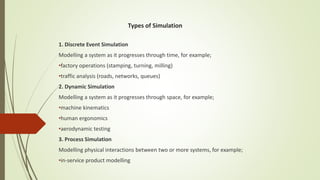

Simulation involves creating computer-based models to imitate real-world processes. The model represents key behaviors and characteristics of the selected process, and the simulation shows how the model evolves under different conditions over time. Simulations are used for decision-making, training, and understanding systems. They allow testing of scenarios and process changes in a safe environment without financial risks. Common types of simulation include discrete event simulation for processes like factory operations, dynamic simulation for machine kinematics, and process simulation for physical interactions between systems. Simulations are applied across industries for evaluation, prediction, and insights into performance improvement.

![Simulation

Navjeevan institute of management,Nashik

Name- Aadeshkumar Vijay Bhosale

Subject- Decision Sciences[302]

Class –MBA II

Guided by- Ms. Prajakta Shirode](https://image.slidesharecdn.com/simulation-230312103011-8de1df1c/75/Simulation-pptx-1-2048.jpg)