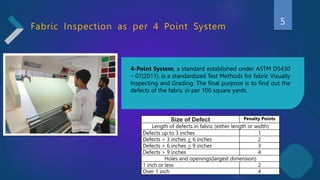

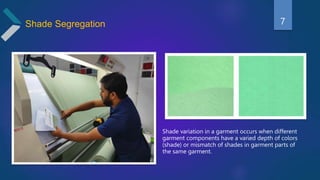

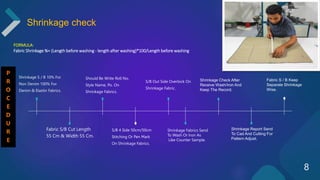

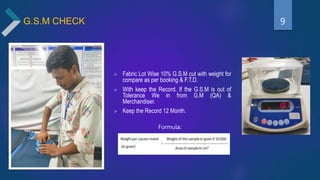

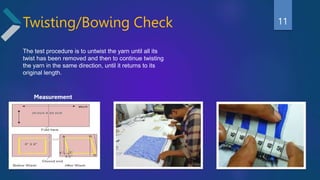

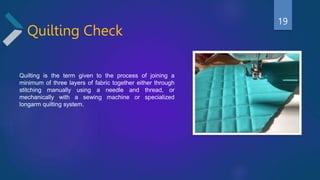

This document outlines fabric inspection procedures in 22 steps, beginning with inventory and ending with color continuity cards. Key steps include a 4-point inspection system to find defects, checking for shrinkage, GSM, shading, twisting, padding migration, various coatings, color staining, hydrostatic and DWR testing, odor, quilting, hand feel, and maintaining color continuity cards for lots printed at different times. The document provides definitions, formulas, and detailed explanations for properly conducting each inspection.