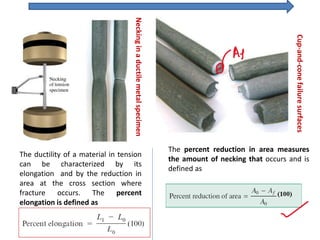

The document discusses the mechanical properties of materials through stress-strain curves, highlighting terms such as nominal stress, true stress, proportional limit, and yield points. It also explains the differences between ductile and brittle materials, including their behaviors during tensile tests and the significance of parameters like Young's modulus and Poisson's ratio. Additionally, it presents related definitions and typical stress-strain diagrams for both ductile and brittle materials.