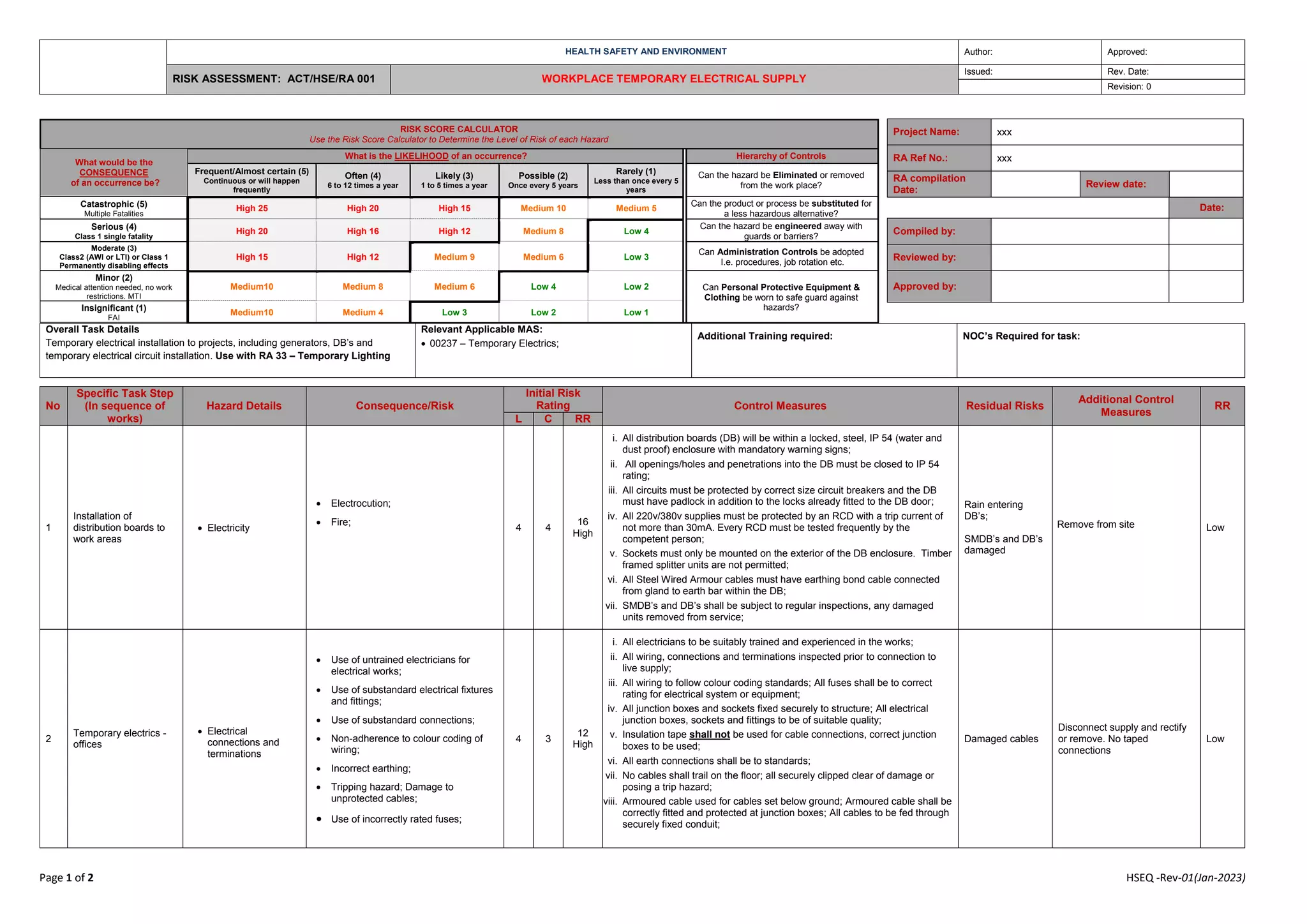

The document outlines a risk assessment for temporary electrical installations at a workplace, focusing on hazards such as electrocution, fire, and equipment failures. It details the initial risk ratings, control measures, and additional assessments necessary to ensure safety during operations involving distribution boards, temporary electrical works, and site generators. The risk assessment emphasizes the importance of using trained electricians, following proper installation practices, and maintaining equipment to mitigate risks.