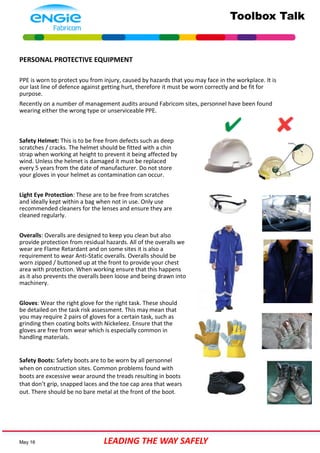

PPE is worn to protect workers from workplace hazards and must be worn correctly and be fit for the intended purpose. Recent audits found workers wearing the wrong or unserviceable PPE. The correct PPE includes safety helmets that are less than 5 years old without cracks or deep scratches, light eye protection without scratches kept clean in a bag when not in use, flame retardant and possibly anti-static overalls worn zipped up, gloves appropriate for the task without excessive wear, and safety boots with intact treads and toe caps without bare metal showing through.