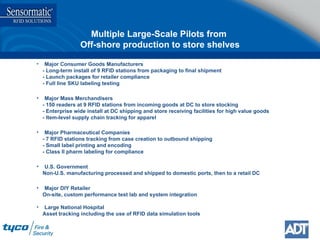

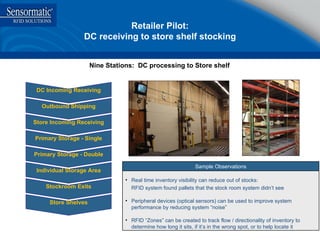

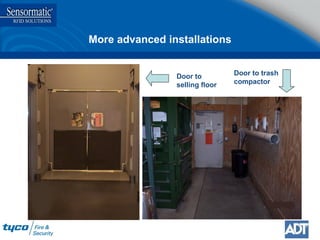

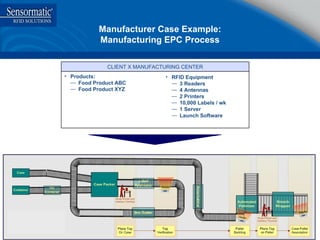

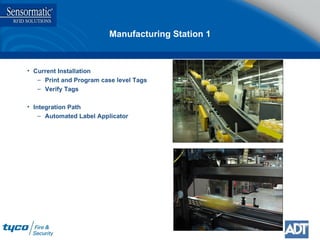

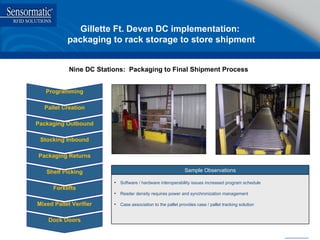

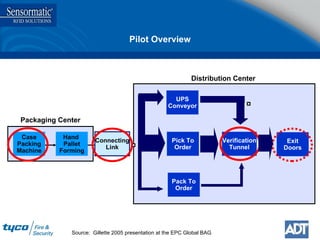

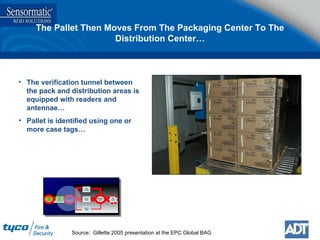

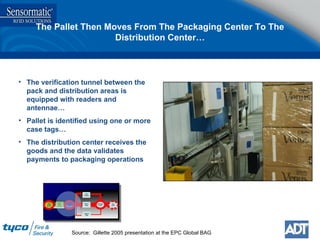

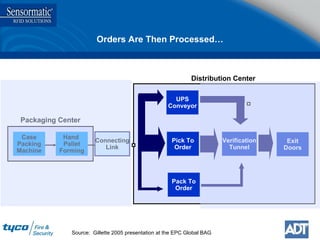

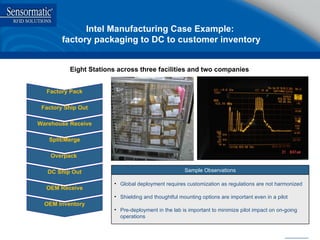

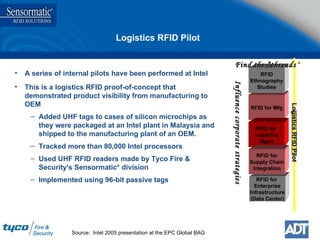

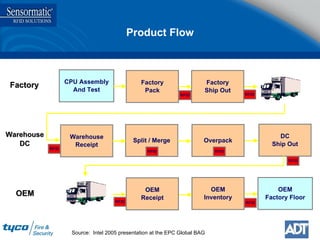

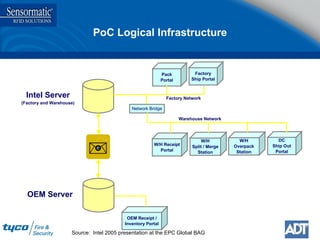

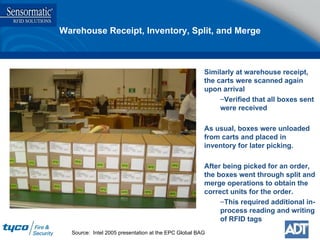

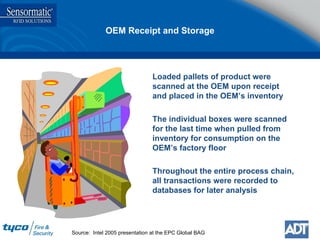

The document discusses several end-to-end RFID implementations across supply chains. It describes pilots conducted by various companies tracking items from manufacturing to distribution centers to store shelves. Key learnings included the need for robust hardware and software, customized solutions for different applications, and benefits like reduced inventory counting and verification times.

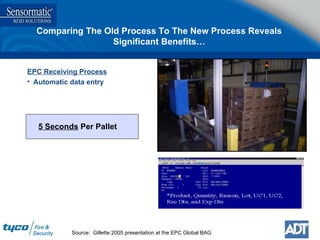

![Comparing The Old Process To The New Process Reveals Significant Benefits… Current Receiving Process Five Scans Three keyboard entries 20 Seconds Per Pallet Read container barcode for Part # & Quantity Enter Part # & Quantity Scan Unit of Measure Barcode Scan Reason Barcode Tab to Lot Code Field Scan Lot Code Barcode Scan Pallet ID from TIN Scan Bill of Lading Press [Enter] Source: Gillette 2005 presentation at the EPC Global BAG](https://image.slidesharecdn.com/conferenceboard03may05tycorfid-123962351248-phpapp01/85/Conference-Board-03-May-05-Tyco-Rfid-35-320.jpg)

![Thank You! George Reynolds Vice President, RFID Tyco Fire & Security [email_address]](https://image.slidesharecdn.com/conferenceboard03may05tycorfid-123962351248-phpapp01/85/Conference-Board-03-May-05-Tyco-Rfid-66-320.jpg)