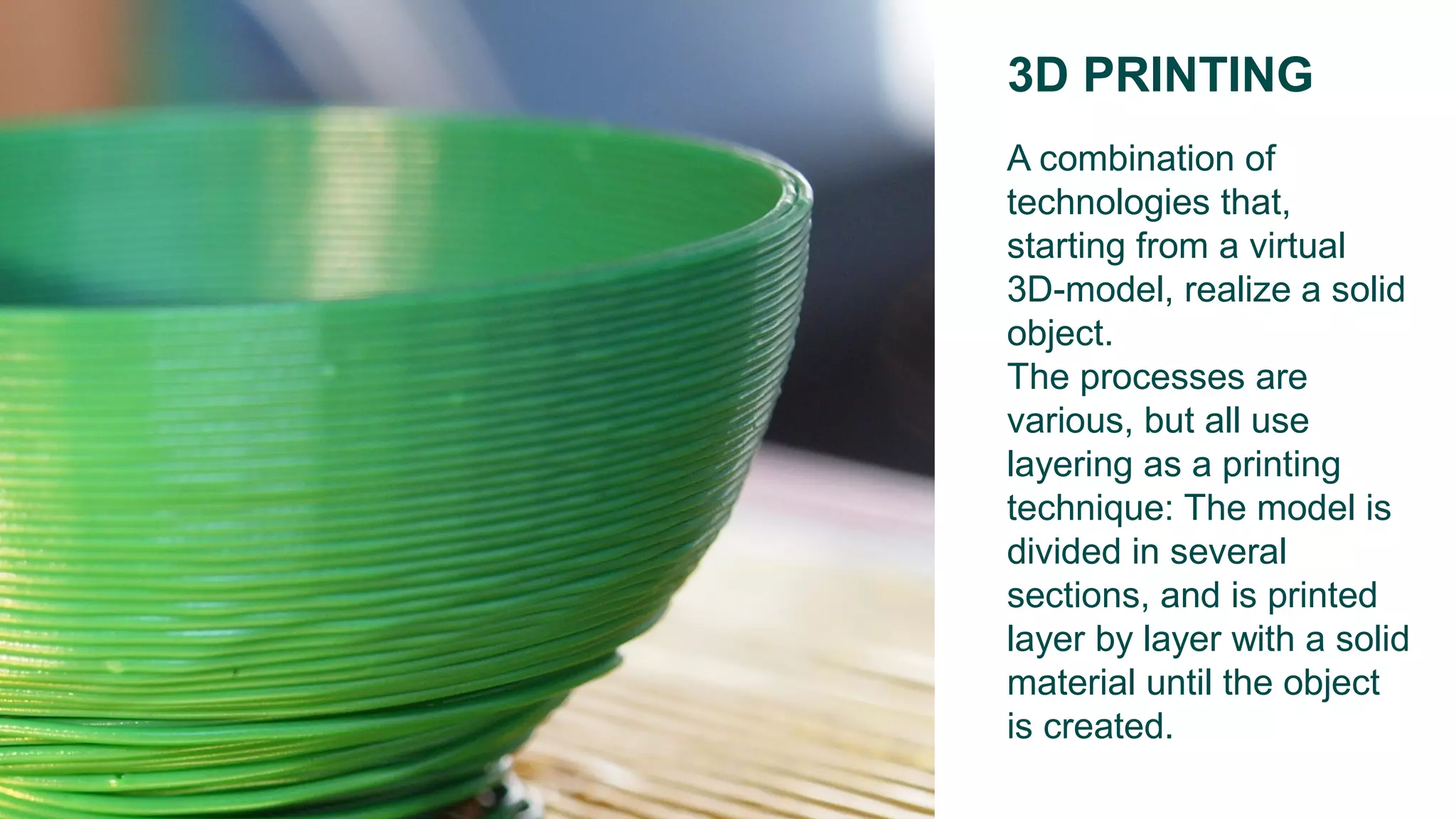

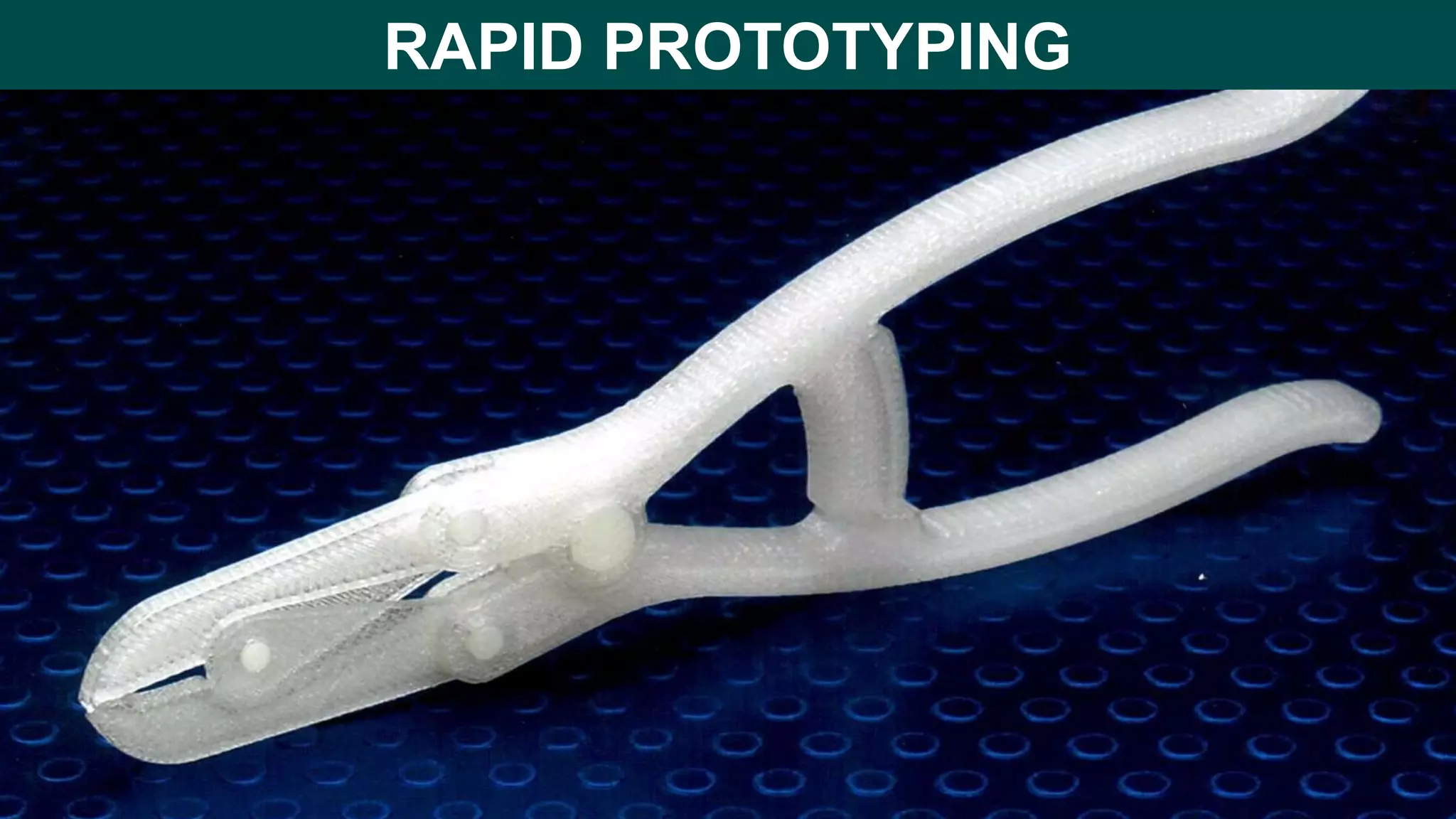

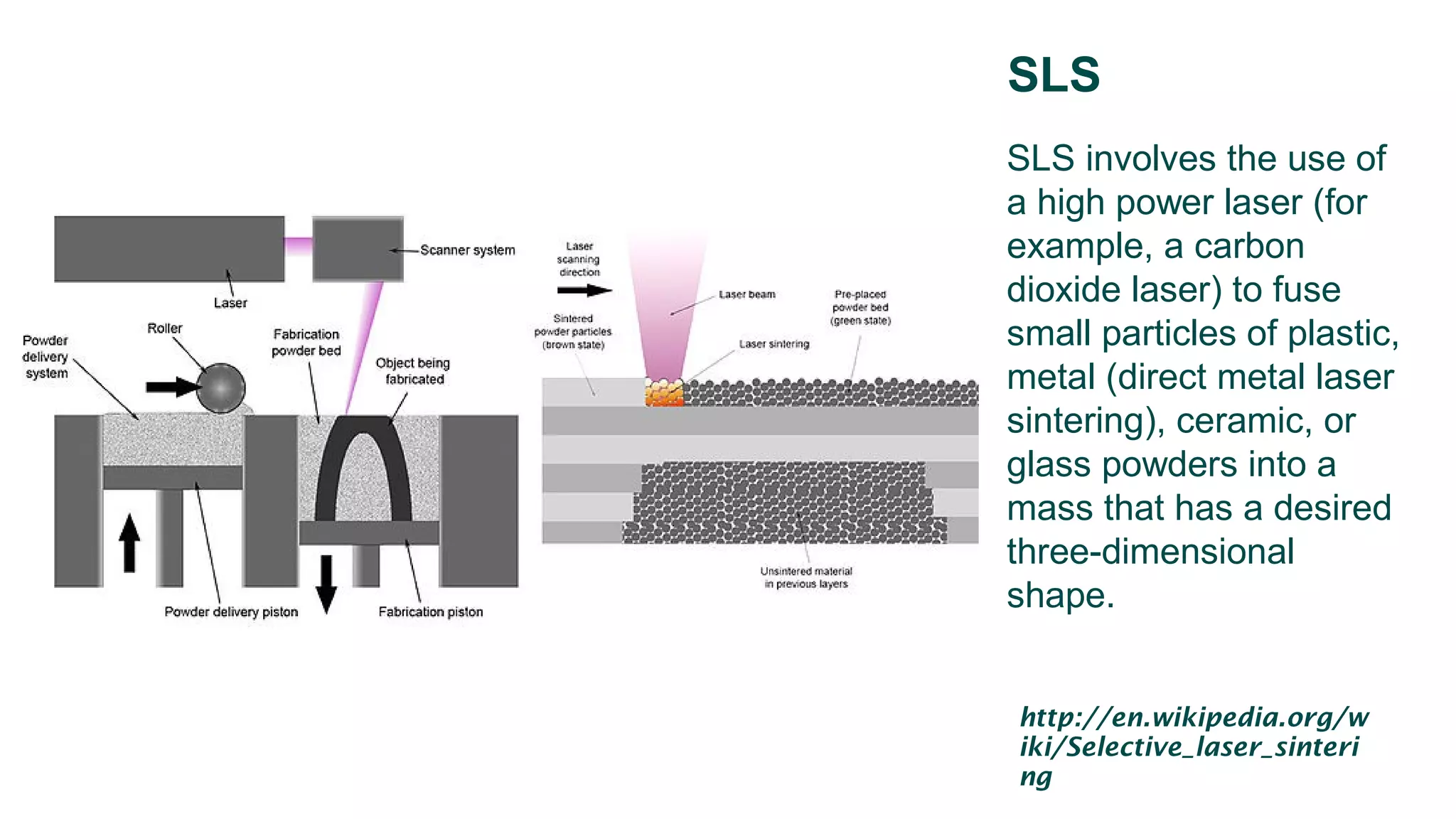

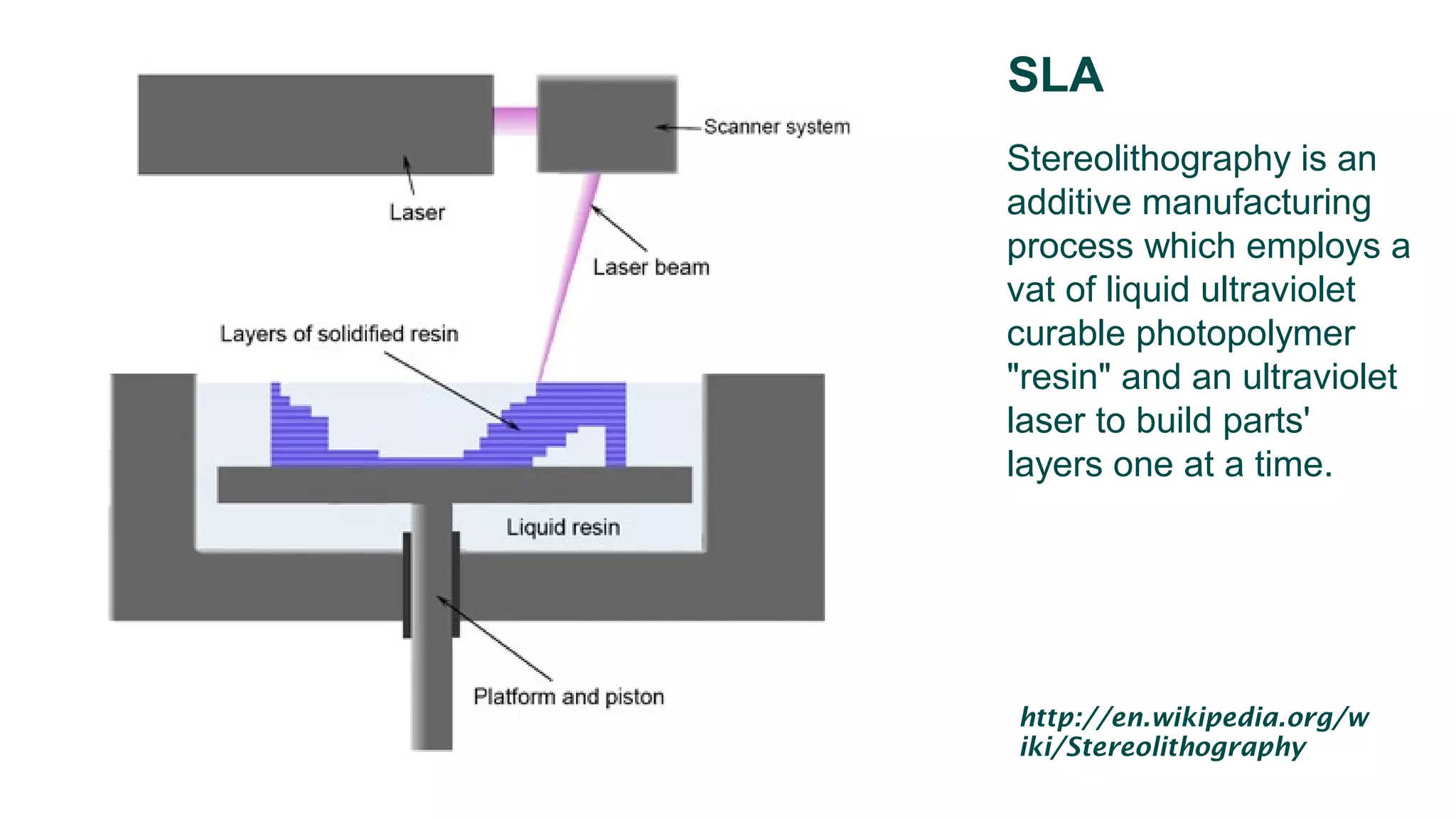

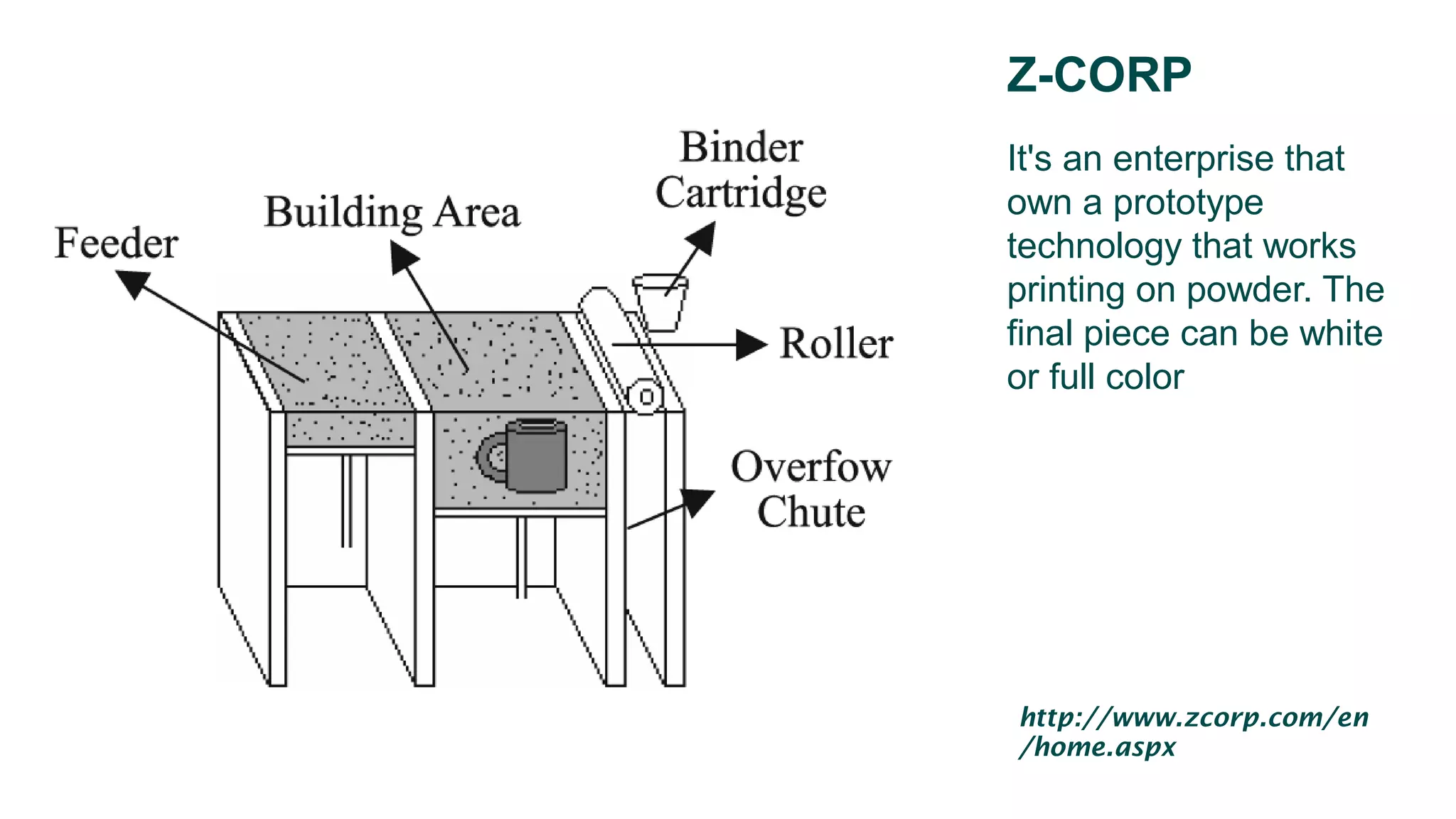

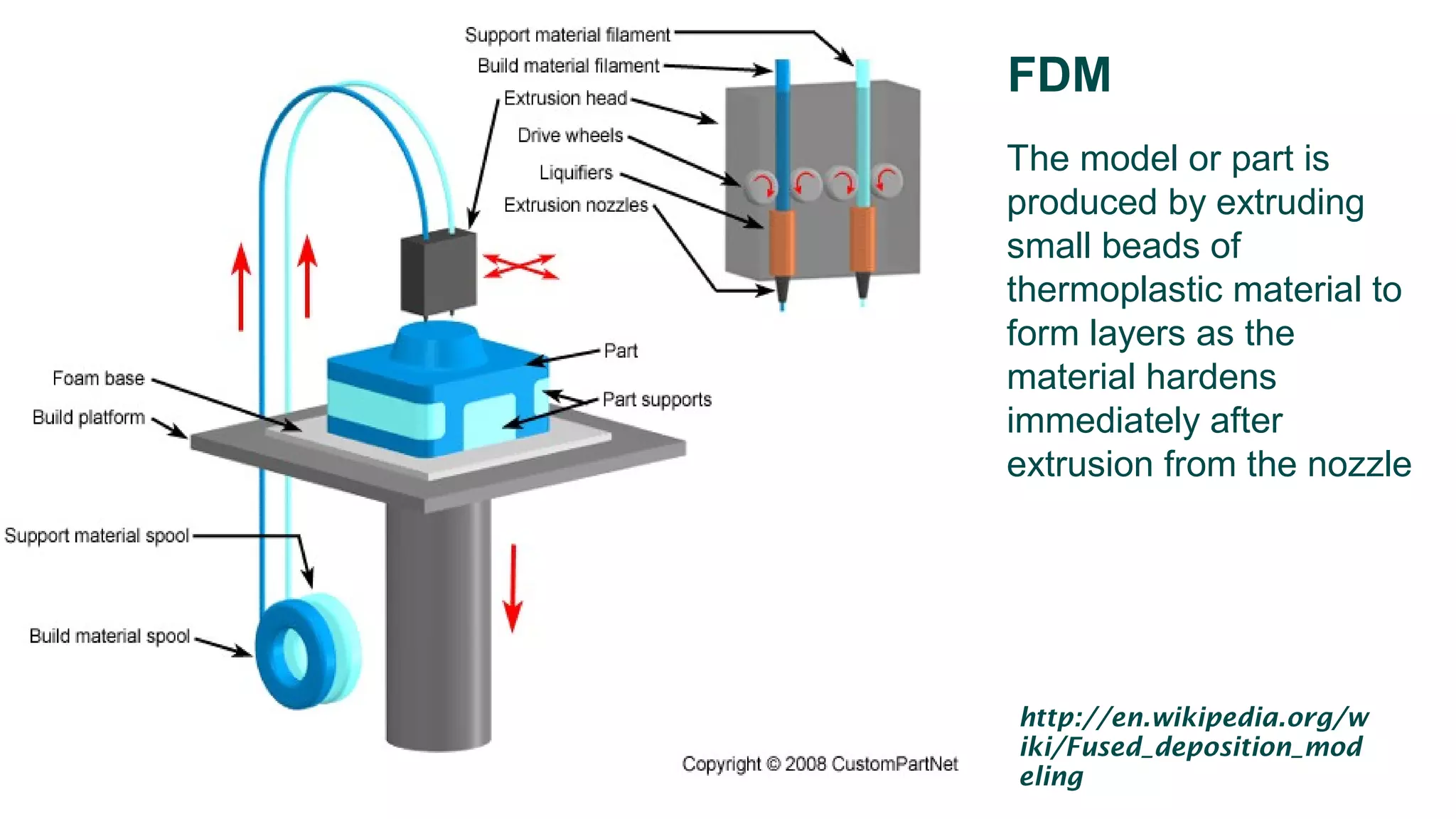

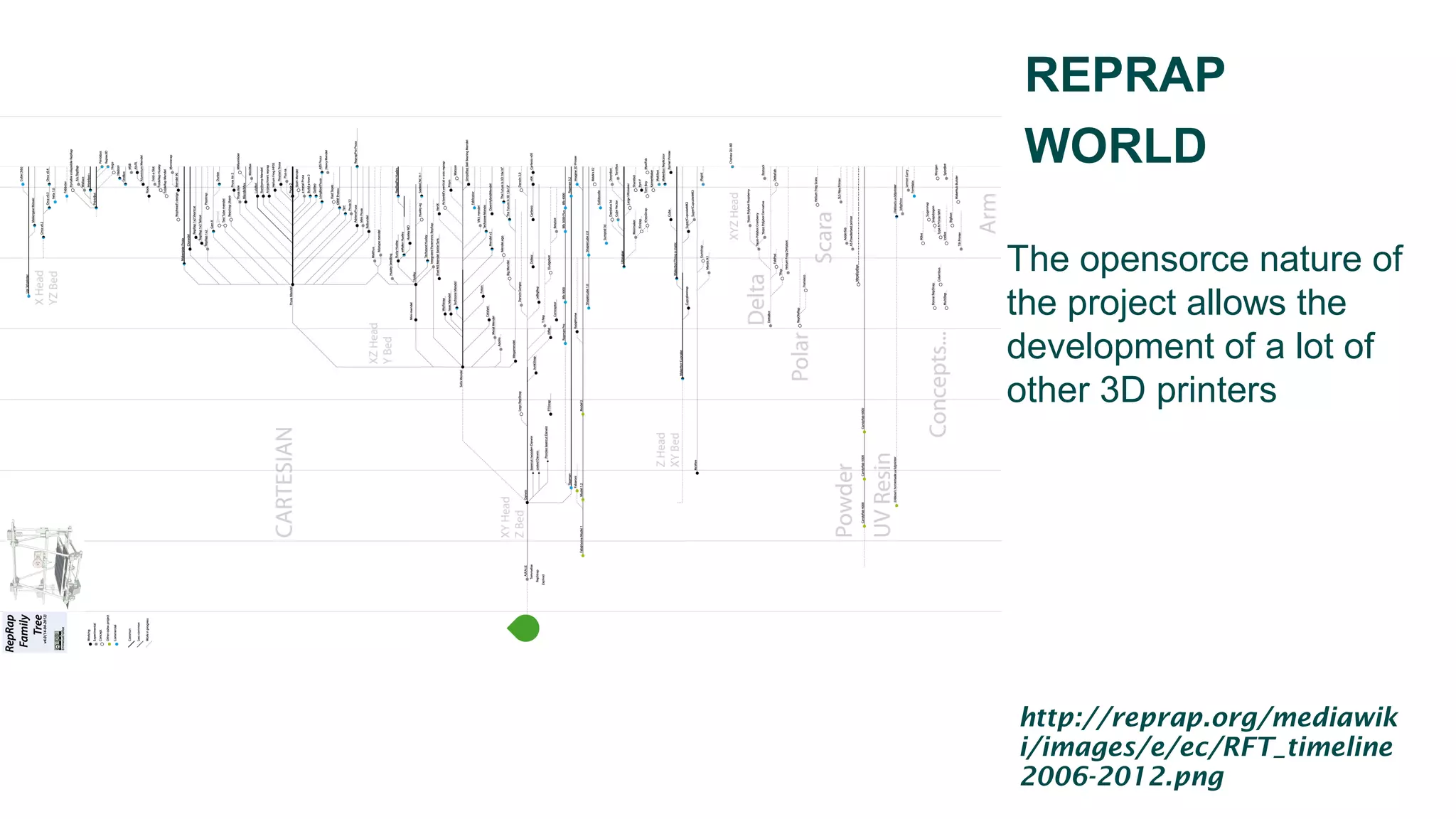

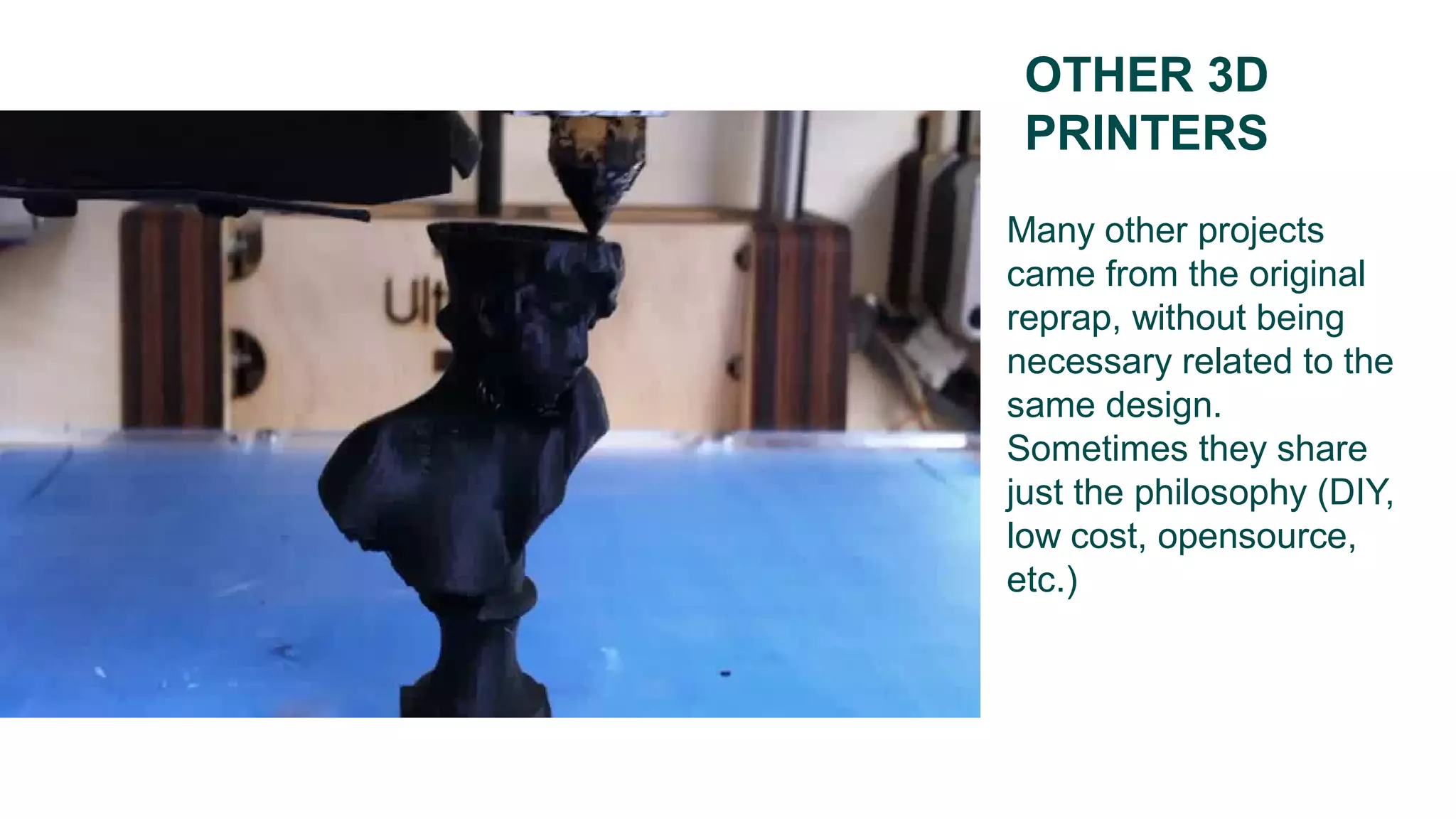

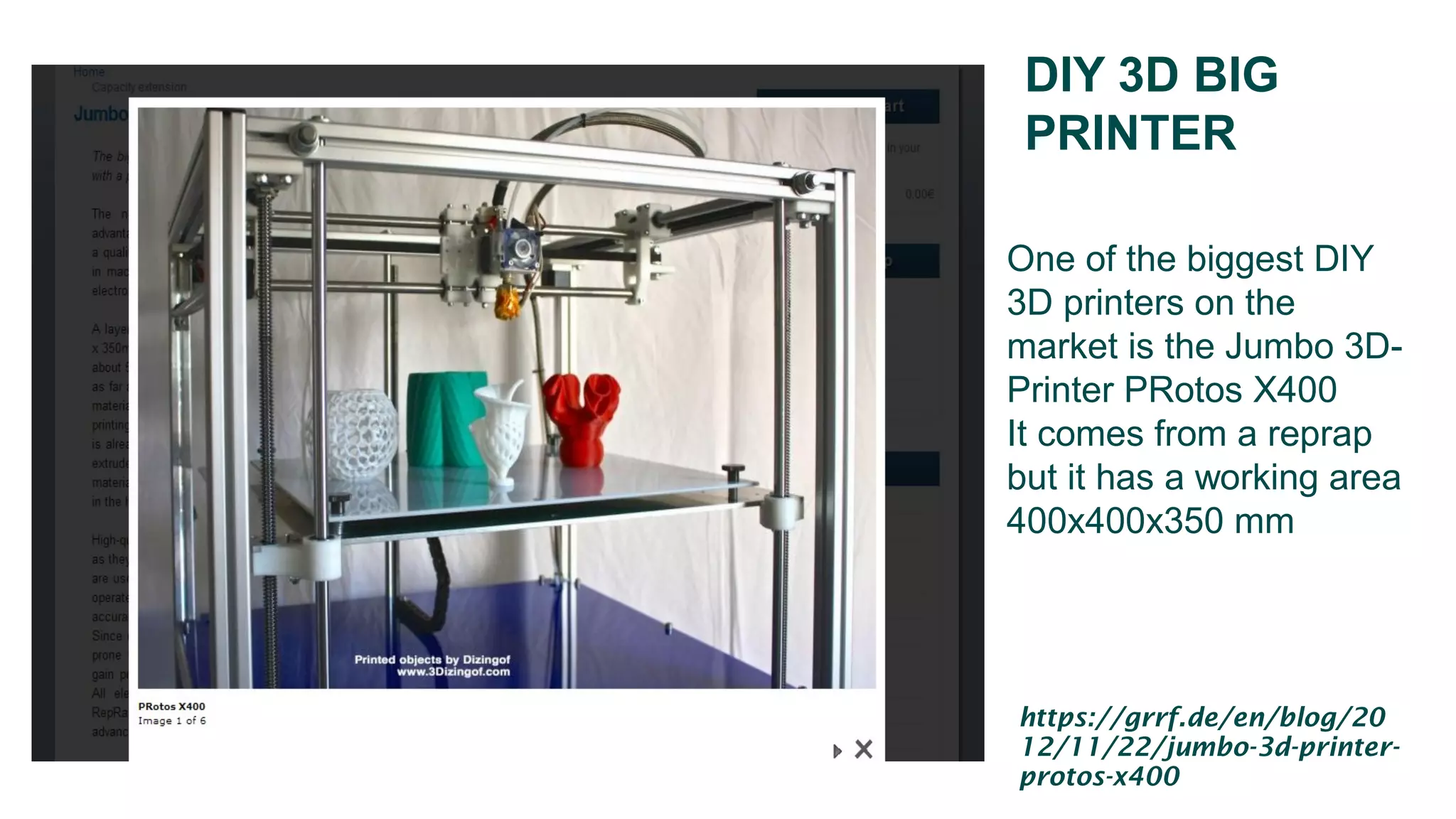

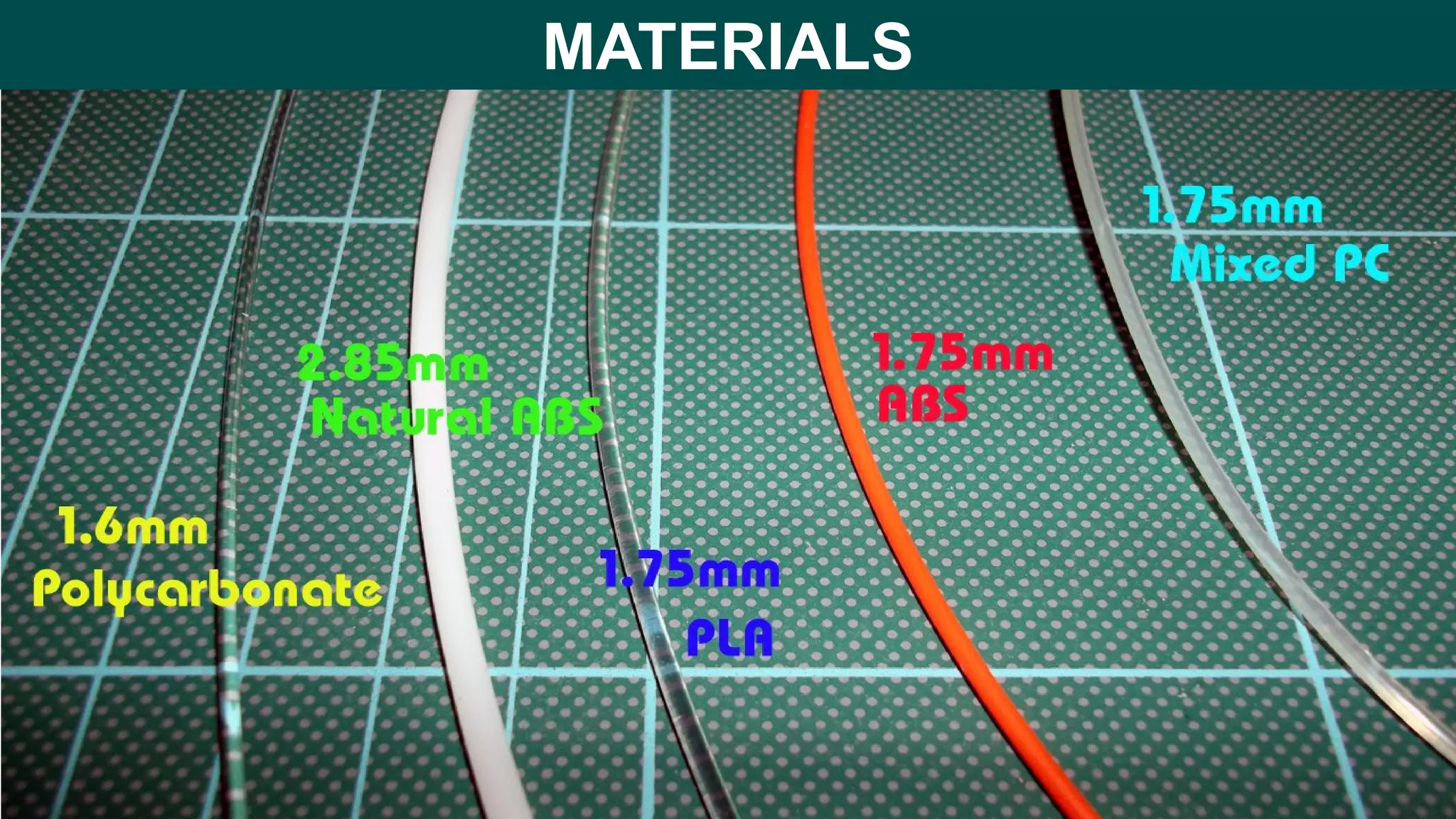

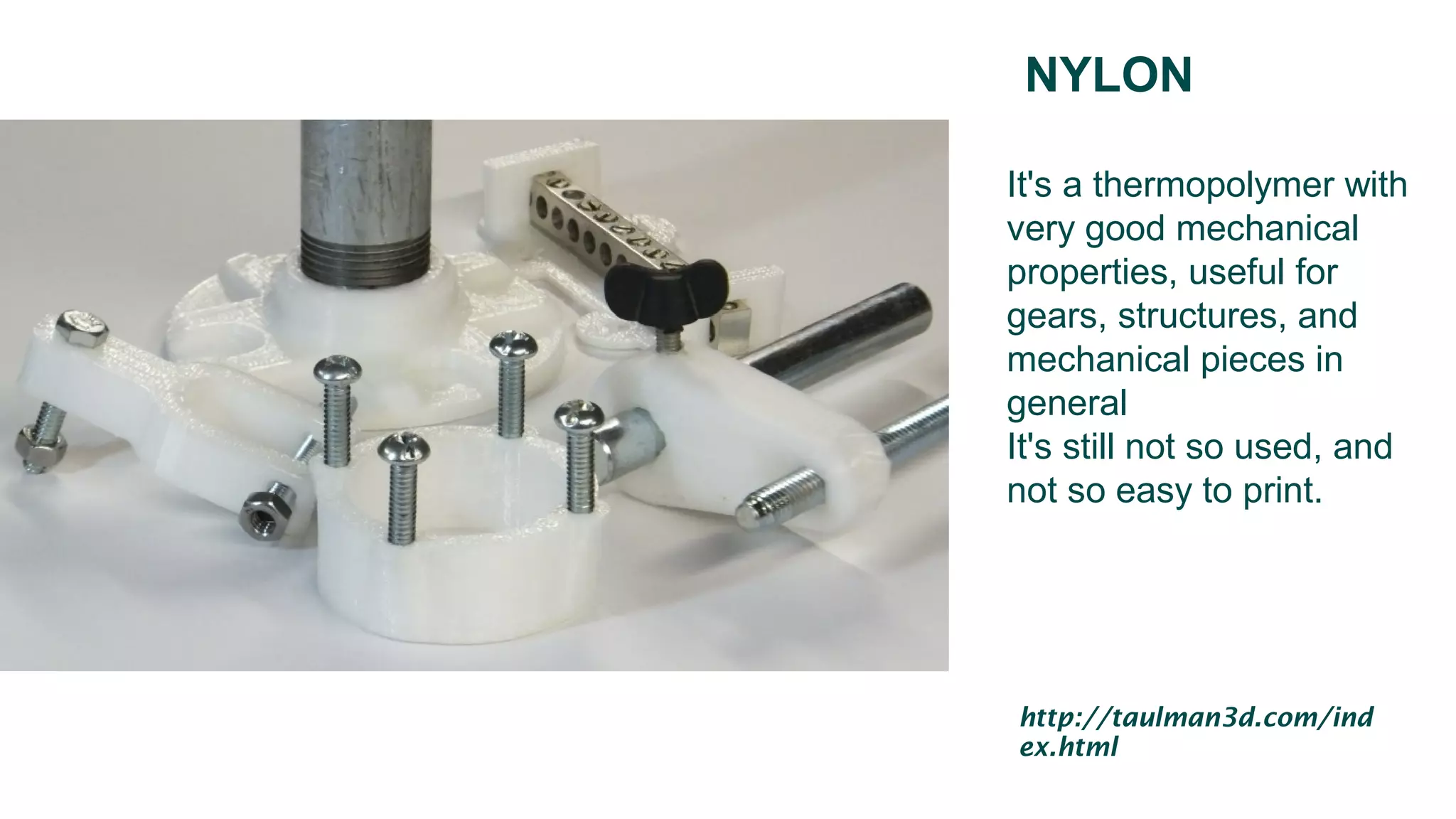

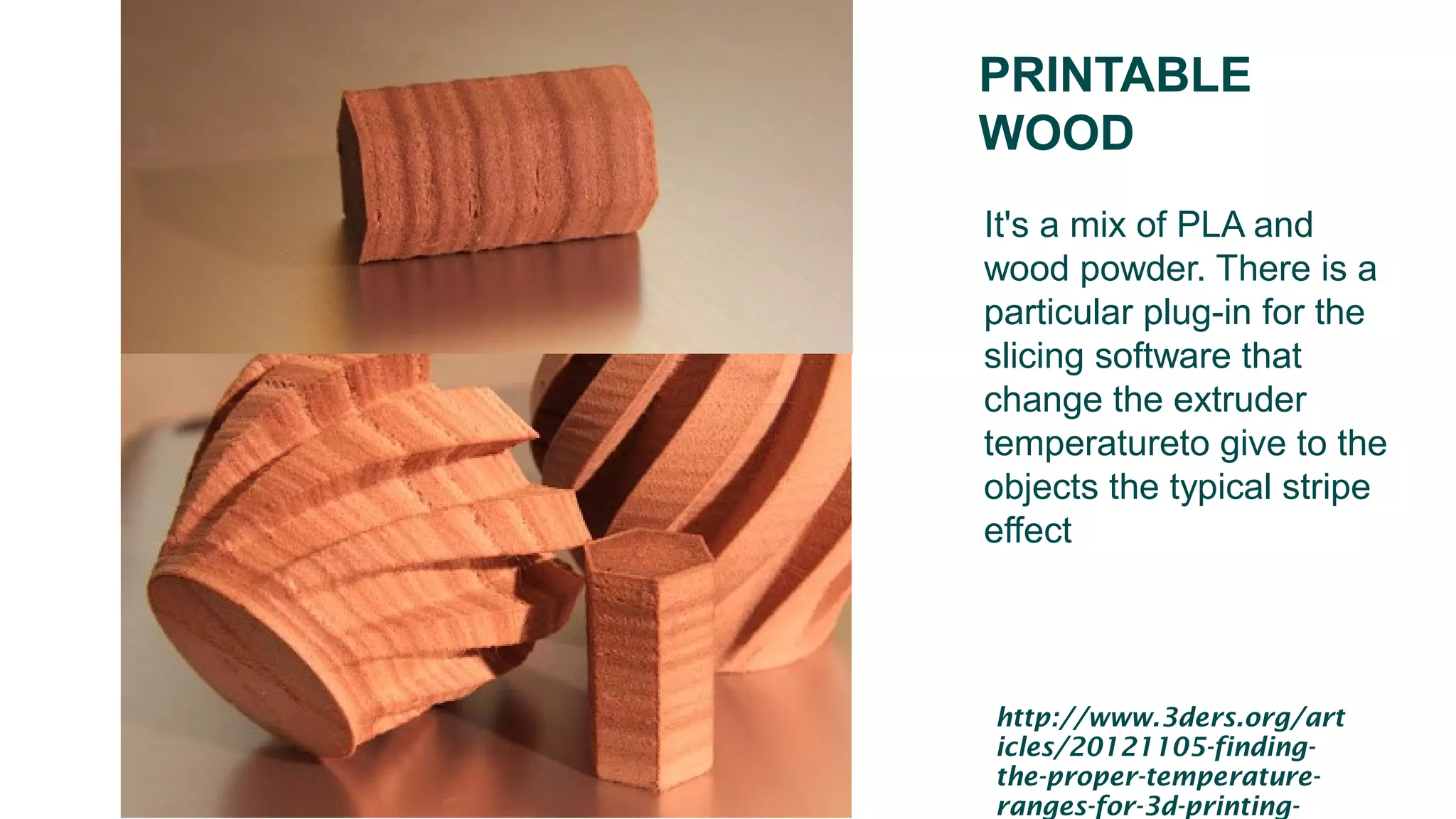

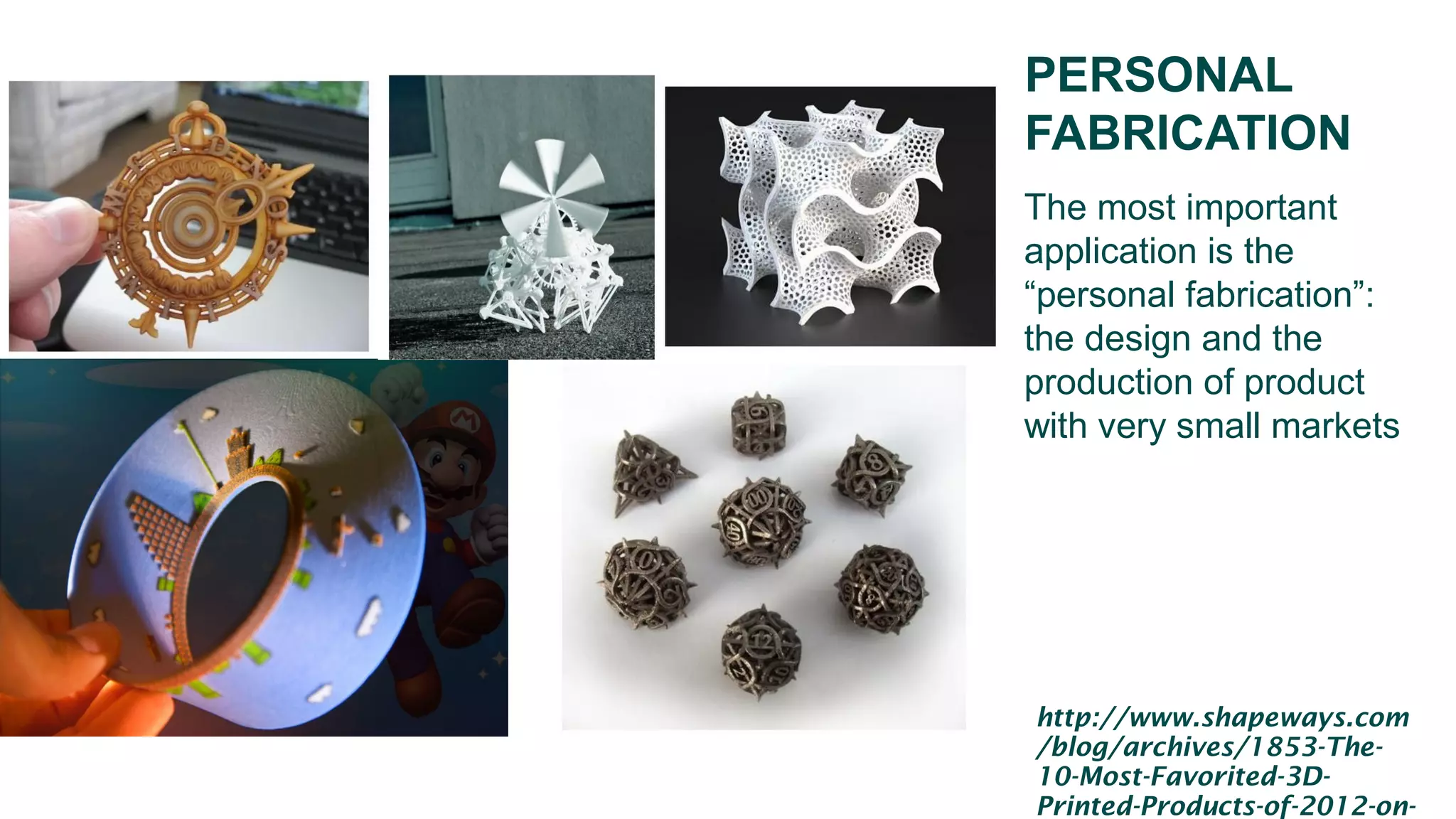

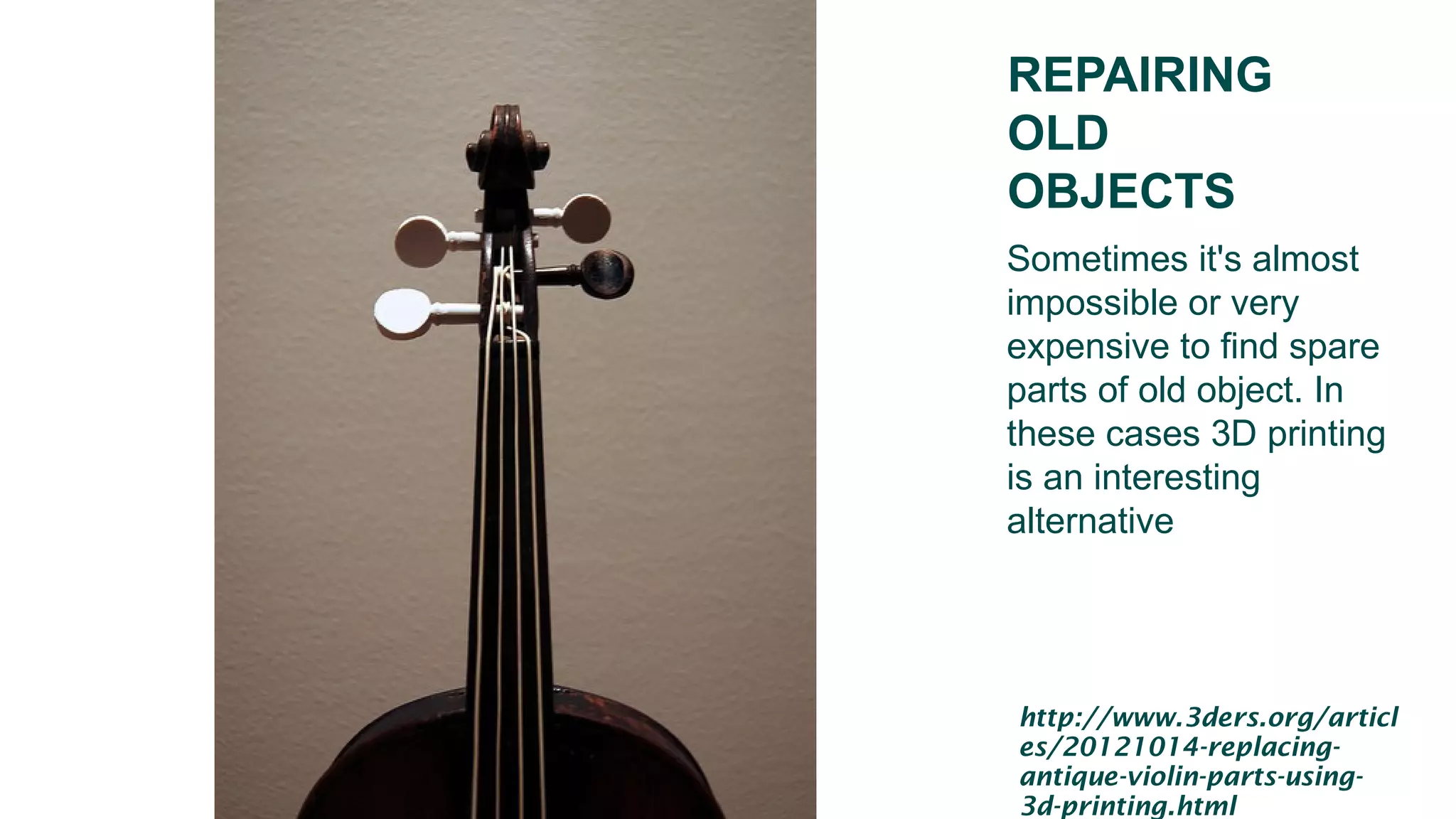

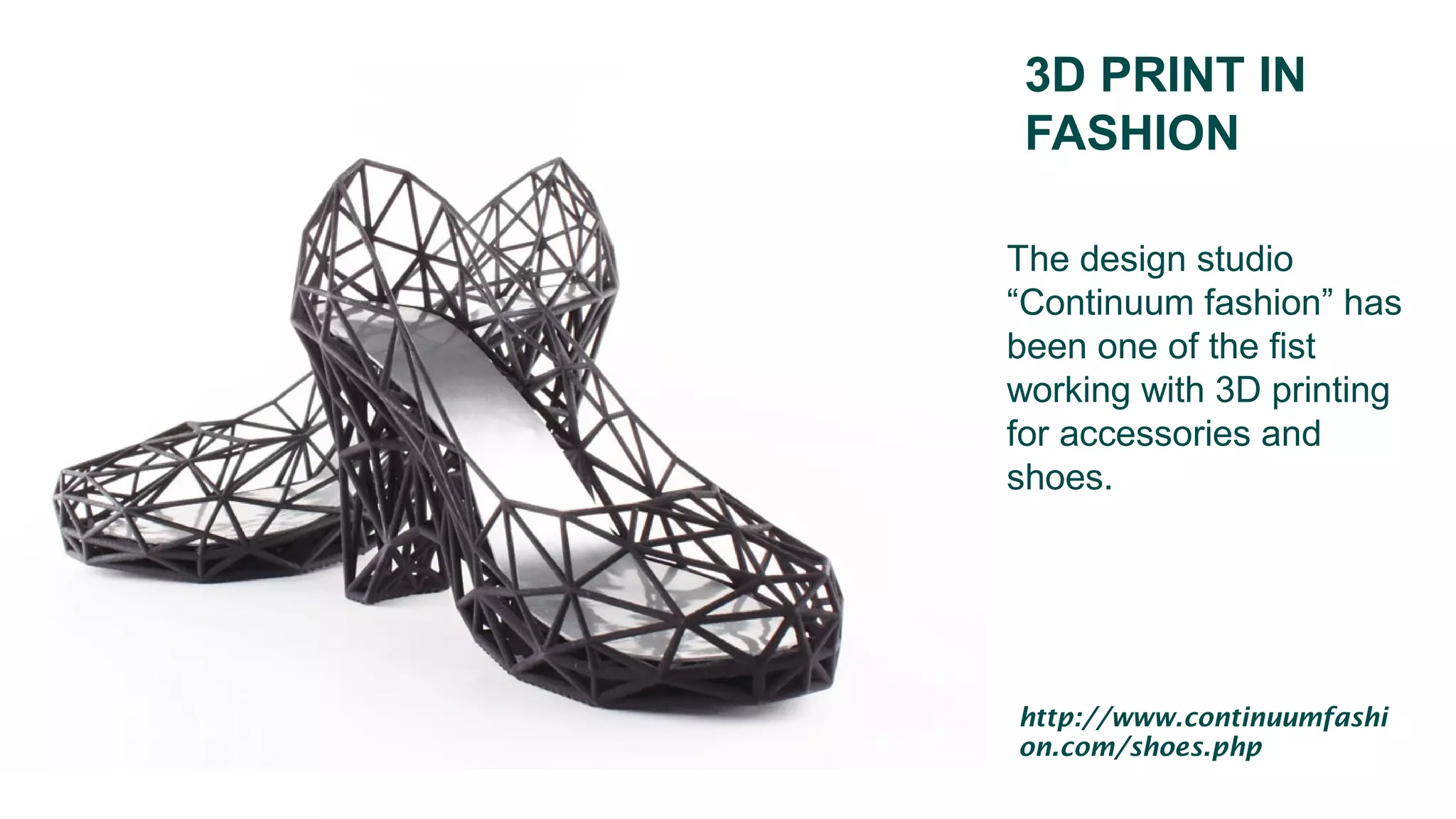

La stampa 3D è una tecnologia che consente di creare oggetti solidi a partire da modelli virtuali, utilizzando diverse tecniche di stratificazione. Tra le metodologie citate ci sono la sinterizzazione laser selettiva (SLS) e la stereolitografia (SLA), mentre vari progetti open-source come RepRap hanno dato impulso a molteplici sviluppi nel campo. Le applicazioni spaziano dalla fabbricazione personale a protesi mediche, con materiali comuni come ABS e PLA utilizzati nella produzione di oggetti di diverse forme e funzionalità.