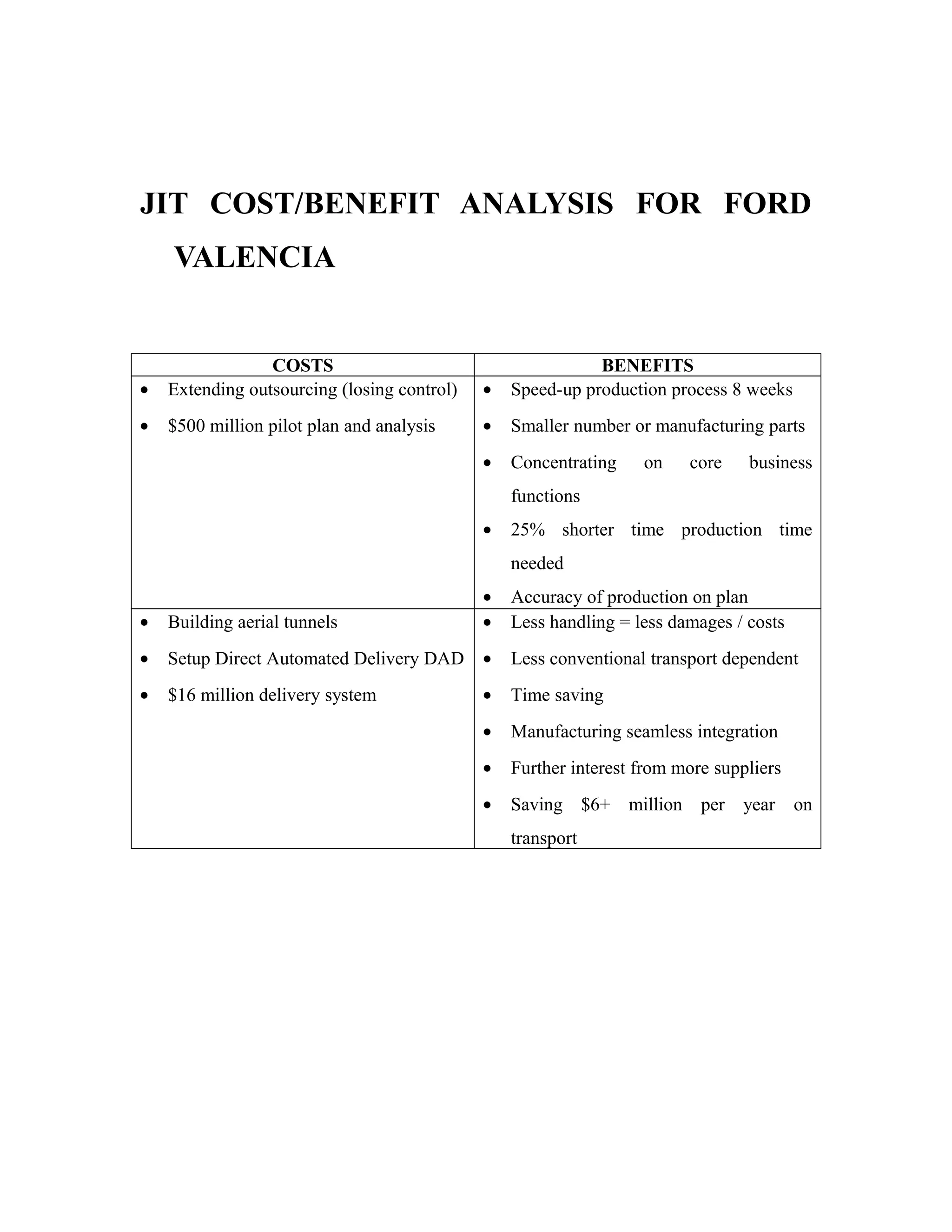

Just-in-time (JIT) manufacturing aims to eliminate waste by producing the right goods, in the right quantities, at the right time. This minimizes inventory and improves efficiency. JIT was developed in Japan in the 1970s at Toyota and focuses on continuous improvement. It requires close coordination between all parts of the production process and supply chain. While very effective, JIT provides less buffering against disruptions and requires more stable demand than traditional approaches.