02 patterns

•Download as PPT, PDF•

0 likes•73 views

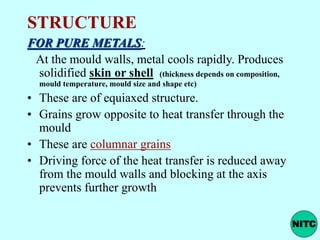

The document discusses the structure and solidification of pure metals and alloys during casting. It provides information on: 1. The formation of equiaxed and columnar grains near mould walls during solidification for pure metals. 2. Alloys solidify over a range of temperatures, forming a mushy state within this temperature range. 3. The size and distribution of grains throughout a casting depends on the rate and direction of heat flow during solidification. 4. Shrinkage and porosity occur during solidification as metals contract, which can lead to dimensional changes and cracking in castings.

Report

Share

Report

Share

Recommended

Ceramics

Properties of ceramics; Classification of ceramics; Ceramic raw material; Fabricating and processing of ceramic;Application of Ceramics; Glasses; Clay Products; Structural clay product; Whitewares; Refractories: Fireclay; Silica; Basic refractories; Special refractories; Abrasives; Cements; Advanced Ceramics

MANUFACTURING SCIENCE S5ME -NITC-2016

The document discusses the key steps in the sand casting process:

1. Creating a mechanical drawing and pattern of the part to be cast

2. Preparing molds by setting cores and positioning patterns

3. Pouring molten metal and allowing it to solidify in the mold

4. Removing the casting and performing trimming and finishing operations

The document provides an overview of the sand casting process from pattern making to final inspection and packaging for shipment.

Ch2 foundaryproc Erdi Karaçal Mechanical Engineer University of Gaziantep

This document provides an overview of foundry processes. It discusses how molds are made by preparing sand and pouring molten metal into prepared molds. Key steps include making molds and cores, melting and pouring metals, and allowing the casting to solidify. Molds are prepared using patterns and sand, and may use cores to create internal cavities. The document outlines important mold characteristics and different types of molds, cores, and sand used in the casting process.

metal_casting

There are two main categories of metal casting processes: expendable mold processes where the mold is destroyed to remove the part, and permanent mold processes where the metal mold can be reused. Sand casting is the most widely used casting process, accounting for the majority of total tonnage cast, and allows for casting of nearly all alloys. It involves making a sand mold by packing sand around a pattern, then pouring molten metal and allowing it to solidify before breaking apart the mold to remove the casting.

12.casting of metals

Metal casting is a manufacturing process where liquid metal is poured into a mold and solidifies. Sand casting is a common type of metal casting that uses sand as the mold material. Key steps in sand casting include pattern making, molding, melting and pouring the metal, solidification, and cleaning. Sand provides advantages as a mold material such as low cost, high temperature stability, and permeability. Shell molding is an alternative casting method that uses a resin-bonded sand mixture to form the mold around a pattern.

Ceramics1

Ceramics are inorganic, non-metallic materials processed at high temperatures. They are composed of clays, sand, and feldspar. The main types of ceramics are whitewares, refractories, glasses, abrasives, and cements. Ceramics have various applications including crockery, tiles, furnace bricks, glass containers, and armor protection. Advanced ceramics like silicon carbide are used in automotive and body armor components due to their heat resistance, wear resistance, and ballistic properties.

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Metal Casting Technologu

This document provides information about the Metal Casting Technology course offered at VIT University. It includes details about the course faculty, textbooks, evaluation methods, and modules. The first module introduces metal casting processes, foundry industry basics, casting principles, and moulding practices. It also defines important casting terminology and properties of moulding sand like permeability and refractory properties. Common moulding equipment, patterns, and gating systems are also summarized.

Recommended

Ceramics

Properties of ceramics; Classification of ceramics; Ceramic raw material; Fabricating and processing of ceramic;Application of Ceramics; Glasses; Clay Products; Structural clay product; Whitewares; Refractories: Fireclay; Silica; Basic refractories; Special refractories; Abrasives; Cements; Advanced Ceramics

MANUFACTURING SCIENCE S5ME -NITC-2016

The document discusses the key steps in the sand casting process:

1. Creating a mechanical drawing and pattern of the part to be cast

2. Preparing molds by setting cores and positioning patterns

3. Pouring molten metal and allowing it to solidify in the mold

4. Removing the casting and performing trimming and finishing operations

The document provides an overview of the sand casting process from pattern making to final inspection and packaging for shipment.

Ch2 foundaryproc Erdi Karaçal Mechanical Engineer University of Gaziantep

This document provides an overview of foundry processes. It discusses how molds are made by preparing sand and pouring molten metal into prepared molds. Key steps include making molds and cores, melting and pouring metals, and allowing the casting to solidify. Molds are prepared using patterns and sand, and may use cores to create internal cavities. The document outlines important mold characteristics and different types of molds, cores, and sand used in the casting process.

metal_casting

There are two main categories of metal casting processes: expendable mold processes where the mold is destroyed to remove the part, and permanent mold processes where the metal mold can be reused. Sand casting is the most widely used casting process, accounting for the majority of total tonnage cast, and allows for casting of nearly all alloys. It involves making a sand mold by packing sand around a pattern, then pouring molten metal and allowing it to solidify before breaking apart the mold to remove the casting.

12.casting of metals

Metal casting is a manufacturing process where liquid metal is poured into a mold and solidifies. Sand casting is a common type of metal casting that uses sand as the mold material. Key steps in sand casting include pattern making, molding, melting and pouring the metal, solidification, and cleaning. Sand provides advantages as a mold material such as low cost, high temperature stability, and permeability. Shell molding is an alternative casting method that uses a resin-bonded sand mixture to form the mold around a pattern.

Ceramics1

Ceramics are inorganic, non-metallic materials processed at high temperatures. They are composed of clays, sand, and feldspar. The main types of ceramics are whitewares, refractories, glasses, abrasives, and cements. Ceramics have various applications including crockery, tiles, furnace bricks, glass containers, and armor protection. Advanced ceramics like silicon carbide are used in automotive and body armor components due to their heat resistance, wear resistance, and ballistic properties.

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Metal Casting Technologu

This document provides information about the Metal Casting Technology course offered at VIT University. It includes details about the course faculty, textbooks, evaluation methods, and modules. The first module introduces metal casting processes, foundry industry basics, casting principles, and moulding practices. It also defines important casting terminology and properties of moulding sand like permeability and refractory properties. Common moulding equipment, patterns, and gating systems are also summarized.

Cermet

Cermets are composite materials composed of ceramic and metal materials. They are designed to have the optimal properties of both ceramics, such as high temperature resistance and hardness, and metals, such as the ability to undergo plastic deformation. Common ceramics in cermets include tungsten carbide, molybdenum boride, and aluminum oxide, while common metals are iron, cobalt, nickel, and chromium. Cermets are used in manufacturing electronic components, spacecraft shielding, bioceramics, transportation brake and clutch materials, armor, and nuclear applications due to their high temperature resistance, hardness, plastic deformation ability, wear and corrosion resistance, strength, and thermal conductivity.

Sand Casting

Sand casting is an old casting method still widely used today to make metal products like wall plaques and nut crackers from steel and aluminum. The process involves creating a sand mold with sprue pins and feeders, pouring molten metal into the mold cavity, and removing runners, risers, and feeders after solidification before dispatching the product.

Engineering materials 06

This document discusses different types of ceramic materials and their applications. It describes glasses, glass-ceramics, clay products, refractories, and abrasives. Glasses are used for containers and lenses. Glass-ceramics have high strength and temperature capabilities and are used for ovenware and electronics. Clay products include bricks, tiles, and pottery. Refractories withstand high temperatures and include fireclay, silica, and basic bricks. Abrasives like silicon carbide are used for grinding and require hardness.

Sand casting of metals - Gating system for sand casting mould

Topics covered: Sand Casting of Metals

Design and manufacture of gating system

Pouring basin

Sprue

Runners

In-gates

Riser

Lecture 2 casting full

This document provides information on the casting process, including definitions, components, steps, and considerations. Some key points:

1. The casting process involves pouring molten metal into a mold patterned after the part, allowing it to solidify, and removing the part from the mold. Important considerations are metal flow, solidification, and mold material.

2. Components include patterns, molds, cores, and gating systems. Steps are pattern making, molding, melting, pouring, solidification, cleaning, and inspection.

3. Patterns are modified replicas of the object and include allowances for shrinkage, draft, and machining. Common pattern materials are wood, metal, and plastic

METAL CASTING PROCESSES

This document provides an overview of sand casting processes. It discusses the key steps which include pattern making, molding sand properties and testing, core making, melting furnaces, casting defects and inspection methods. The main molding processes covered are green sand molding and dry sand molding. Common casting defects like blowholes and surface cracks are addressed. Non-destructive testing methods for inspecting castings such as magnetic particle, dye penetrant, radiography and ultrasonic testing are also summarized.

Metal casting process presentation

The metal casting process involves melting metal and pouring it into a mold to solidify into the shape of the mold cavity. Key steps include pattern making to create a physical model, core making to form interior surfaces, molding to prepare the mold, melting and pouring the molten metal, cleaning the casting, and inspecting the final product. Various sands are used in the molding process and properties like permeability and strength are important. The gating system delivers molten metal to the mold cavity uniformly during solidification. Foundries produce metal castings using furnaces and casting can have defects from stresses, shrinkage, gas pores, or issues with the mold material.

Sand Casting using 3D Printing

The method used to make a set of art castings. Using 3D printing technology to make complex sand cores, not possible by conventional processes.

Casting

Casting is a process where liquid material is poured into a mold and allowed to solidify. The solidified part that is formed is known as a casting. Casting dates back thousands of years, with early humans casting materials like gold, silver, and copper. Over time, casting processes evolved with advances in furnace technology, mold materials, and an increased understanding of metallurgy and solidification science. Modern casting involves pouring molten metal into a mold, which then solidifies to form the final part shape according to the mold cavity.

Met 402 mod_2

The document discusses the fundamentals of casting processes including solidification of metals, fluid flow of molten metal, casting defects and quality, and various casting processes such as sand casting and shell molding. It also covers topics like heat transfer during solidification, grain structure formation, and classifications of different casting techniques based on the type of mold and pattern used.

CERAMICS

Ceramics are inorganic, non-metallic materials made from a combination of metallic and non-metallic elements. They are frequently silicates, oxides, nitrides or carbides. Ceramics are typically insulative to heat and electricity, and resistant to high temperatures and harsh environments. Ceramic crystal structures are predominantly ionic in nature, with cations and anions arranged in repeating patterns depending on their size and charge. Ceramics exhibit extreme hardness, corrosion resistance, and heat resistance but are also brittle with low ductility. They are classified based on their composition into traditional ceramics, advanced ceramics, oxides, non-oxides, and composites.

Structural ceramics

This document discusses structural ceramics, including their mechanical properties, classifications, general properties, processing techniques, and areas of application. It describes how structural ceramics are used in applications requiring properties like strength, hardness, heat resistance, and chemical inertness. Examples given include wear parts, cutting tools, engine components, armor, semiconductor production equipment, steel making, and catalytic converters. The document provides details on the materials used and processing methods for different applications of structural ceramics.

Cutting tool material

The document discusses various cutting tool materials, their properties, manufacturing processes, and applications. It describes the key properties of wear resistance, hot hardness, and toughness that determine a material's performance as a cutting tool. Common materials discussed include carbon tool steel, high-speed steel, cast cobalt alloys, cemented carbides, ceramic, and diamond. Guidelines are provided for selecting the appropriate material based on the application.

introduction to ceramics

This document provides information on the properties of ceramics. It begins with an introduction to ceramics, including their atomic bonding and crystal structures. It then discusses defects in ceramics and general properties such as brittleness, toughness, and strength at high temperatures. The document classifies ceramics and discusses various types including electronic ceramics. It provides details on properties like piezoelectricity and applications of piezoelectric ceramics in devices. Processing methods for ceramics are also briefly mentioned.

Unit i

The document discusses various metal casting processes and techniques. It covers topics like sand casting, pattern making, moulding sand, cores, melting furnaces, and special casting processes. Sand casting is introduced as one of the most common casting methods where a sand mould is used. Different types of patterns and allowances are described. The properties and testing of moulding sands like green sand and dry sand are outlined. Special casting techniques like shell mould casting and investment casting that use non-sand moulds are also summarized briefly.

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Important Ceramics and their uses

Ceramics are inorganic materials known for their strength and heat resistance. They are formed through processes involving heating such as firing or sintering. Common ceramics include alumina, silicon carbide, and zirconia. Alumina is produced from bauxite and used in armor and abrasives. Silicon carbide is very hard and thermally conductive, making it useful for brakes, electronics, and furnace parts. Zirconia is used to make cubic zirconia gems and oxygen sensors. Ceramic composites like carbon-carbon are also used where high heat resistance is required. However, ceramic engines have not been commercially produced due to the difficulty of preventing cracks from forming.

Unit iv

The document discusses various sheet metal processes and forming techniques. It covers sheet metal characteristics and common operations like shearing, bending, drawing, and stretch forming. It also describes special forming processes such as hydroforming, rubber pad forming, spinning, explosive forming, magnetic pulse forming, and super plastic forming. Test methods for measuring formability are discussed as well. The document provides an overview of the different processes used to work with sheet metals.

Ceramic fibers

This document discusses ceramic fibers, including their production, classification, properties, and uses. Ceramic fibers are man-made heat resistant fibers produced through direct melt spinning or indirect chemical vapor deposition processes. They are classified based on their chemical composition as oxide fibers like silica and alumina or non-oxide fibers like silicon carbide. Ceramic fibers have properties of hardness, low density, high compressive strength, and excellent thermal resistance at high temperatures. Their main uses are as high temperature insulation and reinforcement in metal and ceramic matrix composites.

Metal casting ppt2

This document discusses various metal casting processes and their characteristics. It describes four main categories of casting processes: conventional moulding, chemical sand moulding, permanent mould processes, and special casting processes. Green sand moulding is the most common conventional process and uses sand mixed with clay as the mould material. Dry sand moulding bakes the mould to increase strength. Shell moulding uses a resin-bound sand mould only a few millimeters thick to provide a smooth surface finish. Investment casting allows for intricate parts by coating a wax pattern in refractory material before melting away the wax.

RAW MATEIAL and Heat Treatment process .ppt

This document provides an overview of a training programme on raw materials and heat treatment. It discusses the objectives of the training, which are to provide awareness of different raw material types, their characteristics, advantages, and examples used in the division. It then describes common product types like rolled products, forgings, castings, tubular products, and extrusions. The remainder of the document discusses these processes and material types in further detail, including definitions, considerations, defects, inspection methods, and more. It aims to educate participants on raw materials and manufacturing processes.

PATTERN ALLOWANCES IN CASTING CLASS: BY POLAYYA CHINTADA

This document discusses pattern allowances in metal casting processes. It provides definitions of patterns and explains the need for various pattern allowances to account for shrinkage, machining, drafts or tapers, potential distortions, and shaking during casting removal. The key allowances discussed are shrinkage allowance, machining or finishing allowance, draft allowance, distortion allowance, and shake allowance. Specific percentages and dimensions for these allowances are provided for different metals like cast iron, cast steel, aluminum, and magnesium.

More Related Content

What's hot

Cermet

Cermets are composite materials composed of ceramic and metal materials. They are designed to have the optimal properties of both ceramics, such as high temperature resistance and hardness, and metals, such as the ability to undergo plastic deformation. Common ceramics in cermets include tungsten carbide, molybdenum boride, and aluminum oxide, while common metals are iron, cobalt, nickel, and chromium. Cermets are used in manufacturing electronic components, spacecraft shielding, bioceramics, transportation brake and clutch materials, armor, and nuclear applications due to their high temperature resistance, hardness, plastic deformation ability, wear and corrosion resistance, strength, and thermal conductivity.

Sand Casting

Sand casting is an old casting method still widely used today to make metal products like wall plaques and nut crackers from steel and aluminum. The process involves creating a sand mold with sprue pins and feeders, pouring molten metal into the mold cavity, and removing runners, risers, and feeders after solidification before dispatching the product.

Engineering materials 06

This document discusses different types of ceramic materials and their applications. It describes glasses, glass-ceramics, clay products, refractories, and abrasives. Glasses are used for containers and lenses. Glass-ceramics have high strength and temperature capabilities and are used for ovenware and electronics. Clay products include bricks, tiles, and pottery. Refractories withstand high temperatures and include fireclay, silica, and basic bricks. Abrasives like silicon carbide are used for grinding and require hardness.

Sand casting of metals - Gating system for sand casting mould

Topics covered: Sand Casting of Metals

Design and manufacture of gating system

Pouring basin

Sprue

Runners

In-gates

Riser

Lecture 2 casting full

This document provides information on the casting process, including definitions, components, steps, and considerations. Some key points:

1. The casting process involves pouring molten metal into a mold patterned after the part, allowing it to solidify, and removing the part from the mold. Important considerations are metal flow, solidification, and mold material.

2. Components include patterns, molds, cores, and gating systems. Steps are pattern making, molding, melting, pouring, solidification, cleaning, and inspection.

3. Patterns are modified replicas of the object and include allowances for shrinkage, draft, and machining. Common pattern materials are wood, metal, and plastic

METAL CASTING PROCESSES

This document provides an overview of sand casting processes. It discusses the key steps which include pattern making, molding sand properties and testing, core making, melting furnaces, casting defects and inspection methods. The main molding processes covered are green sand molding and dry sand molding. Common casting defects like blowholes and surface cracks are addressed. Non-destructive testing methods for inspecting castings such as magnetic particle, dye penetrant, radiography and ultrasonic testing are also summarized.

Metal casting process presentation

The metal casting process involves melting metal and pouring it into a mold to solidify into the shape of the mold cavity. Key steps include pattern making to create a physical model, core making to form interior surfaces, molding to prepare the mold, melting and pouring the molten metal, cleaning the casting, and inspecting the final product. Various sands are used in the molding process and properties like permeability and strength are important. The gating system delivers molten metal to the mold cavity uniformly during solidification. Foundries produce metal castings using furnaces and casting can have defects from stresses, shrinkage, gas pores, or issues with the mold material.

Sand Casting using 3D Printing

The method used to make a set of art castings. Using 3D printing technology to make complex sand cores, not possible by conventional processes.

Casting

Casting is a process where liquid material is poured into a mold and allowed to solidify. The solidified part that is formed is known as a casting. Casting dates back thousands of years, with early humans casting materials like gold, silver, and copper. Over time, casting processes evolved with advances in furnace technology, mold materials, and an increased understanding of metallurgy and solidification science. Modern casting involves pouring molten metal into a mold, which then solidifies to form the final part shape according to the mold cavity.

Met 402 mod_2

The document discusses the fundamentals of casting processes including solidification of metals, fluid flow of molten metal, casting defects and quality, and various casting processes such as sand casting and shell molding. It also covers topics like heat transfer during solidification, grain structure formation, and classifications of different casting techniques based on the type of mold and pattern used.

CERAMICS

Ceramics are inorganic, non-metallic materials made from a combination of metallic and non-metallic elements. They are frequently silicates, oxides, nitrides or carbides. Ceramics are typically insulative to heat and electricity, and resistant to high temperatures and harsh environments. Ceramic crystal structures are predominantly ionic in nature, with cations and anions arranged in repeating patterns depending on their size and charge. Ceramics exhibit extreme hardness, corrosion resistance, and heat resistance but are also brittle with low ductility. They are classified based on their composition into traditional ceramics, advanced ceramics, oxides, non-oxides, and composites.

Structural ceramics

This document discusses structural ceramics, including their mechanical properties, classifications, general properties, processing techniques, and areas of application. It describes how structural ceramics are used in applications requiring properties like strength, hardness, heat resistance, and chemical inertness. Examples given include wear parts, cutting tools, engine components, armor, semiconductor production equipment, steel making, and catalytic converters. The document provides details on the materials used and processing methods for different applications of structural ceramics.

Cutting tool material

The document discusses various cutting tool materials, their properties, manufacturing processes, and applications. It describes the key properties of wear resistance, hot hardness, and toughness that determine a material's performance as a cutting tool. Common materials discussed include carbon tool steel, high-speed steel, cast cobalt alloys, cemented carbides, ceramic, and diamond. Guidelines are provided for selecting the appropriate material based on the application.

introduction to ceramics

This document provides information on the properties of ceramics. It begins with an introduction to ceramics, including their atomic bonding and crystal structures. It then discusses defects in ceramics and general properties such as brittleness, toughness, and strength at high temperatures. The document classifies ceramics and discusses various types including electronic ceramics. It provides details on properties like piezoelectricity and applications of piezoelectric ceramics in devices. Processing methods for ceramics are also briefly mentioned.

Unit i

The document discusses various metal casting processes and techniques. It covers topics like sand casting, pattern making, moulding sand, cores, melting furnaces, and special casting processes. Sand casting is introduced as one of the most common casting methods where a sand mould is used. Different types of patterns and allowances are described. The properties and testing of moulding sands like green sand and dry sand are outlined. Special casting techniques like shell mould casting and investment casting that use non-sand moulds are also summarized briefly.

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Important Ceramics and their uses

Ceramics are inorganic materials known for their strength and heat resistance. They are formed through processes involving heating such as firing or sintering. Common ceramics include alumina, silicon carbide, and zirconia. Alumina is produced from bauxite and used in armor and abrasives. Silicon carbide is very hard and thermally conductive, making it useful for brakes, electronics, and furnace parts. Zirconia is used to make cubic zirconia gems and oxygen sensors. Ceramic composites like carbon-carbon are also used where high heat resistance is required. However, ceramic engines have not been commercially produced due to the difficulty of preventing cracks from forming.

Unit iv

The document discusses various sheet metal processes and forming techniques. It covers sheet metal characteristics and common operations like shearing, bending, drawing, and stretch forming. It also describes special forming processes such as hydroforming, rubber pad forming, spinning, explosive forming, magnetic pulse forming, and super plastic forming. Test methods for measuring formability are discussed as well. The document provides an overview of the different processes used to work with sheet metals.

Ceramic fibers

This document discusses ceramic fibers, including their production, classification, properties, and uses. Ceramic fibers are man-made heat resistant fibers produced through direct melt spinning or indirect chemical vapor deposition processes. They are classified based on their chemical composition as oxide fibers like silica and alumina or non-oxide fibers like silicon carbide. Ceramic fibers have properties of hardness, low density, high compressive strength, and excellent thermal resistance at high temperatures. Their main uses are as high temperature insulation and reinforcement in metal and ceramic matrix composites.

Metal casting ppt2

This document discusses various metal casting processes and their characteristics. It describes four main categories of casting processes: conventional moulding, chemical sand moulding, permanent mould processes, and special casting processes. Green sand moulding is the most common conventional process and uses sand mixed with clay as the mould material. Dry sand moulding bakes the mould to increase strength. Shell moulding uses a resin-bound sand mould only a few millimeters thick to provide a smooth surface finish. Investment casting allows for intricate parts by coating a wax pattern in refractory material before melting away the wax.

What's hot (20)

Sand casting of metals - Gating system for sand casting mould

Sand casting of metals - Gating system for sand casting mould

Similar to 02 patterns

RAW MATEIAL and Heat Treatment process .ppt

This document provides an overview of a training programme on raw materials and heat treatment. It discusses the objectives of the training, which are to provide awareness of different raw material types, their characteristics, advantages, and examples used in the division. It then describes common product types like rolled products, forgings, castings, tubular products, and extrusions. The remainder of the document discusses these processes and material types in further detail, including definitions, considerations, defects, inspection methods, and more. It aims to educate participants on raw materials and manufacturing processes.

PATTERN ALLOWANCES IN CASTING CLASS: BY POLAYYA CHINTADA

This document discusses pattern allowances in metal casting processes. It provides definitions of patterns and explains the need for various pattern allowances to account for shrinkage, machining, drafts or tapers, potential distortions, and shaking during casting removal. The key allowances discussed are shrinkage allowance, machining or finishing allowance, draft allowance, distortion allowance, and shake allowance. Specific percentages and dimensions for these allowances are provided for different metals like cast iron, cast steel, aluminum, and magnesium.

Casting 091213101224-phpapp02

The document provides an overview of various casting methods including sand casting, investment casting, and die casting. It summarizes the key characteristics of each method such as typical metals used, size range, tolerances, surface finish, and process details. It also discusses related topics such as solidification and shrinkage, heat transfer considerations, pattern design guidelines, process variations, and potential environmental impacts.

Metal Casting Processes, Pattern, Solidification

The document discusses patterns used in casting processes. It describes that patterns are models constructed to form impressions in moulding sand which differ from the final casting due to allowances made. Various pattern materials are discussed such as wood, metals, and plastics. The types of patterns covered include single piece, split, loose piece, cope and drag, match plate, gated, sweep, segmental, skeleton, shell, built up, and left and right patterns. Factors influencing pattern selection include the casting shape, size, number required, and moulding method. Characteristics and functions of patterns are also summarized.

Casting

This document provides information on casting processes and terms. It defines casting as pouring molten metal into a mold cavity. Key terms discussed include patterns, cores, gates, risers, and molds. Sand casting is described as the most common casting method, using sand mixtures to form temporary molds. The document outlines the sand casting process and discusses mold properties. It also covers heating metal, pouring, solidification, and using risers to compensate for shrinkage. Overall, the document provides an overview of casting techniques and terminology.

Unit 2 Metal Casting.pptx

Unit 2 covers the metal casting process including sand molding, pattern and mold design, solidification, defects, and different casting methods like die casting and investment casting. It provides an overview of the key steps in casting like melting, pouring, solidification and finishing, and discusses factors like shrinkage and defects. Different casting methods are classified and compared in terms of capabilities, time, and applications.

Presentation study of manufacturing process in hmt machine tools limited.docx

Manufacturing is the production of products for use or sale using labour and machines, tools, chemical and biological processing, or formulation, and is the essence of secondary industry. The term may refer to a range of human activity, from handicraft to high-tech, but is most commonly applied to industrial design, in which raw materials from primary industry are transformed into finished goods on a large scale. Such finished goods may be sold to other manufacturers for the production of other more complex products or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers).

Manufacturing engineering or manufacturing process are the steps through which raw materials are transformed into a final product. The manufacturing process begins with the product design, and materials specification from which the product is made. These materials are then modified through manufacturing processes to become the required part.

The manufacturing sector is closely connected with engineering and industrial design. Examples of major manufacturers in North America include General Motors Corporation, General Cast Parts. Examples in Europe include Volkswagen Group, Siemens, FCA and Michelin. Examples in Asia include Toyota, Yamaha, Panasonic, LG, Samsung and Tata Motors.

Casting Process

Sand casting, investment casting, and die casting were discussed as the main casting methods. Key topics included mold filling and solidification, phase change and shrinkage during solidification, heat transfer considerations, and pattern design guidelines. Variations such as continuous casting and 3D printing of tooling were also mentioned. Environmental issues associated with casting operations like energy usage, emissions, and waste disposal were reviewed.

casting

Sand casting, investment casting, and die casting are the main casting methods discussed. Key topics include the casting process basics for each, phase change and shrinkage during solidification, heat transfer considerations, and pattern design guidelines. Variations and developments like continuous casting and 3D printing of investment tooling are also covered. Environmental impacts of casting such as energy use and emissions are reviewed.

Casting

This document summarizes key aspects of three metal casting methods: sand casting, investment casting, and die casting. It covers the basic processes, materials used, tolerances, surface finishes, design considerations, solidification and heat transfer principles, variations and developments in the technologies, and potential environmental issues. The goal is to provide an overview of the fundamentals and tradeoffs of different casting approaches.

Kinematics of Machinery Digital Material

Sand casting, investment casting, and die casting are the three main casting methods discussed. Sand casting uses a sand mold and can produce parts in most metals with complex geometries but rough surfaces. Investment casting uses a wax mold and yields complex parts in high temperature alloys with smoother finishes. Die casting injects molten metal into steel dies under pressure for aluminum, zinc, and magnesium alloys with smooth surfaces but moderate geometries. Key casting issues covered include phase change and shrinkage during solidification, heat transfer considerations, and pattern design guidelines. Variations like continuous casting and 3D printing of tooling were presented along with environmental impacts.

Casting VS Forging.pdf

Castings are integrally cast in the mold. Its stress distribution is uniform and there is no restriction on the compression direction. The forging is pressed by the force in the same direction, and its internal stress has directionality, so it can only bear the pressure with directionality.

ME6302 MANUFACTURING TECHNOLOGY – I BY Mr.K.SIVAKUMAR /AP/MECH/KIT/CBE

ME6302 MANUFACTURING TECHNOLOGY – I BY Mr.K.SIVAKUMAR /AP/MECH/KIT/CBEKIT-Kalaignar Karunanidhi Institute of Technology

The document discusses various manufacturing processes and focuses on metal casting and joining techniques. It provides details about different types of casting processes like sand casting, special casting processes including centrifugal casting, CO2 process, investment casting and shell moulding. It also describes metal joining techniques such as different welding processes, brazing and soldering. Defects in castings and welded joints are also discussed. The document is divided into five units covering metal casting, joining, forming, sheet metal working and plastic component manufacturing processes.Shell casting,steps involved in shell casting and Apllications by polayya chi...

This document provides information about shell casting production technology. It discusses shell casting as a metal casting process where a resin-coated sand forms an expendable mold, allowing for higher precision and productivity than sand casting. The document outlines the shell casting process which involves pattern creation, mold creation by coating a heated pattern with sand-resin mixture, mold assembly, pouring molten metal, cooling, and casting removal. Typical applications include small to medium parts for industries like automotive and defense.

PATTERN MATERIALS IN CASTING CLASS: BY POLAYYA CHINTADA

This document discusses pattern materials used in metal casting processes. It begins by defining a pattern as a replica of the component to be manufactured. Common pattern materials include wood, metal, plastic, wax and plaster. Wood patterns are inexpensive but can swell or shrink. Metal patterns are durable but more expensive. Plastic patterns are lightweight, durable and provide good surfaces. Wax patterns provide high accuracy and are used for investment casting. Plaster patterns can form intricate shapes but are only suitable for small castings. The document provides details on the properties, advantages and limitations of each material type.

Surface hardening processes

This document discusses surface hardening techniques. It states that heavy cross sections cannot be cooled quickly enough to produce a uniformly martensitic structure throughout, resulting in a softer unhardened core. It discusses various case hardening techniques like pack carburizing, liquid bath, and gas carburizing to increase the hardness of surfaces. It also covers nitriding, induction hardening, flame hardening, and other surface hardening methods like boronizing and carbonitriding. Heat treatment furnaces and protection of surfaces using metallic coatings is also summarized.

ME3393 MANUFACTURING PROCESSES PPT FOR III SEMESTER

Manufacturing processes document discusses various metal casting and joining processes. It provides details on sand casting, shell mold casting, investment casting, permanent mold casting, and die casting processes. It also describes welding techniques like shielded metal arc welding, gas tungsten arc welding, gas metal arc welding, submerged arc welding and resistance welding. Soldering and brazing metal joining processes are also summarized. The document concludes with descriptions of metal forming processes including rolling, forging, extrusion and drawing.

Metal rolling

Metal rolling is one of the most important metal forming processes. It involves plastically deforming metal between two rolls to reduce thickness and shape the metal. Most metals are hot rolled into basic shapes like blooms and slabs for further manufacturing. The rolls spin in opposite directions to feed and form the metal through compression. Friction must be controlled through lubrication. Rolling refines grain structure and spreads the width of the metal. Different roll materials, sizes, and mill configurations are used depending on the application. Surface defects can occur if scale or dirt are present while internal defects result from improper material distribution.

Casting

The document discusses different types of metal casting processes. It describes gravity die casting and pressure die casting as two types of die casting processes. Gravity die casting involves pouring molten metal into an open steel mold, allowing it to cool and solidify, then tapping the mold to release the casting. Pressure die casting forces metal under high pressure into molds called dies. The document also discusses vacuum permanent mold casting and compares attributes of different casting processes like maximum size, tolerance, and economic quantity.

Design of ceramics

This document discusses the design considerations for ceramic materials. It first classifies ceramics as inorganic compounds with complex crystal structures containing ionic and covalent bonds. This makes ceramics strong but also brittle with low mechanical strength. Key design considerations include accounting for their brittleness by placing ceramic parts under compression and avoiding tension. Dimensional changes during drying and firing must also be considered. Fracture mechanics is important for ceramic design given their susceptibility to cracking. Thermal shock resistance depends on factors like the material's flexural strength and thermal expansion coefficient.

Similar to 02 patterns (20)

PATTERN ALLOWANCES IN CASTING CLASS: BY POLAYYA CHINTADA

PATTERN ALLOWANCES IN CASTING CLASS: BY POLAYYA CHINTADA

Presentation study of manufacturing process in hmt machine tools limited.docx

Presentation study of manufacturing process in hmt machine tools limited.docx

ME6302 MANUFACTURING TECHNOLOGY – I BY Mr.K.SIVAKUMAR /AP/MECH/KIT/CBE

ME6302 MANUFACTURING TECHNOLOGY – I BY Mr.K.SIVAKUMAR /AP/MECH/KIT/CBE

Shell casting,steps involved in shell casting and Apllications by polayya chi...

Shell casting,steps involved in shell casting and Apllications by polayya chi...

PATTERN MATERIALS IN CASTING CLASS: BY POLAYYA CHINTADA

PATTERN MATERIALS IN CASTING CLASS: BY POLAYYA CHINTADA

ME3393 MANUFACTURING PROCESSES PPT FOR III SEMESTER

ME3393 MANUFACTURING PROCESSES PPT FOR III SEMESTER

Recently uploaded

Prediction of Electrical Energy Efficiency Using Information on Consumer's Ac...

Energy efficiency has been important since the latter part of the last century. The main object of this survey is to determine the energy efficiency knowledge among consumers. Two separate districts in Bangladesh are selected to conduct the survey on households and showrooms about the energy and seller also. The survey uses the data to find some regression equations from which it is easy to predict energy efficiency knowledge. The data is analyzed and calculated based on five important criteria. The initial target was to find some factors that help predict a person's energy efficiency knowledge. From the survey, it is found that the energy efficiency awareness among the people of our country is very low. Relationships between household energy use behaviors are estimated using a unique dataset of about 40 households and 20 showrooms in Bangladesh's Chapainawabganj and Bagerhat districts. Knowledge of energy consumption and energy efficiency technology options is found to be associated with household use of energy conservation practices. Household characteristics also influence household energy use behavior. Younger household cohorts are more likely to adopt energy-efficient technologies and energy conservation practices and place primary importance on energy saving for environmental reasons. Education also influences attitudes toward energy conservation in Bangladesh. Low-education households indicate they primarily save electricity for the environment while high-education households indicate they are motivated by environmental concerns.

Software Engineering and Project Management - Software Testing + Agile Method...

Software Testing: A Strategic Approach to Software Testing, Strategic Issues, Test Strategies for Conventional Software, Test Strategies for Object -Oriented Software, Validation Testing, System Testing, The Art of Debugging.

Agile Methodology: Before Agile – Waterfall, Agile Development.

Tools & Techniques for Commissioning and Maintaining PV Systems W-Animations ...

Join us for this solutions-based webinar on the tools and techniques for commissioning and maintaining PV Systems. In this session, we'll review the process of building and maintaining a solar array, starting with installation and commissioning, then reviewing operations and maintenance of the system. This course will review insulation resistance testing, I-V curve testing, earth-bond continuity, ground resistance testing, performance tests, visual inspections, ground and arc fault testing procedures, and power quality analysis.

Fluke Solar Application Specialist Will White is presenting on this engaging topic:

Will has worked in the renewable energy industry since 2005, first as an installer for a small east coast solar integrator before adding sales, design, and project management to his skillset. In 2022, Will joined Fluke as a solar application specialist, where he supports their renewable energy testing equipment like IV-curve tracers, electrical meters, and thermal imaging cameras. Experienced in wind power, solar thermal, energy storage, and all scales of PV, Will has primarily focused on residential and small commercial systems. He is passionate about implementing high-quality, code-compliant installation techniques.

Blood finder application project report (1).pdf

Blood Finder is an emergency time app where a user can search for the blood banks as

well as the registered blood donors around Mumbai. This application also provide an

opportunity for the user of this application to become a registered donor for this user have

to enroll for the donor request from the application itself. If the admin wish to make user

a registered donor, with some of the formalities with the organization it can be done.

Specialization of this application is that the user will not have to register on sign-in for

searching the blood banks and blood donors it can be just done by installing the

application to the mobile.

The purpose of making this application is to save the user’s time for searching blood of

needed blood group during the time of the emergency.

This is an android application developed in Java and XML with the connectivity of

SQLite database. This application will provide most of basic functionality required for an

emergency time application. All the details of Blood banks and Blood donors are stored

in the database i.e. SQLite.

This application allowed the user to get all the information regarding blood banks and

blood donors such as Name, Number, Address, Blood Group, rather than searching it on

the different websites and wasting the precious time. This application is effective and

user friendly.

AI + Data Community Tour - Build the Next Generation of Apps with the Einstei...

AI + Data Community Tour - Build the Next Generation of Apps with the Einstei...Paris Salesforce Developer Group

Build the Next Generation of Apps with the Einstein 1 Platform.

Rejoignez Philippe Ozil pour une session de workshops qui vous guidera à travers les détails de la plateforme Einstein 1, l'importance des données pour la création d'applications d'intelligence artificielle et les différents outils et technologies que Salesforce propose pour vous apporter tous les bénéfices de l'IA.Pressure Relief valve used in flow line to release the over pressure at our d...

Pressure Relief valve used in flow line to release the over pressure at our desired pressure

Null Bangalore | Pentesters Approach to AWS IAM

#Abstract:

- Learn more about the real-world methods for auditing AWS IAM (Identity and Access Management) as a pentester. So let us proceed with a brief discussion of IAM as well as some typical misconfigurations and their potential exploits in order to reinforce the understanding of IAM security best practices.

- Gain actionable insights into AWS IAM policies and roles, using hands on approach.

#Prerequisites:

- Basic understanding of AWS services and architecture

- Familiarity with cloud security concepts

- Experience using the AWS Management Console or AWS CLI.

- For hands on lab create account on [killercoda.com](https://killercoda.com/cloudsecurity-scenario/)

# Scenario Covered:

- Basics of IAM in AWS

- Implementing IAM Policies with Least Privilege to Manage S3 Bucket

- Objective: Create an S3 bucket with least privilege IAM policy and validate access.

- Steps:

- Create S3 bucket.

- Attach least privilege policy to IAM user.

- Validate access.

- Exploiting IAM PassRole Misconfiguration

-Allows a user to pass a specific IAM role to an AWS service (ec2), typically used for service access delegation. Then exploit PassRole Misconfiguration granting unauthorized access to sensitive resources.

- Objective: Demonstrate how a PassRole misconfiguration can grant unauthorized access.

- Steps:

- Allow user to pass IAM role to EC2.

- Exploit misconfiguration for unauthorized access.

- Access sensitive resources.

- Exploiting IAM AssumeRole Misconfiguration with Overly Permissive Role

- An overly permissive IAM role configuration can lead to privilege escalation by creating a role with administrative privileges and allow a user to assume this role.

- Objective: Show how overly permissive IAM roles can lead to privilege escalation.

- Steps:

- Create role with administrative privileges.

- Allow user to assume the role.

- Perform administrative actions.

- Differentiation between PassRole vs AssumeRole

Try at [killercoda.com](https://killercoda.com/cloudsecurity-scenario/)

Open Channel Flow: fluid flow with a free surface

Open Channel Flow: This topic focuses on fluid flow with a free surface, such as in rivers, canals, and drainage ditches. Key concepts include the classification of flow types (steady vs. unsteady, uniform vs. non-uniform), hydraulic radius, flow resistance, Manning's equation, critical flow conditions, and energy and momentum principles. It also covers flow measurement techniques, gradually varied flow analysis, and the design of open channels. Understanding these principles is vital for effective water resource management and engineering applications.

LLM Fine Tuning with QLoRA Cassandra Lunch 4, presented by Anant

Slides for the 4th Presentation on LLM Fine-Tuning with QLoRA Presented by Anant, featuring DataStax Astra

一比一原版(USF毕业证)旧金山大学毕业证如何办理

原件一模一样【微信:95270640】【旧金山大学毕业证USF学位证成绩单】【微信:95270640】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【微信:95270640】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【微信:95270640】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份【微信:95270640】

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

办理旧金山大学毕业证毕业证学位证USF学位证【微信:95270640 】外观非常精致,由特殊纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理旧金山大学毕业证USF学位证毕业证学位证【微信:95270640 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理旧金山大学毕业证毕业证学位证USF学位证【微信:95270640 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理旧金山大学毕业证毕业证学位证USF学位证【微信:95270640 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

Applications of artificial Intelligence in Mechanical Engineering.pdf

Historically, mechanical engineering has relied heavily on human expertise and empirical methods to solve complex problems. With the introduction of computer-aided design (CAD) and finite element analysis (FEA), the field took its first steps towards digitization. These tools allowed engineers to simulate and analyze mechanical systems with greater accuracy and efficiency. However, the sheer volume of data generated by modern engineering systems and the increasing complexity of these systems have necessitated more advanced analytical tools, paving the way for AI.

AI offers the capability to process vast amounts of data, identify patterns, and make predictions with a level of speed and accuracy unattainable by traditional methods. This has profound implications for mechanical engineering, enabling more efficient design processes, predictive maintenance strategies, and optimized manufacturing operations. AI-driven tools can learn from historical data, adapt to new information, and continuously improve their performance, making them invaluable in tackling the multifaceted challenges of modern mechanical engineering.

一比一原版(uoft毕业证书)加拿大多伦多大学毕业证如何办理

原版一模一样【微信:741003700 】【(uoft毕业证书)加拿大多伦多大学毕业证成绩单】【微信:741003700 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

【主营项目】

一.毕业证【q微741003700】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微741003700】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】外观非常简单,由纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

Use PyCharm for remote debugging of WSL on a Windo cf5c162d672e4e58b4dde5d797...

This document serves as a comprehensive step-by-step guide on how to effectively use PyCharm for remote debugging of the Windows Subsystem for Linux (WSL) on a local Windows machine. It meticulously outlines several critical steps in the process, starting with the crucial task of enabling permissions, followed by the installation and configuration of WSL.

The guide then proceeds to explain how to set up the SSH service within the WSL environment, an integral part of the process. Alongside this, it also provides detailed instructions on how to modify the inbound rules of the Windows firewall to facilitate the process, ensuring that there are no connectivity issues that could potentially hinder the debugging process.

The document further emphasizes on the importance of checking the connection between the Windows and WSL environments, providing instructions on how to ensure that the connection is optimal and ready for remote debugging.

It also offers an in-depth guide on how to configure the WSL interpreter and files within the PyCharm environment. This is essential for ensuring that the debugging process is set up correctly and that the program can be run effectively within the WSL terminal.

Additionally, the document provides guidance on how to set up breakpoints for debugging, a fundamental aspect of the debugging process which allows the developer to stop the execution of their code at certain points and inspect their program at those stages.

Finally, the document concludes by providing a link to a reference blog. This blog offers additional information and guidance on configuring the remote Python interpreter in PyCharm, providing the reader with a well-rounded understanding of the process.

一比一原版(osu毕业证书)美国俄勒冈州立大学毕业证如何办理

原版一模一样【微信:741003700 】【(osu毕业证书)美国俄勒冈州立大学毕业证成绩单】【微信:741003700 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

【主营项目】

一.毕业证【q微741003700】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微741003700】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

办理(osu毕业证书)美国俄勒冈州立大学毕业证【微信:741003700 】外观非常简单,由纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理(osu毕业证书)美国俄勒冈州立大学毕业证【微信:741003700 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理(osu毕业证书)美国俄勒冈州立大学毕业证【微信:741003700 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理(osu毕业证书)美国俄勒冈州立大学毕业证【微信:741003700 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

Mechanical Engineering on AAI Summer Training Report-003.pdf

Mechanical Engineering PROJECT REPORT ON SUMMER VOCATIONAL TRAINING

AT MBB AIRPORT

OOPS_Lab_Manual - programs using C++ programming language

This manual contains programs on object oriented programming concepts using C++ language.

Recently uploaded (20)

Prediction of Electrical Energy Efficiency Using Information on Consumer's Ac...

Prediction of Electrical Energy Efficiency Using Information on Consumer's Ac...

Software Engineering and Project Management - Software Testing + Agile Method...

Software Engineering and Project Management - Software Testing + Agile Method...

Tools & Techniques for Commissioning and Maintaining PV Systems W-Animations ...

Tools & Techniques for Commissioning and Maintaining PV Systems W-Animations ...

AI + Data Community Tour - Build the Next Generation of Apps with the Einstei...

AI + Data Community Tour - Build the Next Generation of Apps with the Einstei...

Pressure Relief valve used in flow line to release the over pressure at our d...

Pressure Relief valve used in flow line to release the over pressure at our d...

LLM Fine Tuning with QLoRA Cassandra Lunch 4, presented by Anant

LLM Fine Tuning with QLoRA Cassandra Lunch 4, presented by Anant

Applications of artificial Intelligence in Mechanical Engineering.pdf

Applications of artificial Intelligence in Mechanical Engineering.pdf

Use PyCharm for remote debugging of WSL on a Windo cf5c162d672e4e58b4dde5d797...

Use PyCharm for remote debugging of WSL on a Windo cf5c162d672e4e58b4dde5d797...

Mechanical Engineering on AAI Summer Training Report-003.pdf

Mechanical Engineering on AAI Summer Training Report-003.pdf

OOPS_Lab_Manual - programs using C++ programming language

OOPS_Lab_Manual - programs using C++ programming language

02 patterns

- 1. STRUCTURE FOR PURE METALS: At the mould walls, metal cools rapidly. Produces solidified skin or shell (thickness depends on composition, mould temperature, mould size and shape etc) • These are of equiaxed structure. • Grains grow opposite to heat transfer through the mould • These are columnar grains • Driving force of the heat transfer is reduced away from the mould walls and blocking at the axis prevents further growth NITC

- 2. PURE METALS- Have clearly defined melting/freezing point, solidifies at a constant temperature. Eg: Al - 6600C, Fe - 15370C, and W- 34100C. NITC

- 3. Size and distribution of the overall grain structure throughout a casting depends on rate & direction of heat flow (Grain size influences strength, ductility, properties along different directions etc.) CONVECTION- TEMPERATURE GRADIENTS DUE TO DIFFERNCES IN THE DENSITY OF MOLTEN METAL AT DIFFERENT TEMPERATURES WITHIN THE FLUID - STRONGLY EFFECTS THE GRAIN SIZE. Outer chill zones do not occur in the absence of convection NITC

- 4. FOR ALLOYS: • Alloys solidify over a range of temperatures • Begins when temp. drops below liquidous, completed when it reaches solidous. • Within this temperature range, mushy or pasty state (Structure as in figure) • Inner zone can be extended throughout by adding a catalyst.- sodium, bismuth, tellurium, Mg (or by eliminating thermal gradient, i.e. eliminating convection. (Expts in space to see the effect of lack of gravity in eliminating convection) (refresh dendritic growth- branches of tree, interlock, each dendrite develops uniform composition, etc) NITC

- 5. SOLIDIFICATION TIME During solidification, thin solidified skin begins to form at the cool mould walls. Thickness increases with time. For flat mould walls thickness time (time doubled, thickness by 1.414) NITC

- 6. CHVORINOV’S RULE solidification time (t) is a function of volume of the casting and its surface area t = C ( volume/ surface area )2 C is a constant [depends on mould material, metal properties including latent heat, temperature] A large sphere solidifies and cools at a much slower rate than a small diameter sphere. (Eg- potatoes, one big and other small) Volume cube of diameter of sphere, surface area square of diameter NITC

- 7. Solidification time for various shapes: Eg: Three pieces cast with the SAME volume, but different shapes. (i)Sphere, (ii)Cube, (iii)Cylinder with height = diameter. Which piece solidifies the fastest? Solution: Solidification time = C (volume/surface area)2 Let volume = unity. As volume is same, t = C/ surface area2. Cylinder: V = πr2h = 2 π r3; ie, r = (1/2 π) 1/3 A = 2 πr2 + 2πrh = 6 πr2 = 5.54. Then, t cube = 0.028C ; t cylinder = 0.033C ; t sphere= 0.043C Metal poured to cube shaped mould solidifies the fastest. Sphere: V= 4/3 (π r3); i.e. r = (3/4 π)1/3 A= 4 π r2 = 4 π (3/4 π)1/3 = 4.84 Cube: V = a3; ie a = 1; A = 6 a2 = 6. NITC

- 8. SHRINKAGE AND POROSITY METALS SHRINK(CONTRACT) DURING SOLIDIFICATION - CAUSES DIMENSIONAL CHANGES LEADING TO CENTRE LINE SHRINKAGE, POROSITY, CRACKING TOO NITC

- 9. T Time 1 2 3 NITC SHRINKAGE DUE TO: (1).CONTRACTION OF MOLTEN METALAS IT COOLS PRIOR TO SOLIDIFICATION (2) CONTRACTION OF SOLIDIFYING METAL, LATENT HEAT OF FUSION (3) CONTRACTION OF SOLIDIFIED METAL DURING DROP TO AMBIENT TEMP OUT OF THESE, LARGEST SHRINKAGE DURING COOLING OF CASTING (ITEM 3) eg:pure metal

- 10. SOLIDIFICATION CONTRACTION FOR VARIOUS METALS METAL Volumetric Solidification Contraction Al 6.6 Grey cast Iron Expansion 2.5 Carbon Steel 2.5 to 3 Copper 4.9 Magnesium 4.2 Zinc 6.5 NITC

- 11. • POROSITY DUE TO SHRINKAGE OF GASES AND METAL TOO. RELATED TO DUCTILITY AND SURFACE FINISH (DUCTILITY V/S POROSITY CURVES FOR DIFFERENT METALS) - ELIMINATION BY VARIOUS MEANS (ADEQUATE SUPPLY OF LIQUID METAL, USE OF CHILLS, NARROWING MUSHY ZONE- CASTING SUBJECTED TO ISOSTATIC PRESSING NITC

- 12. POROSITY BY GASES LIQUID METALS HAVE HIGH SOLUBILITY FOR GASES DISSOLVED GASES EXPELLED FROM SOLUTION DURING SOLIDIFICATION (Hydrogen, Nitrogen mainly) ACCUMULATE IN REGIONS OF EXISTING POROSITY OR CAUSE MICROPOROSITY IN CASTING - TO BE CONTROLLED NITC

- 13. Effect of microporosity on the ductility of quenched and tempered cast steel – Porosity affects the ‘pressure tightness’ of cast pressure vessel Ductility Porosity(%) Elongation Reduction of area 0 5 10 15 NITC

- 14. FLOW OF MOLTEN METAL IN MOULDS Important: pouring basin, mould cavity & riser GATING SYSTEM Design -fluid flow, heat transfer, influence of temperature gradient, FLUID FLOW Without turbulence or with minimized turbulence HEAT FLOW INFLUENCED BY MANY FACTORS FLUIDITY-A characteristic related to viscosity. TEST OF FLUIDITY - USING A SPIRAL MOULD.Fluidity Index NITC

- 16. TEST FOR FLUIDITY USING A SPIRAL MOULD. FLUIDITY INDEX IS THE LENGTH OF THE SOLIDIFIED METAL IN THE SPIRAL PASSAGE. GREATER THE LENGTH, GREATER THE FLUIDITY INDEX.

- 17. PATTERN • Model of a casting constructed such that it forms an impression in moulding sand NITC

- 18. PATTERN • 1st step- Prepare model (pattern) Differs from the casting Differences Pattern Allowances. • To compensate for metal shrinkage, • Provide sufficient metal for machining • Easiness in moulding • As Shrinkage allowance, Draft allowance, Finishing allowance, Distortion or camber allowance, Shaking or rapping allowance NITC

- 19. MATERIAL 1. WOOD. 2. METAL Al, CI, Brass, 3. For special casting processes, Polystyrene which leaves mould as gas when heated also used. Types- many Simple-Identical patterns; Complex, intricate- with number of pieces. Single or loose piece; Split; gated; Match Plate; Sweep; Segmental; Skeleton(frame, ribbed), skell; Boxed Up; Odd shaped etc. Sketches-- NITC

- 20. Material 1. WOOD. (+) Cheap, easily available, light, easiness in surfacing, preserving (by shellac coating), workable, ease in joining, fabrication (-) Moisture effects, wear by sand abrasion, warp during forming, not for rough use. Must be properly dried/ seasoned, free from knots, straight grained Egs. Burma teak, pine wood, mahogany, Sal, Deodar, Shisham, Walnut, Apple tree NITC

- 21. 2. METAL: For durability, strength Egs: Al alloys, Brass, Mg alloys, Steel, cast Iron for mass production (first, wooden pattern is made, then cast in the metal) Type of material depends on shape, size, number of castings required, method of moulding etc. NITC

- 22. TYPES OF PATTERNS 1. SINGLE PIECE PATTERN. NIT CALICUT NITC

- 23. 2. SPLIT PATTERN (TWO PIECE ) NIT CALICUT NITC

- 24. 2. a, THREE PIECE SPLIT PATTERN NIT CALICUT NITC

- 25. 3. LOOSE PIECE PATTERN NIT CALICUT NITC

- 26. 4. COPE AND DRAG PATTERN • COPE AND DRAG PARTS OF THE PATTERN MOUNTED ON SEPARATE PLATES. • COPE HALF AND DRAG HALF MADE BY WORKING ON DIFFERENT MOULDING MACHINES. • THIS REDUCES THE SEPARATE COPE AND DRAG PLATE PREPARATION. • GENERALLY FOR HIGH SPEED MECHANISED MOULDING. NIT CALICUT NITC

- 27. 5. MATCH PLATE PATTERN – Pattern generally of metal and plate making parting line metal/wood. NIT CALICUT NITC

- 28. 6. FOLLOW BOARD PATTERN. For thin sections. NIT CALICUT NITC THIN PATTERN

- 29. 7. GATED PATTERN - Gating system is a part of the pattern. NIT CALICUT NITC

- 30. 8. SWEEP PATTERN – For large size castings in small numbers. Template of wood attached to a sweep used. NIT CALICUT NITC

- 31. 9. SEGMENTAL PATTERN – For rings, wheel rims, large size gears. NIT CALICUT NITC

- 32. 10. SKELETON PATTERN.- Stickle board used to scrape the excess sand. Eg. Oil pipes, water pipes, pipe bends, boxes, valve bodies etc. NIT CALICUT Stickle board NITC

- 34. 12. BUILT UP PATTERN – Also called lagged up patterns- For barrels, pipes, columns etc NIT CALICUT NITC

- 35. 13. LEFT AND RIGHT PATTERN – For parts to be made in pairs. Eg: legs of sewing machine, wood working lathe, garden benches, J hangers for shafts, brackets for luggage racks etc. NIT CALICUT NITC

- 36. • Type of pattern depends on: • Shape and size of casting, • number of castings required, • method of moulding employed, • easiness or difficulties of the moulding operations, • other factors peculiar to the casting. NIT CALICUT NITC

- 37. Metal Pattern Oversize Factor (each direction) Finish Allowance (smaller number for larger sizes) Min Wall mm Aluminum 1.08 - 1.12 0.5 to 1.0 % 4.75 Copper alloys 1.05 - 1.06 0.5 to 1.0 % 2.3 Gray Cast Iron 1.10 0.4 to 1.6 % 3.0 Nickel alloys 1.05 0.5 to 1.0 % N/A Steel 1.05 - 1.10 0.5 to 2 % 5 Magnesium alloys 1.07 - 1.10 0.5 to 1.0 % 4.0 Malleable Irons 1.06 - 1.19 0.6 to 1.6 % 3.0 Pattern, Finish Allowance, and Wall Thickness

- 38. CHARACTERISTICS OF PATTERN MATERIALS CHARACTERISTIC RATING WOOD AL STEEL PLASTIC CAST IRON MACHINABILITY E G F G G WEAR RESISTANCE P G E F E STRENGTH E G E G G WEIGHT E G P G P REPAIRABILITY E P G F G RESISTANCE TO: • CORROSION (by water) E E P E P • SWELLING P E E E E E- Excellent; G- Good; F-fair, P- Poor NITC

- 39. Functions of pattern • Moulding the Gating system; • Establishing a parting Line, • Making Cores, • Minimising casting Defects, • Providing Economy in moulding • Others, as needed