The document discusses simulation as a technique for modeling real-world systems with uncertain inputs. It defines simulation as using models to represent systems over time to understand their behavior. The key aspects covered include:

- Components of a simulation model including inputs, calculations, and outputs

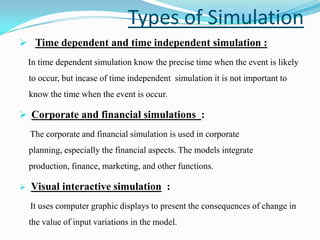

- Types of simulation like time-dependent vs time-independent and corporate/financial simulations

- Major applications in queuing systems and analyzing waiting times

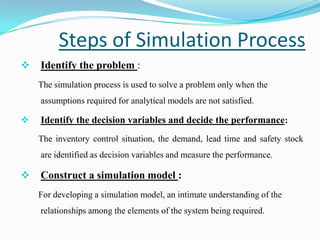

- Steps of the simulation process from identifying the problem to evaluating results

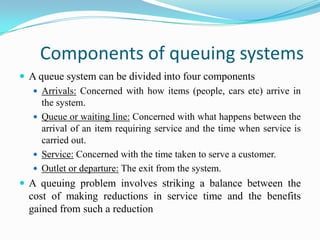

- Components and structures of queuing systems like arrivals, queues, service, and departure.