This document discusses the use of magnetron sputtering to deposit thin film layers for solar cell applications. Some key points:

- Magnetron sputtering is widely used for vacuum thin film deposition and can coat a wide range of materials. It is used to deposit the various layers of thin film solar cells.

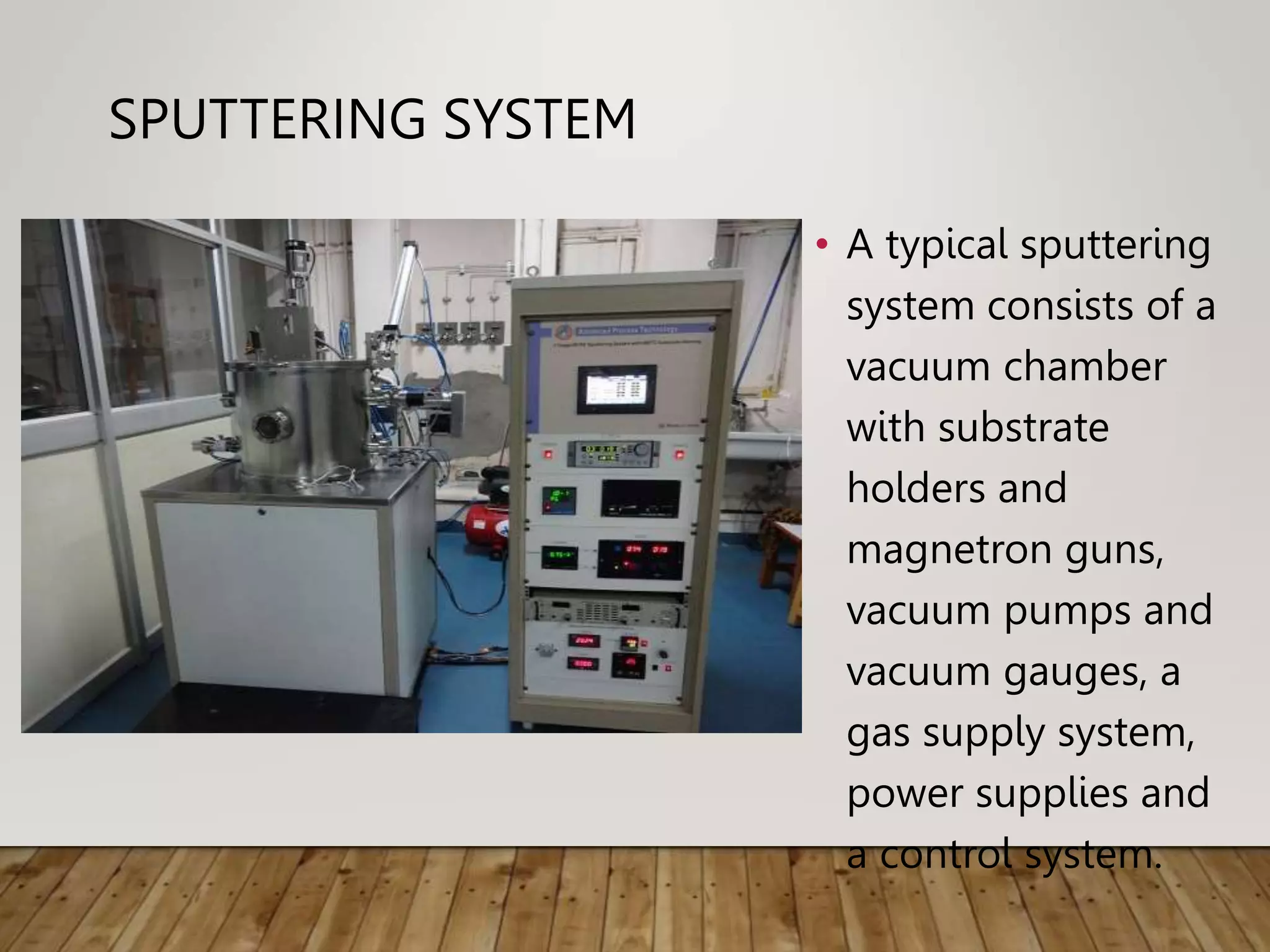

- A typical sputtering system consists of a vacuum chamber, magnetron guns, vacuum pumps and power supplies. Magnetrons confine plasma in front of the target during sputtering.

- Parameters like power, pressure and temperature can be controlled to deposit thin film layers with the desired properties. Insulating materials require RF power.

- Thin film solar cells use multiple thin layers, including a sem