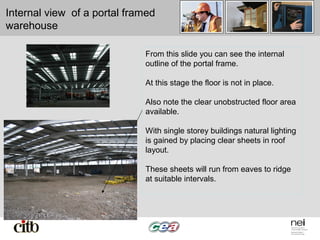

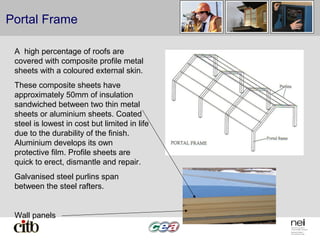

Portal frames are steel structures without interior columns, allowing large open floorplans. They are commonly used for single-story buildings like factories, warehouses, and shopping centers that require unobstructed floor space. Portal frames have advantages like fast construction and ease of assembly, but disadvantages like susceptibility to fire damage and corrosion.