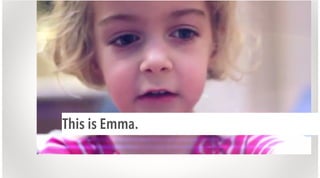

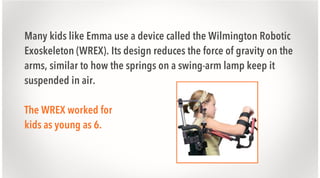

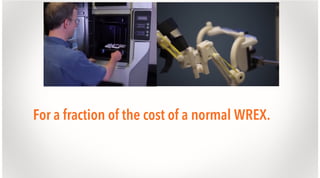

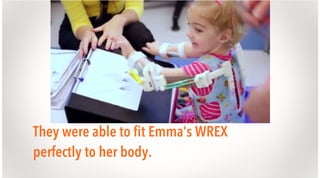

3D printing allows for customized devices like Emma's robotic exoskeleton. Emma has a condition preventing her from lifting her arms. Researchers 3D printed a miniature exoskeleton specifically for her small size and growing body at a fraction of the usual cost, letting her color and paint for the first time. 3D printing is revolutionizing manufacturing by making customized designs easily accessible to individuals.