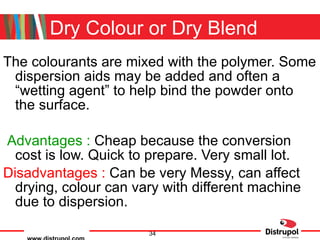

There are several methods for colouring polymers, each with advantages and disadvantages. Dry colour involves mixing pigments directly into the polymer but can be messy and inconsistent. Masterbatch uses a high concentration of pigments compounded with a carrier polymer for better dispersion. Liquid colour is similar but uses a liquid carrier. Fully compounded colour extrudes the pigments with the base polymer for the most accurate and controlled colours. The appropriate colouring method depends on factors like required colour consistency, flexibility, and impact on material properties.