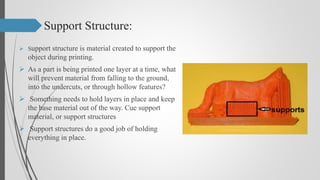

This document summarizes a process for efficiently generating support structures for 3D printing. It introduces an optimization framework that minimizes the amount of support structures needed by 3D printers. The framework first orients the input model to reduce overhanging areas, then detects overhang points requiring support. It builds tree-like support structures from these points instead of column structures, merging branches to reduce length. This approach significantly cuts the amount of support material used and decreases printing time by an average of 29.4% compared to other software solutions.