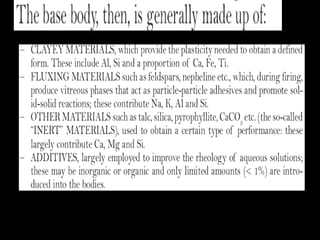

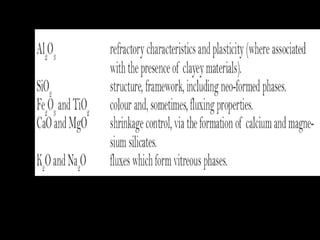

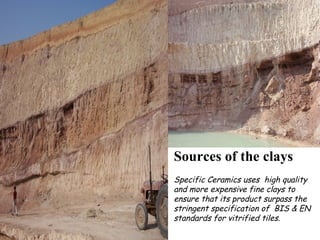

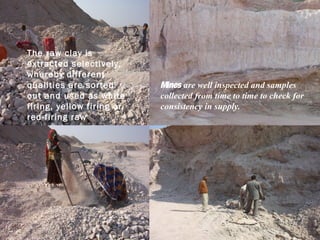

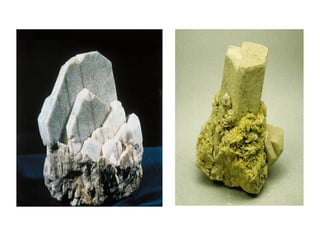

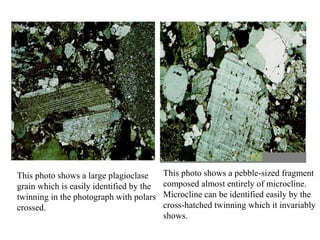

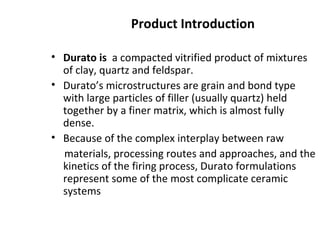

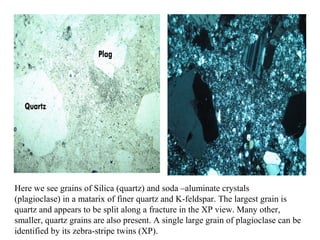

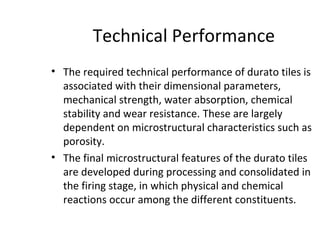

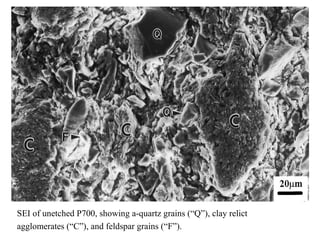

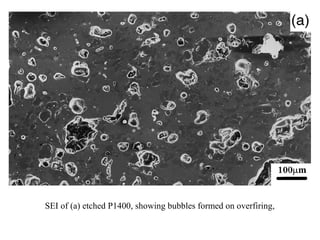

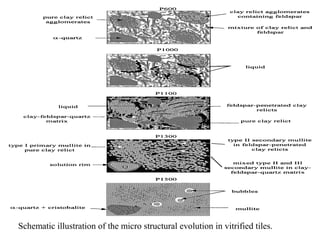

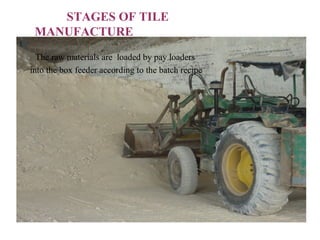

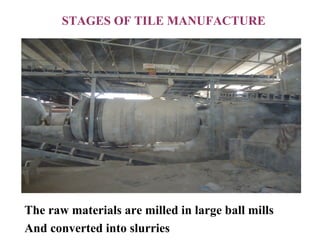

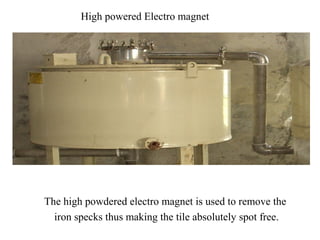

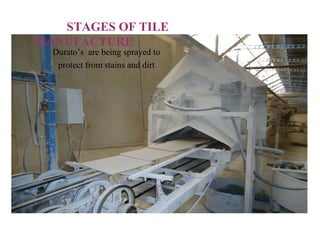

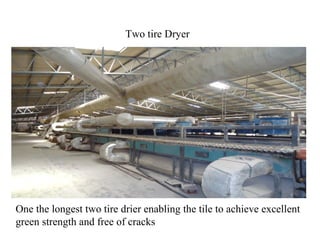

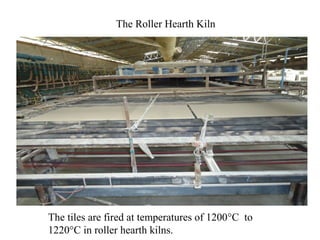

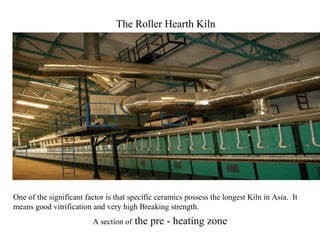

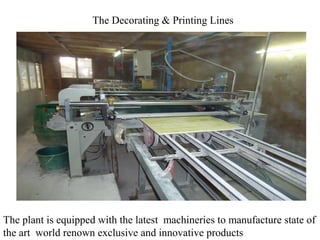

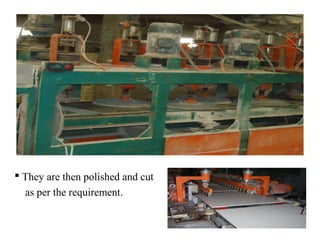

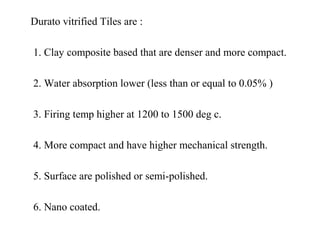

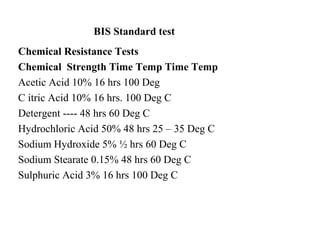

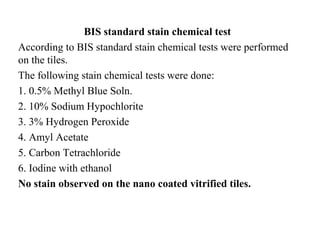

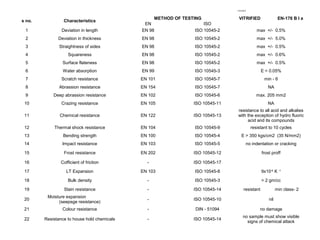

Specific Ceramics Ltd manufactures vitrified tiles under the brand Durato. The company aims to blend design and technology expertise to provide cost-effective tile solutions. The plant is located in Gujarat with modern infrastructure. Raw materials like clays, quartz and feldspar are carefully selected and tested. The manufacturing process involves grinding, pressing, drying, firing and additional treatments. Firing at high temperatures of 1200°C forms the glass-like structure of vitrified tiles, making them resistant to wear, abrasion and frost. Quality control tests are conducted at the in-house lab to ensure product performance.