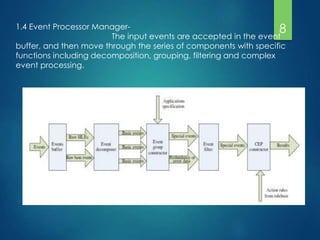

1) The document presents an RFID-based digital warehouse management system designed to improve operations in a traditional plane warehouse. Key problems addressed include storage/retrieval assignment, rapid and accurate picking, complex order efficiency, and inventory visibility.

2) The proposed system uses RFID technology to automatically identify products, integrate with a computer system, and provide functions like automatic storage/retrieval management, real-time inventory management, and accurate shelf management.

3) The system is divided into several subsystems including digital shelf management, forklift guidance, and rules management. It aims to reduce inventory errors, increase capacity, and lower operating costs through automated processes and inventory tracking.