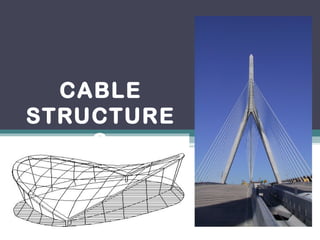

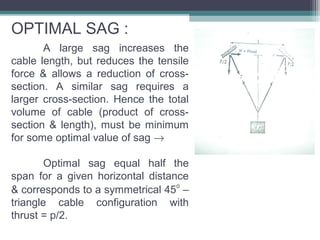

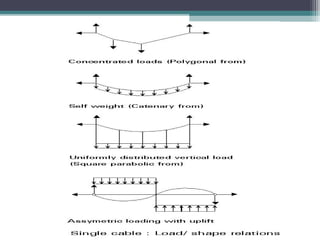

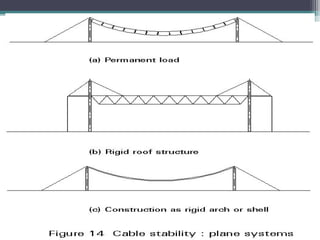

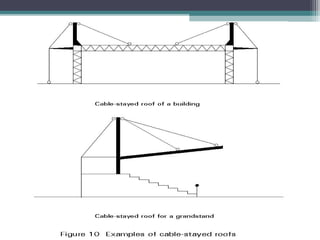

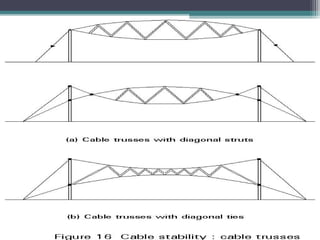

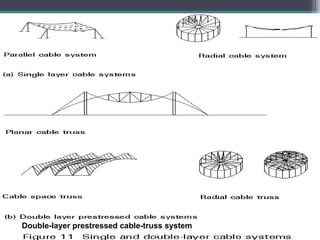

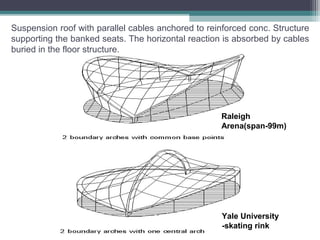

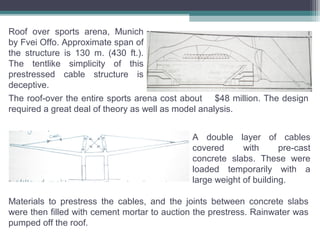

The document discusses cable structures and their role as form-active systems that transmit loads through tension and compression. It highlights the design considerations, advantages, and limitations of cable systems, including their adaptability to loads, stability issues, and applications in modern architecture such as sports arenas and bridges. The importance of materials, particularly steel, and structural elements in optimizing cable systems for large spans is also emphasized.