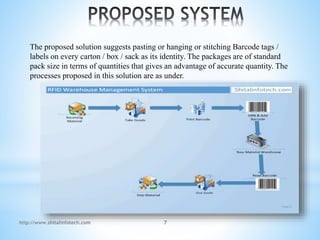

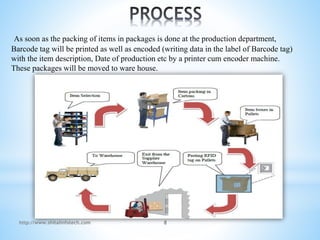

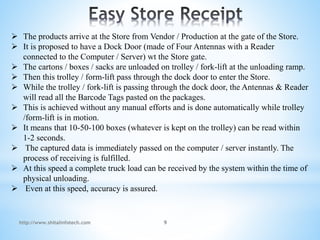

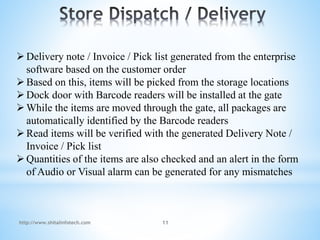

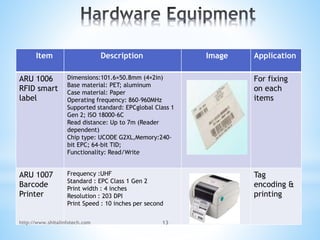

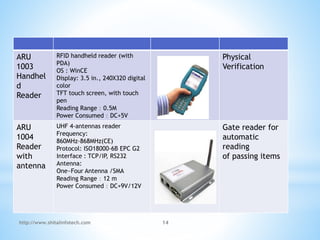

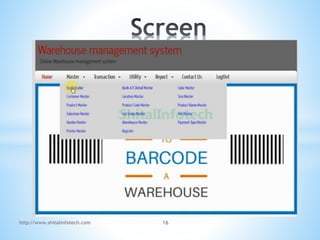

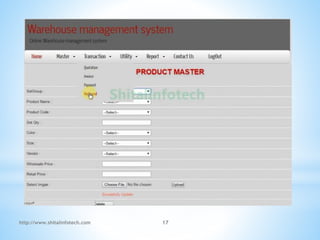

This document proposes an RFID-based inventory management system to address issues with an existing manual system such as errors, misidentification of items, poor space utilization, and inaccurate inventory visibility. The key features of the proposed system include automated receiving and dispatching of items using RFID readers, real-time tracking of inventory and supply chain visibility, and accurate data capture eliminating human errors. The system aims to reduce costs, increase productivity and provide valuable data analytics.