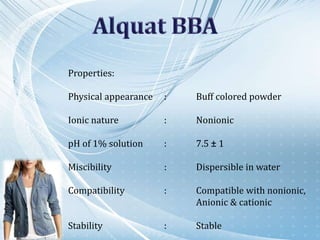

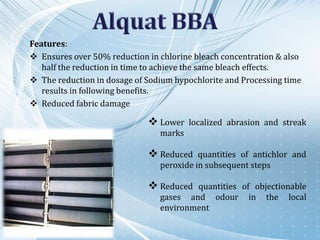

Bleach Bath Accelerator is a unique catalyst and desorbing agent designed to greatly accelerate the action of chlorine bleach on indigo. It allows for substantial reductions in chlorine bleach concentrations, bleach cycle time, and process temperatures while achieving the same shade. Key benefits include reduced fabric damage, improved productivity through shorter cycle times, lower environmental impact through reduced effluent, and reduced costs through lower temperatures and chemical use. It is especially useful for bleaching tencel blends, reducing damage and fibrillation compared to sodium hypochlorite alone.