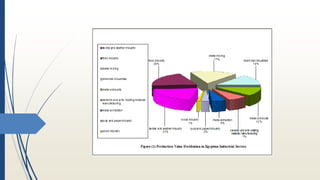

The document provides information on the ceramic industry in Egypt. Some key points:

- Ceramics make up 7% of Egyptian industrial production and include items made of clay and silicates.

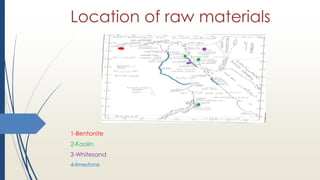

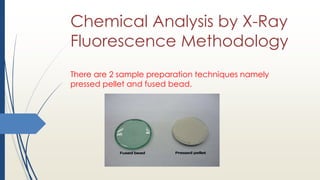

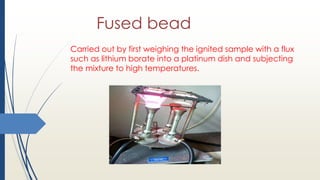

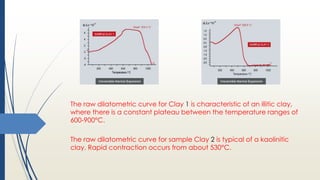

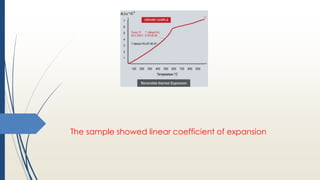

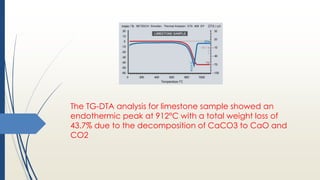

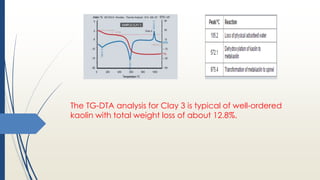

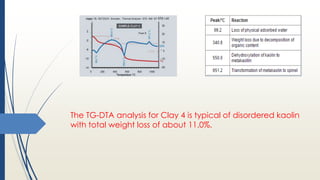

- Raw materials for ceramics include sand, feldspar, clay, and other minerals. Testing of raw materials includes chemical analysis by XRF and thermal analysis by dilatometry and TG-DTA.

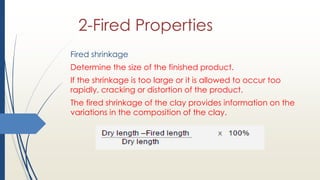

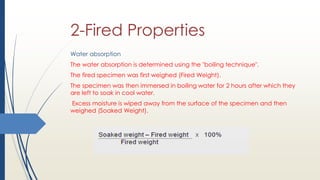

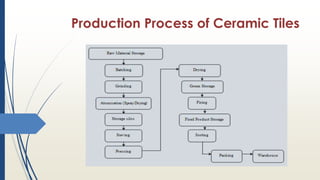

- The production process for ceramic tiles includes batching, grinding, spraying, pressing, drying, firing, and sorting. Finished tiles undergo tests for properties like dimensions, strength, and abrasion resistance.

- Emissions from the ceramic industry can impact the environment through air pollution, effluents,