Lecture 3 fp lecture notes engine2

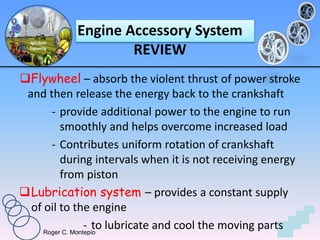

- 1. Roger C. Montepio Flywheel – absorb the violent thrust of power stroke and then release the energy back to the crankshaft - provide additional power to the engine to run smoothly and helps overcome increased load - Contributes uniform rotation of crankshaft during intervals when it is not receiving energy from piston Lubrication system – provides a constant supply of oil to the engine - to lubricate and cool the moving parts Engine Accessory System REVIEW

- 2. Roger C. Montepio Engine Accessory System REVIEW Fuel system – supplies the engine with the properly proportioned fuel and air mixture -regulates the amount of the mixture supplied to the engine to control engine speed and power output

- 3. Roger C. Montepio Ignition system – ignites the fuel and air mixture in the combustion chamber at the precise moment needed Cooling system – removes the excess heat from the engine, generated by combustion Engine Accessory System REVIEW

- 4. Roger C. Montepio Valve train/system -Operates the valves (intake and exhaust valves) -Operates the valves in timed sequence -Valve construction (L-head and in-head type) L-head constructionMechanisms consist of 1) Small gears on crankshaft, 2)half time or cam gear, 3)cam, 4)tappet or short push rod

- 5. Roger C. Montepio Parts of valve system -Raised piece on the camshaft called the camlobe -function of valve spring closes the valve after it has been opened and to hold it tightly closed against its seat

- 6. Roger C. Montepio Timing gears or chain

- 7. Roger C. Montepio Valve in-head construction -Valves are of the poppet or mushroom type -consist of flat head and stem -flat head has beveled edge called the face -beveled edge found in the cylinder block or head called the valve seat -seat angle usually 45˚, 30˚ angle is frequently used for intake valve

- 8. Roger C. Montepio Parts of engine valves head Lip/edge Face Shoulder Stem Lock groove

- 9. Roger C. Montepio When can we say that the Valve is correctly timed if a valve starts to open and then closes at specified time wrt the crankshaft and piston position Valves action is gradual, that is , the valve is pushed slowly and it open and close. This sequence are determined by: 1. Timing of crankshaft and camshaft gears 2. Shape of the cam 3. Tappet or rocker arm clearance

- 10. Roger C. Montepio Valve timing Two revolution crankshaft = 4-stroke completes the cycle (Intake, Compression, Power, Exhaust) Timing gears are arranged to allow 2-revolution crankshaft for each revolution of the camshaft Engine operate efficiently only if it is correctly timed

- 11. Roger C. Montepio Range of operation and cam shape Range of operation – number of degrees through w/c the crank rotates from the point where the valve starts to open to the point where it is just completely closed - 235 to 240 degrees - determined by: 1. camshaft shape (if angle of action and cam lobe height/lift are greater and longer – wide range of operation) 2. valve clearance (too much – decrease the range of operation)

- 12. Roger C. Montepio Valve clearance - space allowed between the end of the valve stem and rocker arm (In-head type) - space allowed between the valve stem and the tappet (L-head type) Too much valve clearance would produce a very pronounce noise Type Intake Exhaust Auto engine 0.006-0.012 inch 0.010-0.020 inch Tractor engine 0.010-0.020 inch 0.012-0.030 inch

- 13. Roger C. Montepio What are the effects of incorrect valve timing? - longer time of valve opening, would results to a generation of more power and operate efficiently - short time (vice versa) - high-speed engine closes as much as 45˚ to 60˚ after BDC Incorrect intake valve timing

- 14. Roger C. Montepio What are the effects of incorrect valve timing? - earlier time of valve opening, results to a more satisfactory, it gives: 1. more power, 2. run cooler, 3. uses less fuel, and 4. better cleaning of cylinder - too late time - overheating - most engine open 45˚ before BDC Incorrect exhaust valve timing

- 15. Roger C. Montepio Fuel Supply and Carburetion System In gasoline engine, fuel is admitted into the cylinder of the engine by the carburetion process. Carburetion process takes place in the carburetor

- 16. Roger C. Montepio Carburetors Purpose of the carburetor is to produce a mixture of fuel and air on which the engine can operate Supply definite proportion / metered to suit fuel requirements of the engine Air-fuel ratio: 1:2 ratio when the engine is started 1:9 ratio during cruising/traveling speed

- 17. Roger C. Montepio Carburetors Idling speed- speed of the engine in which butterfly valve partially closed, only a limited amount of air is admitted and only idling jet operates to supply minimal amount of fuel Must produce economical fuel consumption and smooth engine operation over a wide range of speeds Requires complicated device rather than a simple mixing valve; price is very important!

- 18. Roger C. Montepio Venturi (nozzle) • Use force of atmospheric pressure and artificially created low pressure area to mix fuel and air • Use a venturi nozzle to lower air pressure in carburetor to create suction to “pull” fuel into air Venturi (nozzle) P+1/2 V2 = ConstantBernoulli Principle:

- 19. Roger C. Montepio Venturi-type Carburetor Ref. Obert Constant level is maintained in bowl -as float moves down, valve stem moves down, allowing more fuel into bowl, float moves up and closes valve Valve StemFuel Inlet Float Metering Orifice Throttle Plate Air/Fuel Mixture To Engine Choke Plate Fuel Nozzle Inlet Air Bowl Atomized Fuel Venturi

- 20. Roger C. Montepio Flo-Jet Carburetor • Fuel tank is above carburetor • Fuel is fed directly to carburetor by gravity • Vent connected to float (fuel chamber or cup) …..Why the vent?

- 21. Roger C. Montepio Flo-Jet Carburetor Fuel from tank Air flow Air-fuel mixture

- 22. Roger C. Montepio Pulsa-Jet Carburetor • Incorporates a diaphragm type fuel pump and a constant level fuel chamber

- 23. Roger C. Montepio Pulsa-Jet Carburetor Operation Intake stroke of piston creates a vacuum in carburetor elbow Pulls cap A and pump diaphragm B inward and compresses spring Vacuum thus created on “cover side” of diaphragm pulls fuel up suction pipe S into intake valve D

- 24. Roger C. Montepio Pulsa-Jet Carburetor Operation When engine intake stroke is complete, spring C pushes plunger A outward Gasoline in pocket above diaphragm to close inlet valve D and open discharge valve E Fuel is then pumped into fuel cup F

- 25. Roger C. Montepio Pulsa-Jet Carburetor Operation Venturi in carburetor is connected to intake pipe I which draws gasoline from fuel cup F Process is repeated on the next stroke, keeping the fuel cup full Since fuel cup level is constant, engine gets constant air-fuel ratio

- 26. Roger C. Montepio Fuel Injection in CI Engines Fuel injection is a critical process in CI engines Injection pump use to deliver individual fuel injections via high strength lines to injectors. Classed of injection of fuels into the engine cylinder 1. directly 2. indirectly Basic objectives - to atomize and inject the fuel - provide right quantity at right time

- 27. Roger C. Montepio Modern Fuel Injection System Electronic injection system Electronic control unit controls the timing and duration of injections by opening solenoid valves Injection timing and duration can be customized to meet various objectives, including maximizing power or fuel economy or minimizing exhaust emissions

- 28. Roger C. Montepio Fuel injection system components Gravity feed injection pump of a diesel engine Day-tank Stop cork/fuel valve Fuel line Primary and secondary Fuel filter Cam follower Transfer pump, Injection pump and injector unit High pressure fuel line Nozzle INJECTOR UNIT- fuel injector and meterer at the same time NOZZLE - atomizer

- 29. Roger C. Montepio Injection pump and unit injector Injection pump Considered as the heart of diesel engine Delivers the needed amount of fuel at proper time and form Operates at high hydraulic pressure at ranges from 70 to 700 kg/cm2 Basic parts: 1. Plunger 2. Barrel It operates very much alike that of the syringe

- 30. Roger C. Montepio Methods of controlling the amount of fuel Depends upon the length of plunger stroke Depends on the manner of bypassing the excess fuel from the barrel The variation of the plunger stroke and by- passing of fuel from the barrel is acted on by the GOVERNOR

- 31. Roger C. Montepio Governing system GOVERNOR a device that controls the speed of the engine Varies the air or fuel supply requirement of the engine Types of governor Hydraulic /pneumatic controlled Mechanically controlled

- 32. Roger C. Montepio GOVERNOR Three physical principles involved in which the governors will work Creating vacuum – pneumatic controlled governor Creating hydraulic pressure – hydraulic controlled governor Creating centrifugal force – mechanical controlled governor

- 33. Roger C. Montepio Mechanical Governor Works alike the principle of the sling Consists of flyweights, sleeve, yoke, and return spring The mechanical governor drive gear engages with the engine camshaft. The drive gear turns the entire governor assembly. The flyweights move outward from the drive shaft axis as the governor assembly turns. There is then a chain of movements to the sleeve, yoke, control rack and finally with the plunger w/c is a part of the injection pump that controls the amount of fuel for the engine.

- 34. Roger C. Montepio Lubrication system The lubrication system supplies a constant supply of oil to all moving parts constant supply of fresh oil is to minimize wear, flush bearing surfaces clean remove the localized heat that develops between moving parts as a result of friction oil that is supplied to the cylinder walls helps the piston rings make a good seal to reduce blowby

- 35. Roger C. Montepio Ignition system

- 36. Roger C. Montepio Purpose of Lubrication a. Oil as a Lubricant. primary function of engine oil is to reduce friction between moving parts (lubricate) Without lubrication?????????? Lubrication system

- 37. Roger C. Montepio Without lubrication addition to wasting engine power, creates destructive heat and rapid wear of parts or (melts) greater energy required to overcome that friction Purpose of Lubrication b. Oil as a Coolant. also serves to remove heat from the friction points Lubrication system

- 38. Roger C. Montepio 1) How Oil Lubricates (a) oil is fed to the surface it forms a film, preventing the moving part from actually touching the surface (b) As a part rotates, the film of oil acts as a series of rollers It is important that sufficient clearance be allowed between the part and the bearing; otherwise the film might be too thin. It also is important that the clearance not be too large between rotating parts and their bearings – cause bearing failure Lubrication system

- 39. Roger C. Montepio How Oil Lubricates

- 40. Roger C. Montepio (2) Oil Contamination Lubrication system Oil does not wear out, but it does become contaminated How oil becomes contaminated?????? foreign matter enters through the air intake, will pass by the piston rings enter the crankcase CASE 1

- 41. Roger C. Montepio combined with foreign matter entering through the crankcase breather pipe mixes with the oil, forced into the bearings, Water will emulsify with the oil to form a thick sludge crankcase (2) Oil Contamination Lubrication system CASE 2 products of combustion is WATER, condense in the crankcase will seep by the piston rings as steam

- 42. Roger C. Montepio How oil becomes contaminated??????

- 43. Roger C. Montepio Lubrication system (2) Oil Contamination What happen when the oil, mixed with the contaminants? loses its lubricating qualities Becomes acidic Engine oil must be changed periodically to prevent contaminated oil from allowing excessive wear and causing etching of bearings

- 44. Roger C. Montepio How to control engine contamination a) Control engine temperature; b) The use of oil filters c) An adequate crankcase ventilation system d) The use of air intake filters

- 45. Roger C. Montepio Oil Dilution Engine oil thins out when mixed with gasoline, causing a dramatic drop in its lubricating qualities Some of the causes of oil dilution are the following: (a)Excessive use of a hand choke (b)defective ignition system (c)a malfunctioning thermostat, or an engine that is operated for short durations only, Lubrication system

- 46. Roger C. Montepio American Petroleum Institute (API) Rating System. Lubrication system The API system for rating oil classifies oil according to its performance characteristics (quality). The higher rated oils contain additives that provide maximum protection against rust, corrosion, wear, oil oxidation, and thickening at high temperatures. six oil classifications for gasoline engines (SA, SB, SC, SD, SE, and SF) four classifications for diesel engines (CA, CB, CC, and CD).

- 47. Roger C. Montepio API Designations Lubrication system (a)SA (Utility Gasoline Engines). Adequate for utility engines subjected to light loads, moderate speeds, and clean conditions. SA-rated oils generally contain no additives. (b) SB (Minimum Duty Gas Automotive) Adequate for automotive use under favorable conditions (light loads, low speeds, and moderate temperatures) with relatively short oil change intervals. SB-rated oils generally offer minimal protection to the engine against bearing friction, corrosion, and oil oxidation.

- 48. Roger C. Montepio API Designations Lubrication system (c) SC. Meets all automotive manufacturers' requirements for vehicles manufactured from 1964 to 1967. (d) SD. Meets all automotive manufacturers' requirements for vehicles manufactured from 1968 to 1970. SD oil offers additional protection over SC oils, necessary with the introduction of emission controls.

- 49. Roger C. Montepio (e) SE. Meets all automotive manufacturers‘ requirements for vehicles manufactured from 1971 to 1979. API Designations Lubrication system (f) SF. Meets all automotive manufacturers' requirements for vehicles manufactured after 1980. SF oil is designed to meet the demands of the small, high- revving engines made necessary by the trend toward smaller vehicles. An SF oil can be used in all automotive vehicles.

- 50. Roger C. Montepio Viscosity and Viscosity Measurement. Lubrication system viscosity of an oil refers to its resistance to flow When oil is hot, it will flow more rapidly than when it is cold In cold weather, oil should be thin (low viscosity) to permit easy flow In hot weather, oil should be heavy (high viscosity) to permit it to retain its film strength

- 51. Roger C. Montepio Viscosity Measurement Lubrication system Oils are graded according to their viscosity by a series of Society of Automotive Engineers (SAE) numbers. The viscosity of the oil will increase progressively with the SAE number. SAE 5 oil would be very light (low viscosity) SAE 90 oil would be very heavy (high viscosity) oil used in gasoline engines generally ranges from SAE 5 (arctic use/colder region) to SAE 60 (desert use).

- 52. Roger C. Montepio Lubrication system The viscosity number of the oil is determined by heating the oil to a predetermined temperature and allowing it to flow through a precisely sized orifice while measuring the rate of flow. The faster an oil flows, the lower the viscosity The testing device is called a viscosimeter. Any oil that meets SAE low temperature requirements will be followed by the letter W. An example would be SAE 10W. Viscosity Measurement

- 53. Roger C. Montepio Multiweight Oils are manufactured to be used in most climates because they meet the requirements of a light oil in cold temperatures and a heavy oil in hot temperatures viscosity rating will contain two numbers An example of this would be 10W-30 An oil with a viscosity rating of 10W-30 would be as thin as a 10W-weight oil at 0° F (-17.7° C) and as thick as a 30- weight oil at 210° F (99° C). Lubrication system

- 54. Roger C. Montepio Detergent Oils Oil contain additives that help keep the engine clean by preventing the formation of sludge and gum All SE and SF oils are detergent oils Lubrication system

- 55. Roger C. Montepio Oil Pumps Lubrication system mounted either inside or outside of the crankcase, depending on the design of the engine They are usually mounted so that they can be driven by a worm or spiral gear directly from the camshaft Oil pumps generally are of: the gear the rotor type.

- 56. Roger C. Montepio Lubrication system Oil Pumps RotorType Oil Pump The rotor oil pump makes use of an inner rotor with lobes that match similarly shaped depressions in the outer rotor

- 57. Roger C. Montepio GearType Oil Pump Gear-type oil pumps have a primary gear that is driven by an external member, and which drives a companion gear Oil Pumps Lubrication system

- 58. Roger C. Montepio Oil Strainer and Pickup Lubrication system Strainer/ screen is usually a fine mesh bronze screen, located in the oil sump on the end of the oil pickup tube The oil pickup tube is then threaded directly into the pump inlet or may attach to the pump by a bolted flange A fixed-type strainer, like the one described, is located so that a constant supply of oil will be assured The pickup is designed to float on top of the oil, thus preventing sediment from being drawn into the oiling system.

- 59. Roger C. Montepio Lubrication system Oil Strainer and Pickup figure

- 60. Roger C. Montepio Oil Filters. Lubrication system removes most of the impurities that have been picked up by the oil as it is circulated through the engine The filter is mounted outside the engine and is designed to be readily replaceable Two basic filter element configurations: the cartridge-type the sealed cam-type

- 61. Roger C. Montepio Oil Filters. Lubrication system

- 62. Roger C. Montepio Lubrication system Oil Filters. (a) cartridge-type filter element fits into a permanent metal container The element is changed easily by removing the cover from the container when this type of filter is used (b) sealed cam-type filter element is completely self-contained, consisting of an integral metal container and filter element. This type of filter is screwed onto its base and is removed by spinning it off

- 63. Roger C. Montepio Filter Medium Materials Lubrication system most popular automotive filter mediums 1. Cotton waste 2. resin-treated paper They are held in place by sandwiching them between two perforated metal sheets 3. layers of metal that are thinly spaced apart for heavy-duty applications

- 64. Roger C. Montepio Filter Medium Materials Lubrication system

- 65. Roger C. Montepio Filter System Configurations. Lubrication system Two-filter system configurations the full-flow system bypass system. Operation (a)full-flow system the most popular in current automotive design All oil in a full-flow system is circulated through the filter before it reaches the engine It incorporate a bypass valve in the oil filter to allow the oil to pass through the element in the event it becomes clogged. This will prevent the oil supply from being cut off to the engine.

- 66. Roger C. Montepio (a)full-flow system Filter System Configurations.

- 67. Roger C. Montepio (b) bypass system diverts only a small quantity of the oil each time it is circulated and returns it directly to the oil pan after it is filtered. Filter System Configurations. Lubrication system

- 68. Roger C. Montepio Lubrication system

- 69. Roger C. Montepio Oil Coolers. Lubrication system be able to dissipate more heat from their oil than normal airflow can accomplish Oil Temperature Regulator used to prevent the oil temperature from rising too high in hot weather, and to assist in raising the temperature during cold starts in winter weather The regulator makes use of the liquid in the cooling system provides a more positive means of controlling oil temperature than does cooling by radiation of heat from the oil pan wells.

- 70. Roger C. Montepio Lubrication system Oil Temperature Regulator made up of a core and a housing The core through which the oil circulates is of cellular or bellows construction, built to expose as much oil as possible to the coolant that circulates through the housing attached to the engine so that the oil will flow through the regulator after passing through the pump

- 71. Roger C. Montepio Oil Cooler consist of a radiator through which air is circulated by movement of the vehicle, or by a cooling fan Oil from the engine is circulated through this radiator and back to the sump or supply tank Lubrication system

- 72. Roger C. Montepio Lubrication system

- 73. Roger C. Montepio Oil Level Indicator The oil level indicator is usually of a bayonet type consists of a small rod, known as a dipstick, that extends through a tube into the crankcase It is marked to show when the crankcase is full or, if it is low, how much oil is needed Lubrication system

- 74. Roger C. Montepio Lubrication system Pressure Regulator

- 75. Roger C. Montepio Pressure Regulator The oil pump will produce pressures in great excess to those necessary This excess pressure, if uncontrolled, would cause excess oil consumption due to flooded cylinder walls and leakage through oil seals spring-loaded regulator valve is installed in the lubrication system to control pump pressure Lubrication system

- 76. Roger C. Montepio Lubrication system Types of Lubrication Systems a. Splash System no longer used in automotive engines, it is used in small equipment engines Operation dippers on the connecting rods enter oil in the crankcase with each crankshaft revolution, thus splashing the oil.

- 77. Roger C. Montepio Lubrication system Types of Lubrication Systems b.Combination Splash and ForceFeed System oil is delivered to some parts by means of splash and to other parts through oil passages, under pressure from a pump in the crankcase The main and the camshaft bearings are usually the items that are force fed while the connecting rods are fitted with dippers that supply oil to the rest of the engine by splash

- 78. Roger C. Montepio Lubrication system Types of Lubrication Systems c. ForceFeed Lubrication System more complete pressurization of lubrication oil is forced by the oil pump from the crankcase to the main bearings and the camshaft bearing

- 79. Roger C. Montepio Lubrication system Types of Lubrication Systems all of the bearings are lubricated by oil under pressure includes main bearings, rod bearings, camshaft bearings, and the complete valve provides lubrication under pressure to the pistons d.Full ForceFeed Lubrication System

- 80. Roger C. Montepio Cooling system Cooling medium (1)Liquid is the most popular coolant in automotive use cooling system provides the most positive cooling best for maintaining uneven engine temperature (2) Air most practical for small vehicles and equipment because no radiator or hoses are required do not run at even temperatures and require extensive use of aluminum to dissipate heat.

- 81. Roger C. Montepio Cooling system other sources of heat dissipation for the engine in addition to the cooling system (1) The exhaust system dissipates as such, if not more, heat than the cooling system, although that is not its purpose (2) The engine oil, removes heat from the engine and dissipates it to the air from the sump (3) The fuel provides some engine cooling through vaporization (4) A measurable amount of heat is dissipated to the air through radiation from the engine.

- 82. Roger C. Montepio Types of cooling system Cooling system Air Cooling system Use air as a cooling medium Cooling effect is produced by means of fins or projections on the walls of the cylinder Common examples of air-cooled engine airplane Motorcycle Lawn mower, garden tractor Small and medium diesel tractor

- 83. Roger C. Montepio Cooling system Types of cooling system Advantages Lighter in weight Simpler in construction More convenient and less trouble No danger of freezing in cold weather Disadvantage Difficult to maintain proper cooling under all conditions impossible to fully control cylinder temperature Usually run a little hotter than water cooled engine

- 84. Roger C. Montepio Cooling system Types of cooling system Liquid Cooling system Use liquid as a cooling medium use in all types of engine Advantages Plentiful and available anywhere absorbs heat well Circulates freely at all temperature between freezing to boiling No danger

- 85. Roger C. Montepio Cooling system Types of cooling system Liquid Cooling Systems