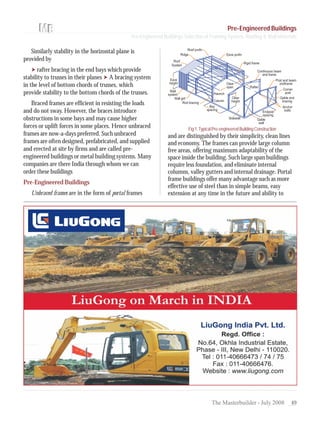

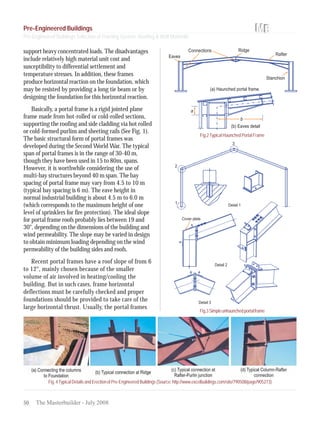

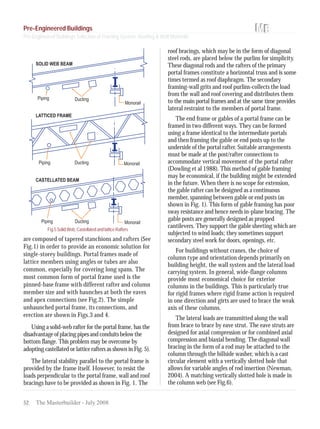

This document discusses the selection of framing systems and roof/wall materials for pre-engineered industrial buildings. It describes two main framing systems - braced frames and unbraced frames. Unbraced portal frames are now more commonly used as they provide large column-free spaces and are simpler and more economical. Portal frames typically have spans of 30-40m and use tapered columns and rafters. Roof bracing and wall bracing are needed to resist loads perpendicular to the frame. The document provides details on frame configurations, connections, and considerations in choosing framing and cladding materials.