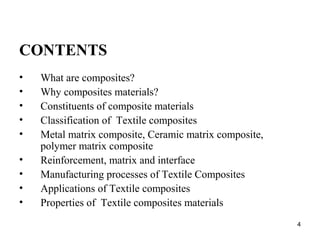

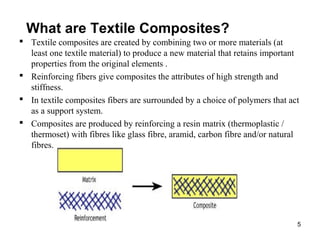

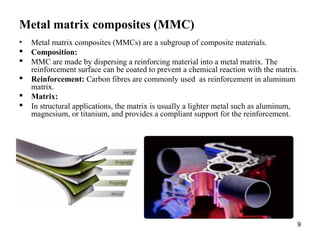

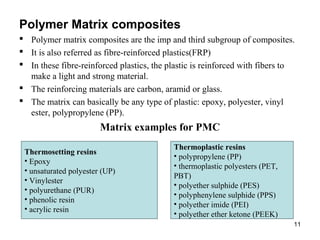

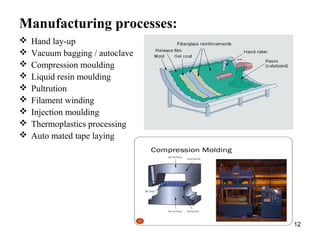

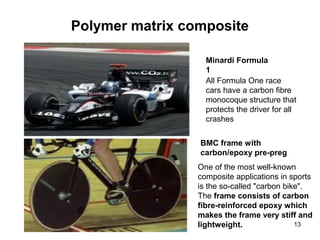

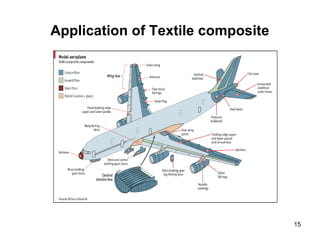

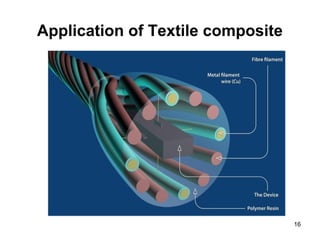

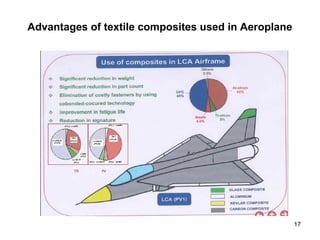

This presentation discusses textile composites. It begins with an introduction of the presenter and the department. The topic is then introduced as textile composites. The contents section outlines what will be covered, including definitions of composites, why they are used, constituents, classifications, manufacturing processes, applications, and properties. Composites are defined as combining two materials where one is usually a textile to produce a new material. They are preferred due to properties like strength, weight, and design flexibility. Composites are classified by their matrix as metal, ceramic, or polymer. Manufacturing processes include hand layup, molding, and filament winding. Applications include aerospace, automotive, sports equipment, and more