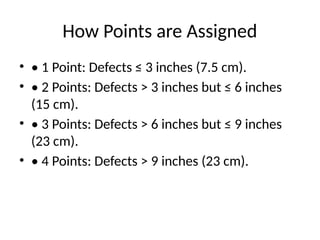

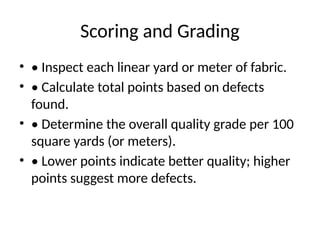

The four-point system is a standardized method for evaluating fabric quality in the textile industry by assigning points to defects based on size and severity. Defects are assessed per linear yard, allowing for effective scoring and grading to determine fabric quality. This widely accepted system facilitates consistent quality control and decision-making during fabric inspections.