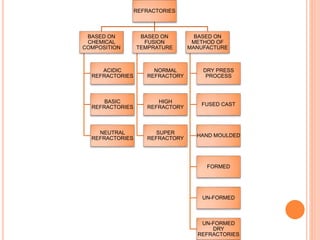

This document defines refractories as materials that can withstand high temperatures above 5000°C. Refractories have properties like thermal resistance, chemical inertness, and specific thermal conductivity. Common materials used in refractories include oxides of alumina, silica, magnesia, lime, and fire clays. Refractories are classified based on their chemical composition as acidic, basic, or neutral, and based on their fusion temperature as normal, high, or super refractories. Proper anchoring and controlled heating are important for refractories.