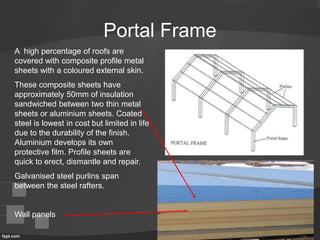

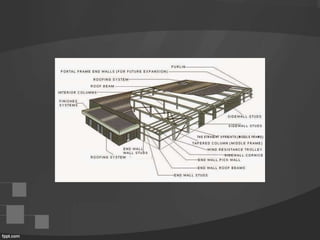

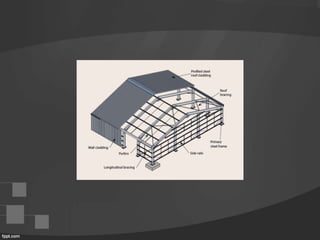

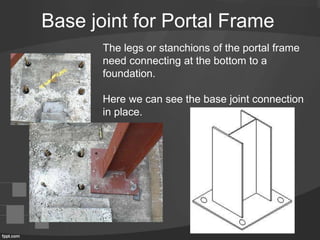

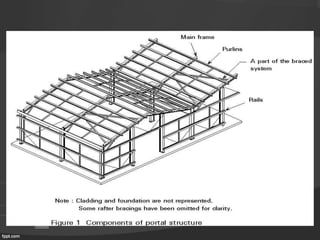

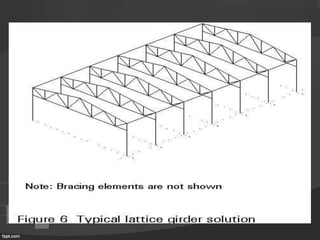

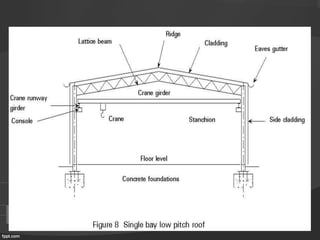

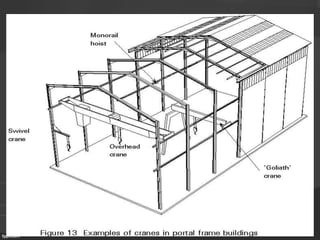

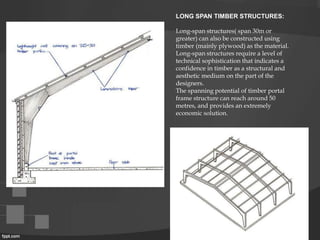

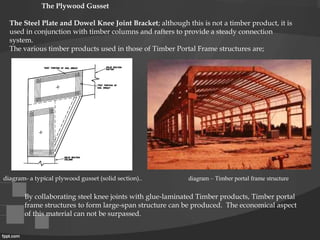

Portal frames are single storey steel structures that provide large open floor plans. They consist of vertical columns connected by horizontal beams and rafters to form the frame, without interior columns. This allows for unobstructed floor spaces useful for industrial, warehouse and commercial buildings. Portal frames can be made of steel, concrete or timber, with steel being most common due to its strength, light weight and ease of construction.