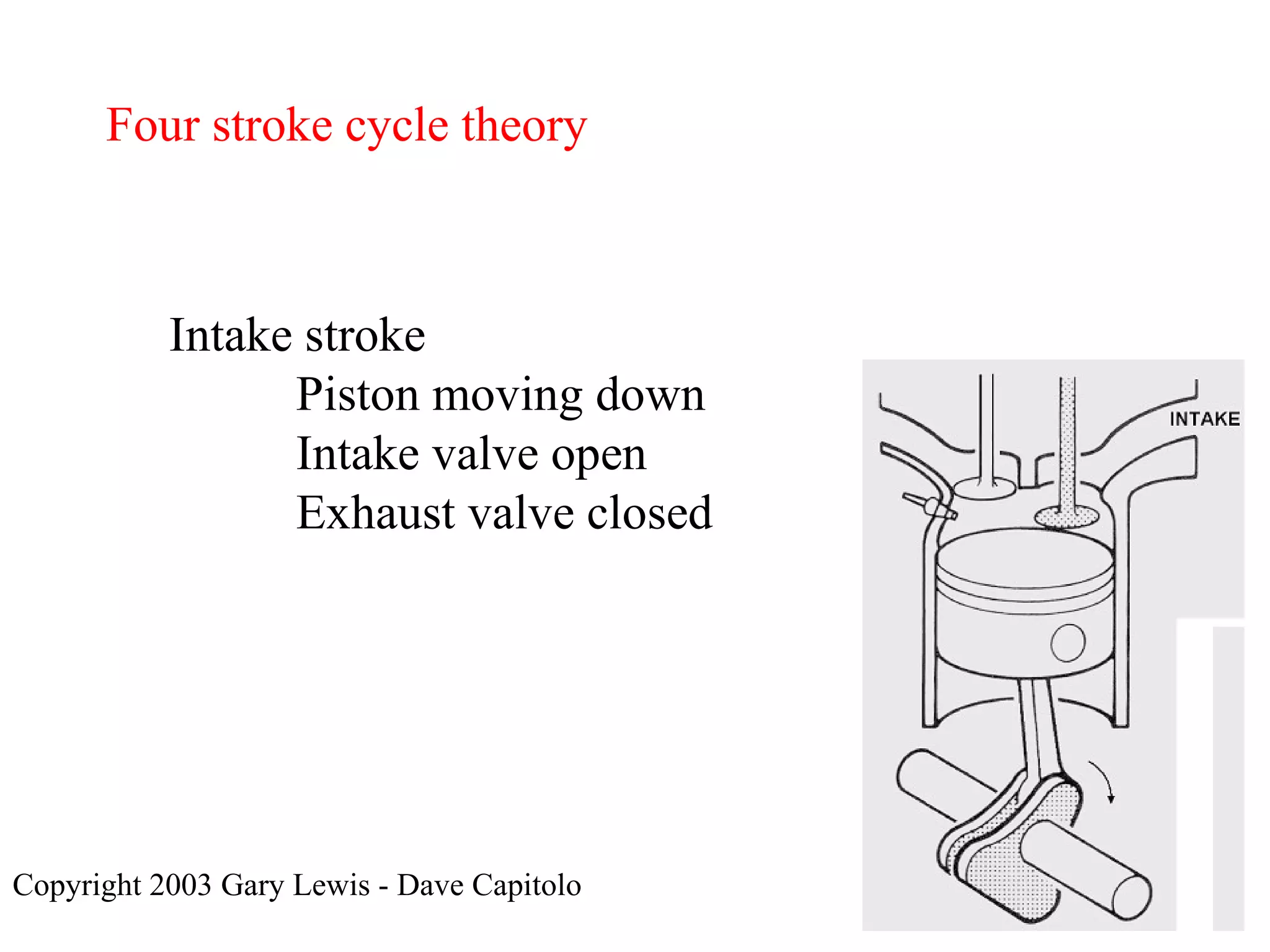

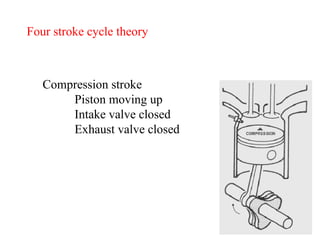

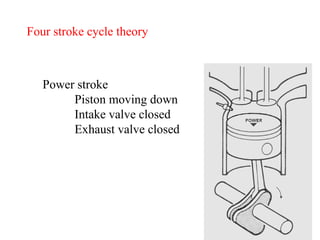

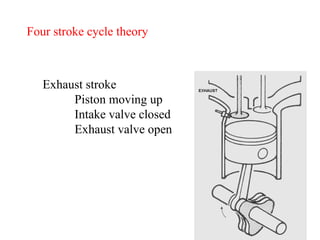

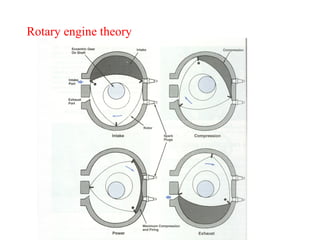

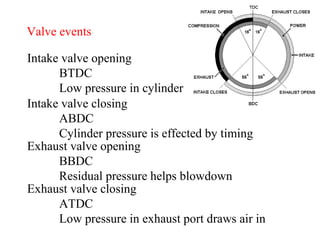

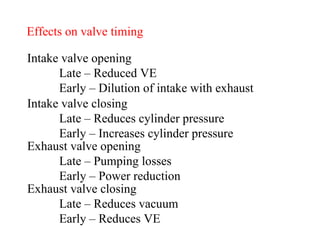

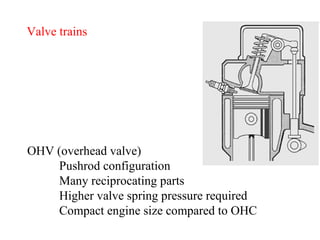

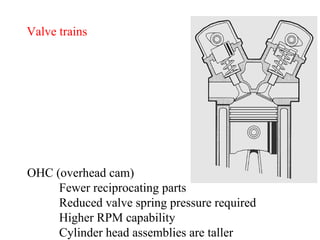

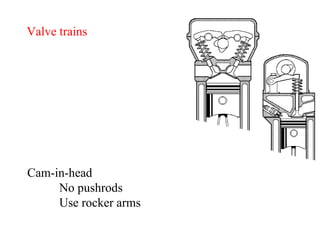

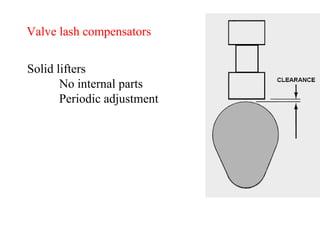

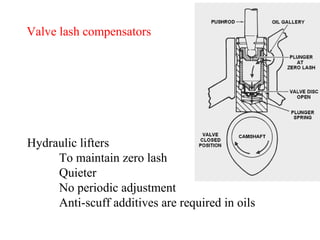

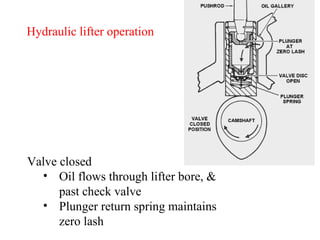

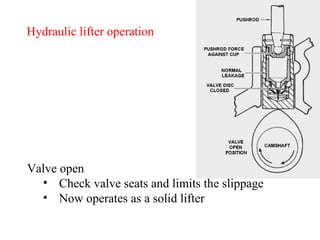

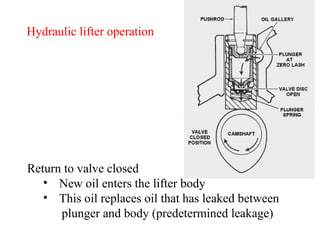

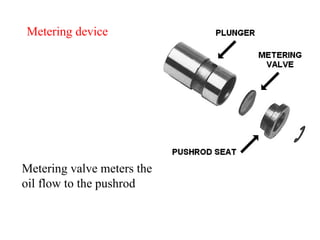

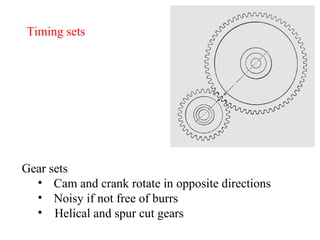

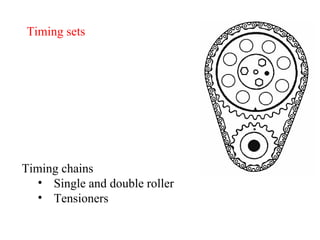

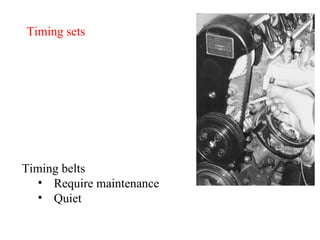

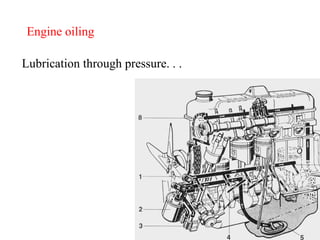

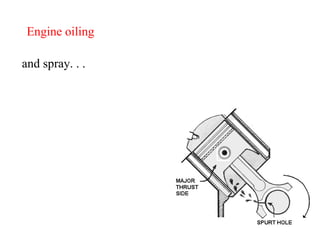

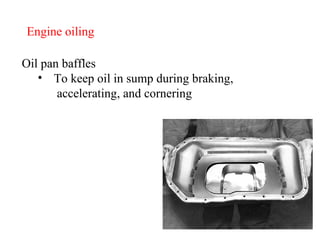

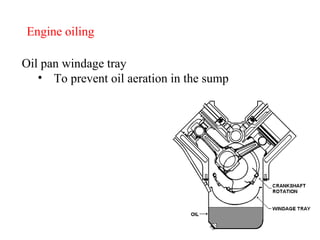

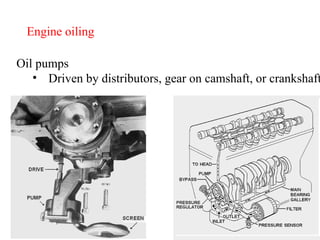

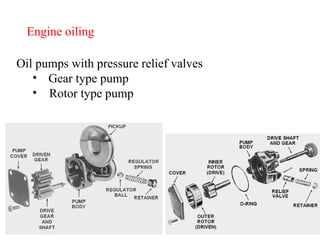

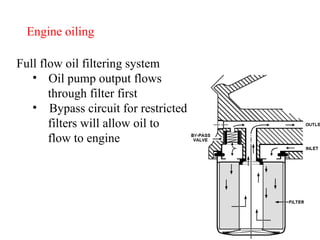

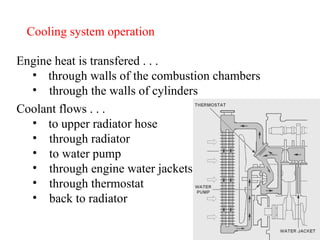

The document discusses the four stroke cycle theory of internal combustion engines. It describes the four strokes - intake, compression, power, and exhaust. Each stroke involves the piston moving up or down and the opening and closing of the intake and exhaust valves. The timing of the valve openings and closings affects engine performance. It also discusses overhead camshafts, hydraulic lifters, engine lubrication systems, cooling systems, and combustion efficiency.