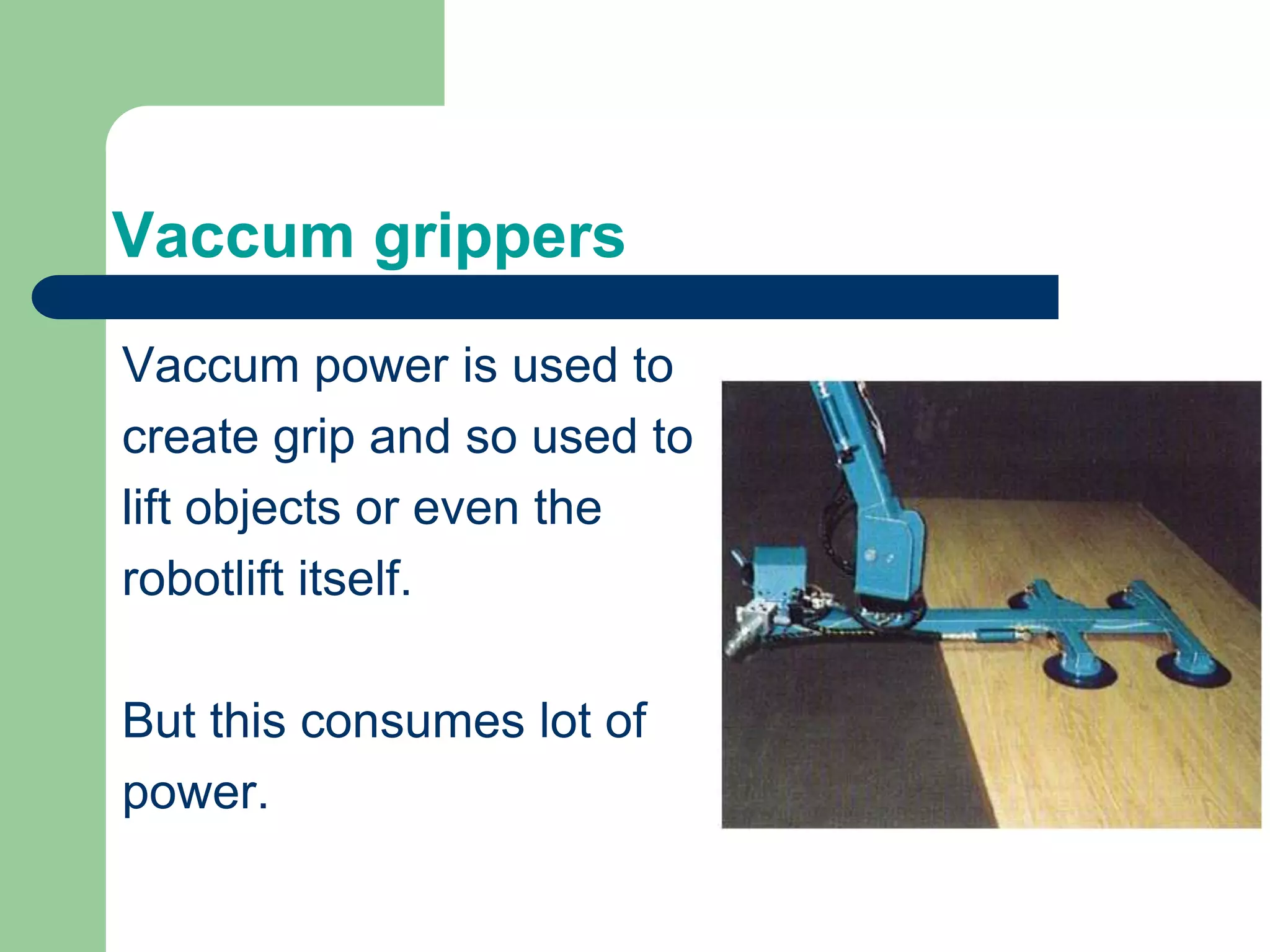

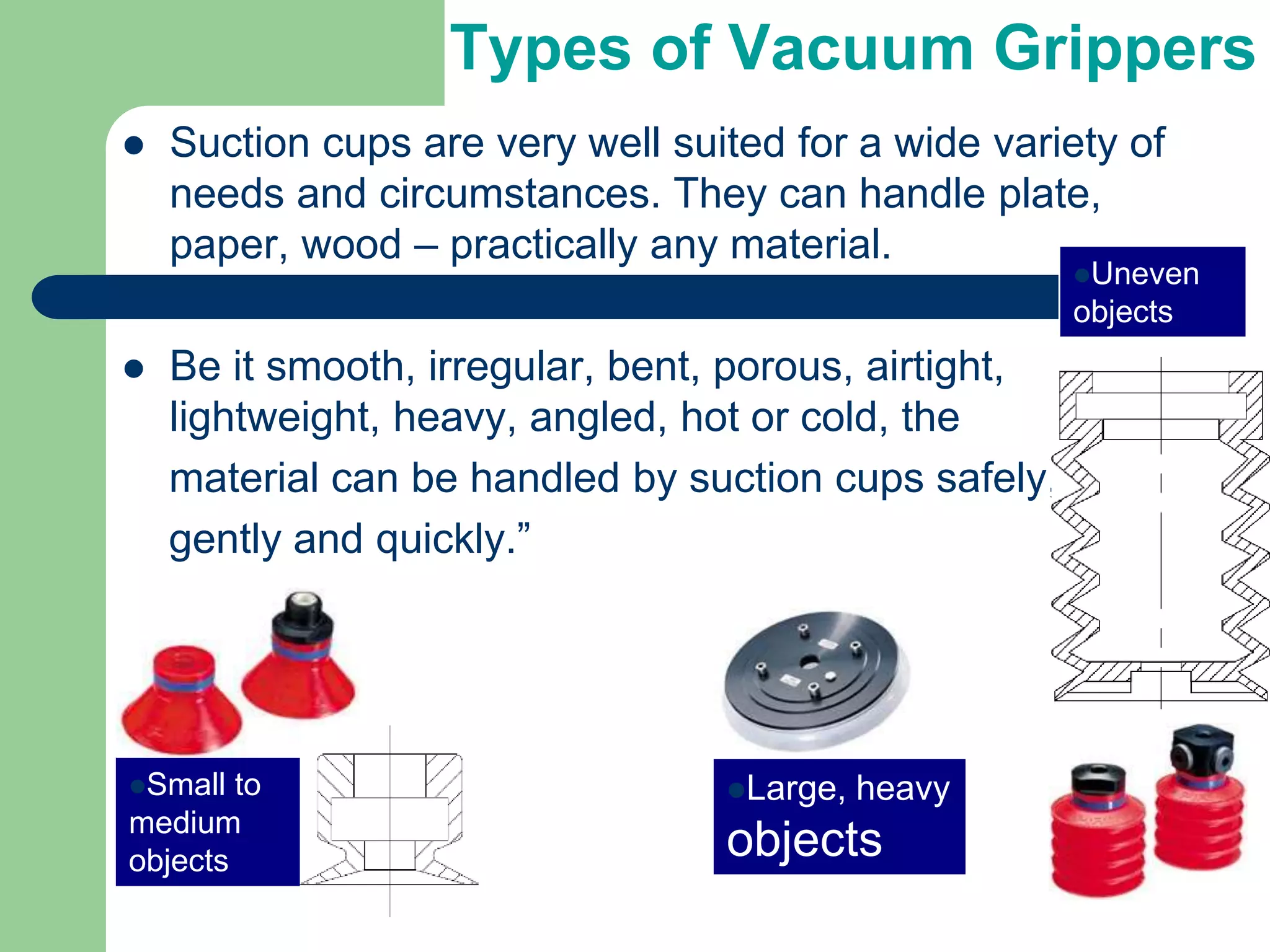

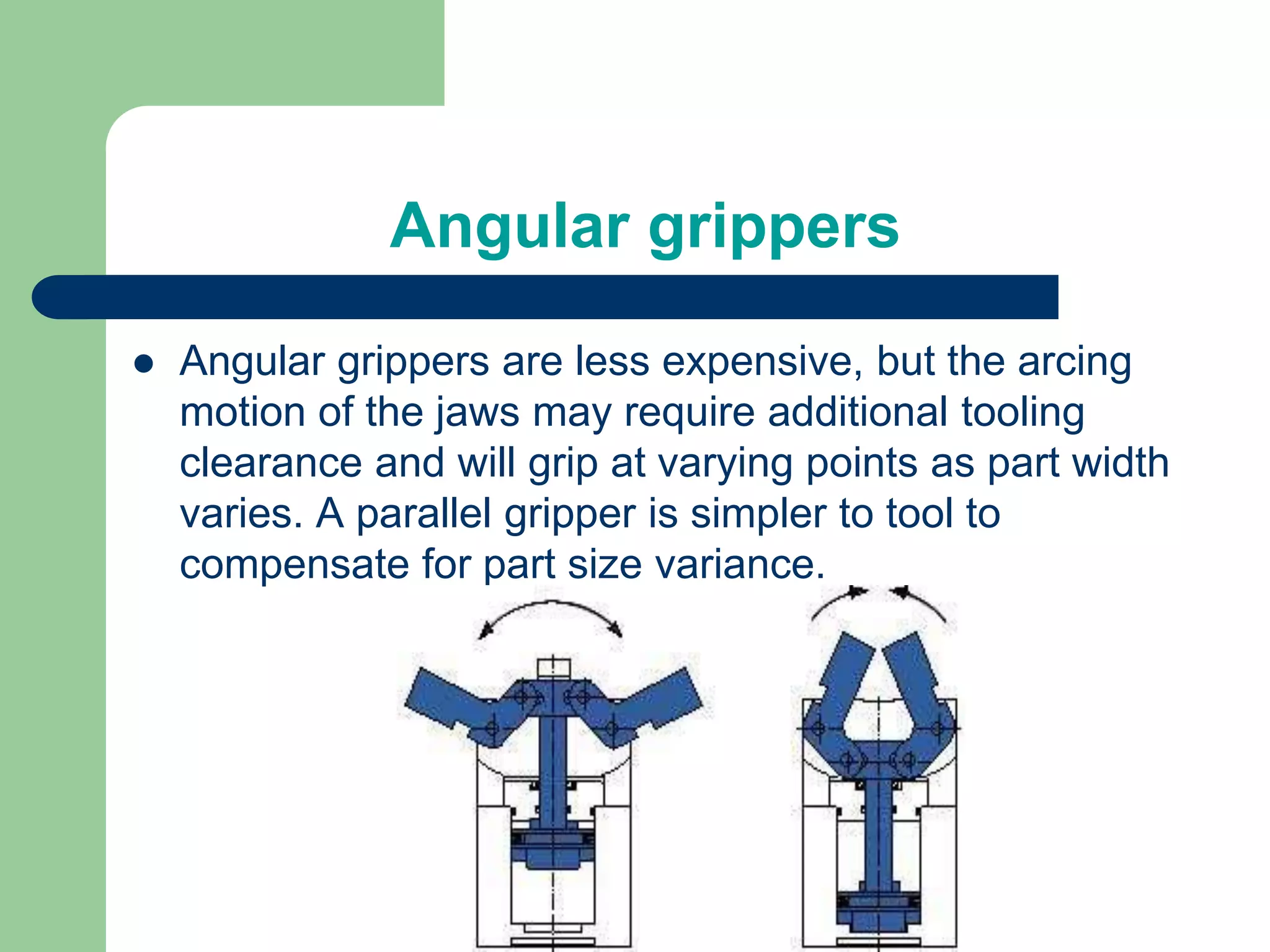

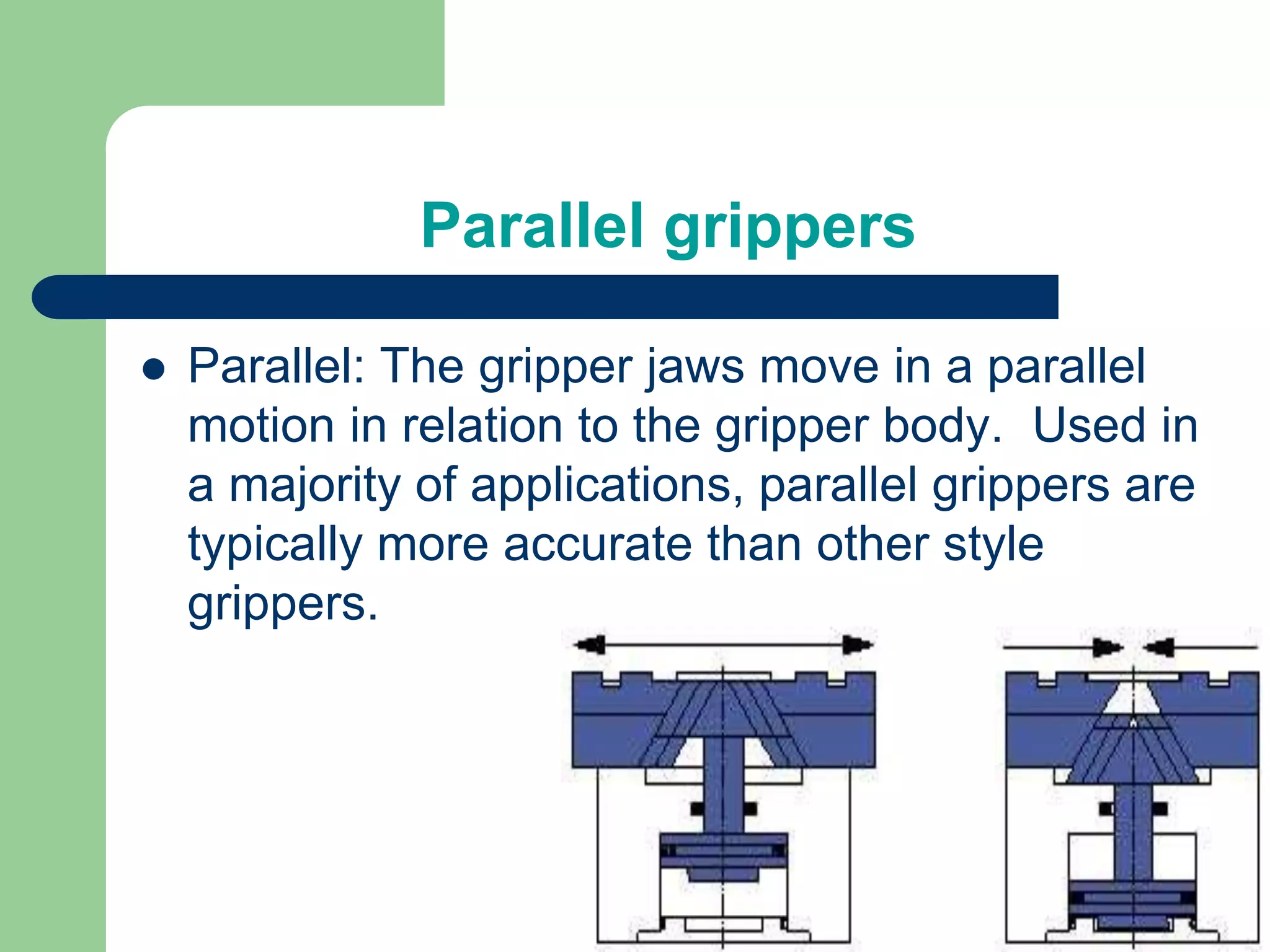

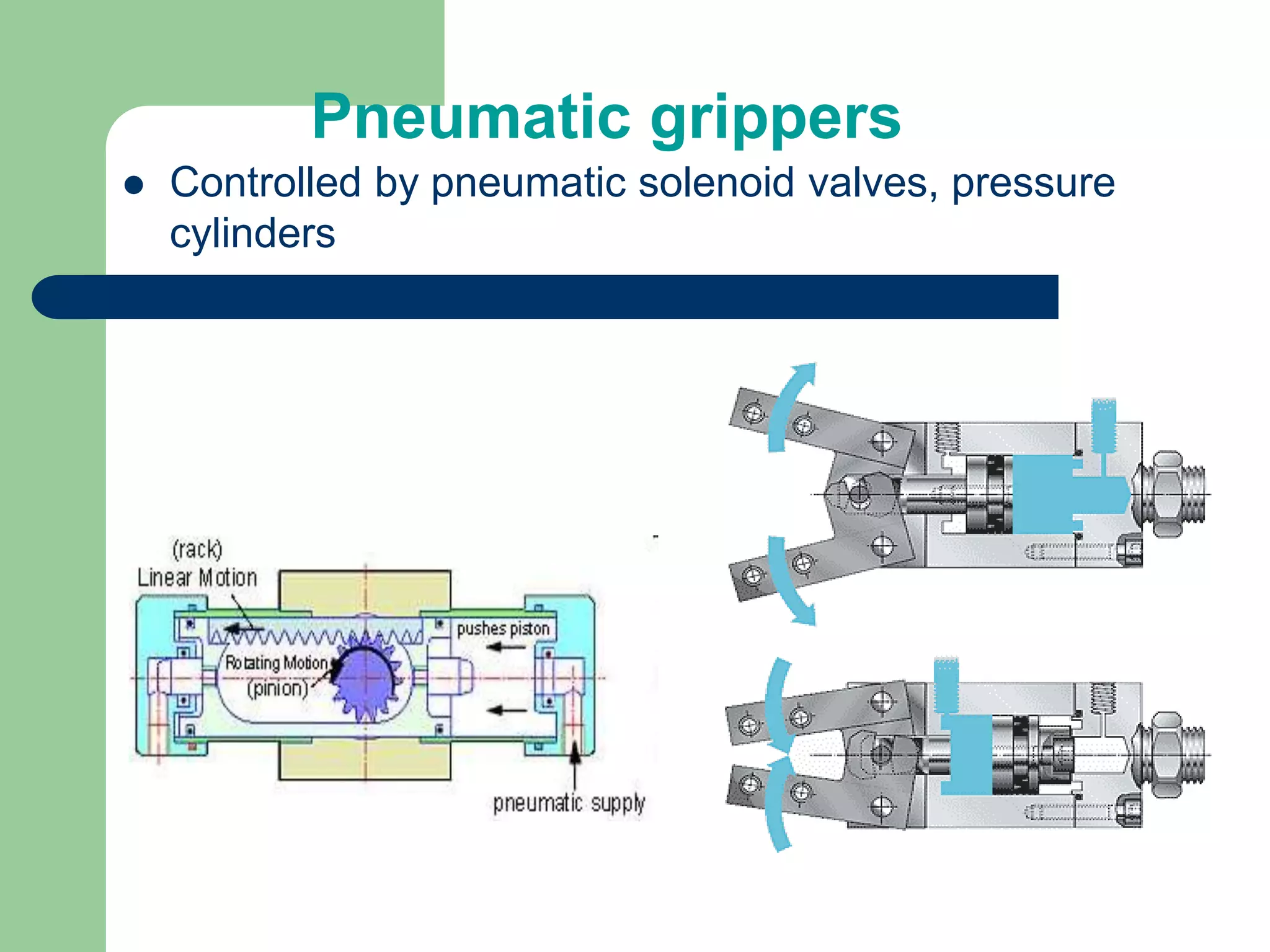

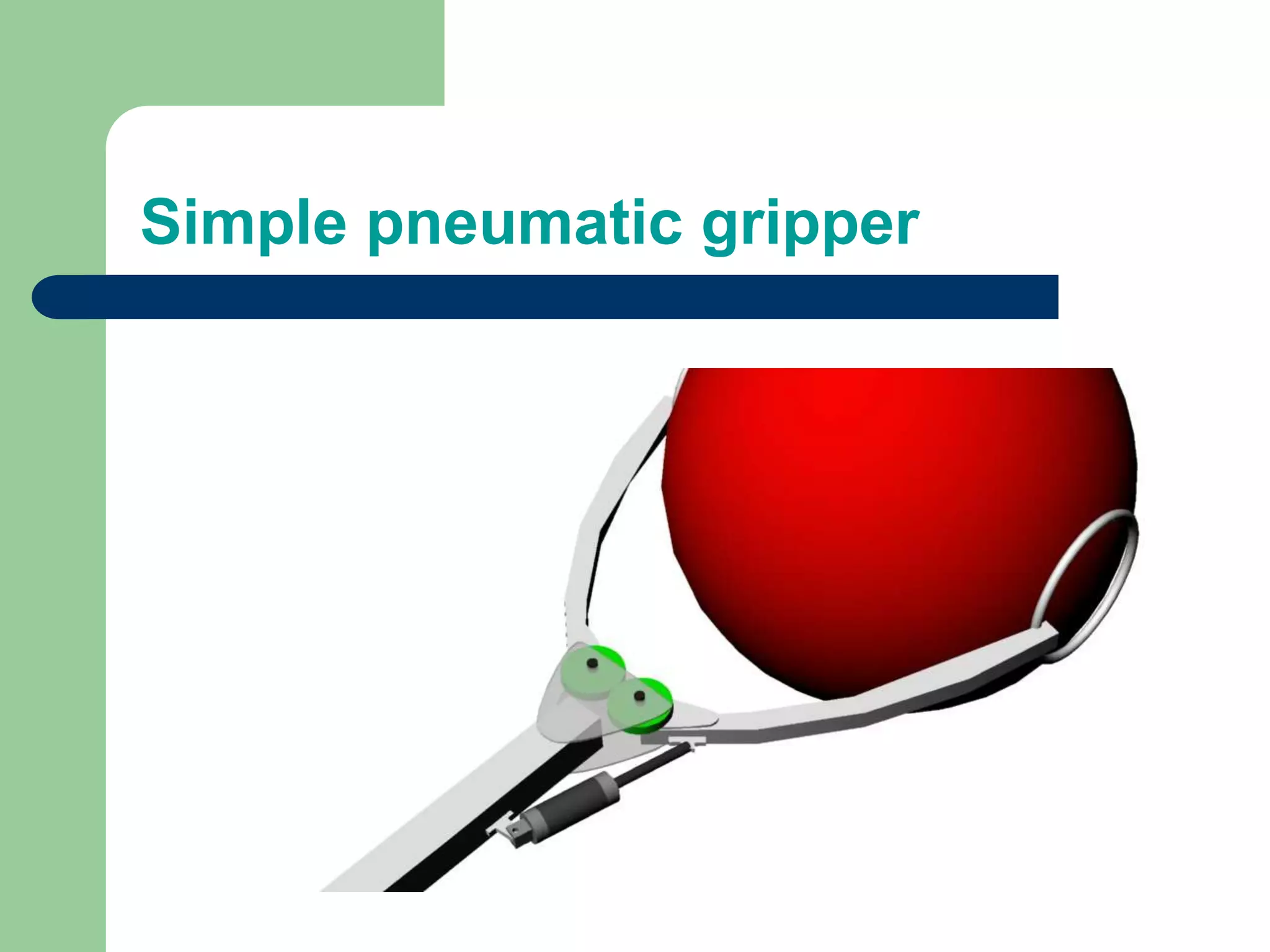

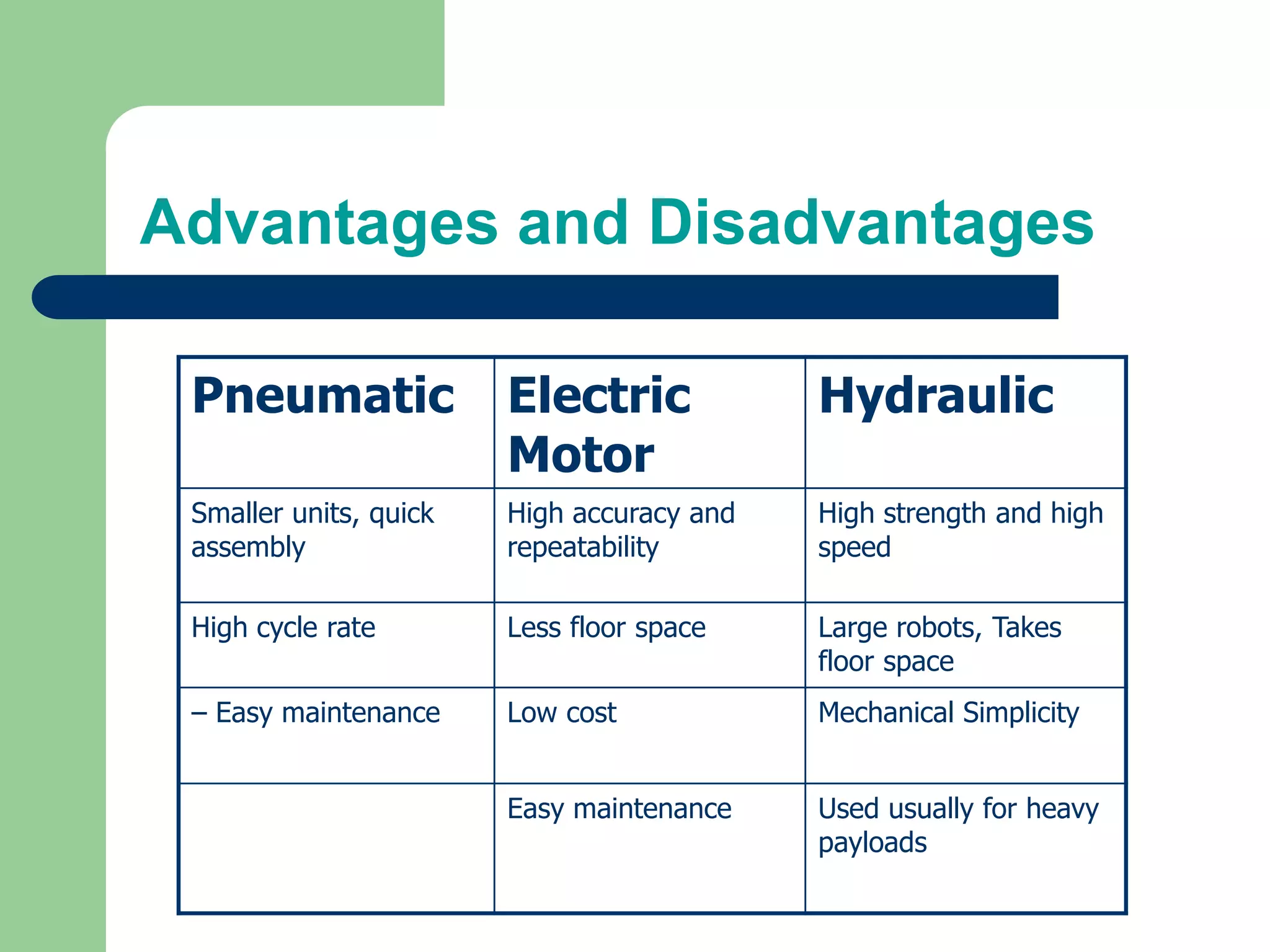

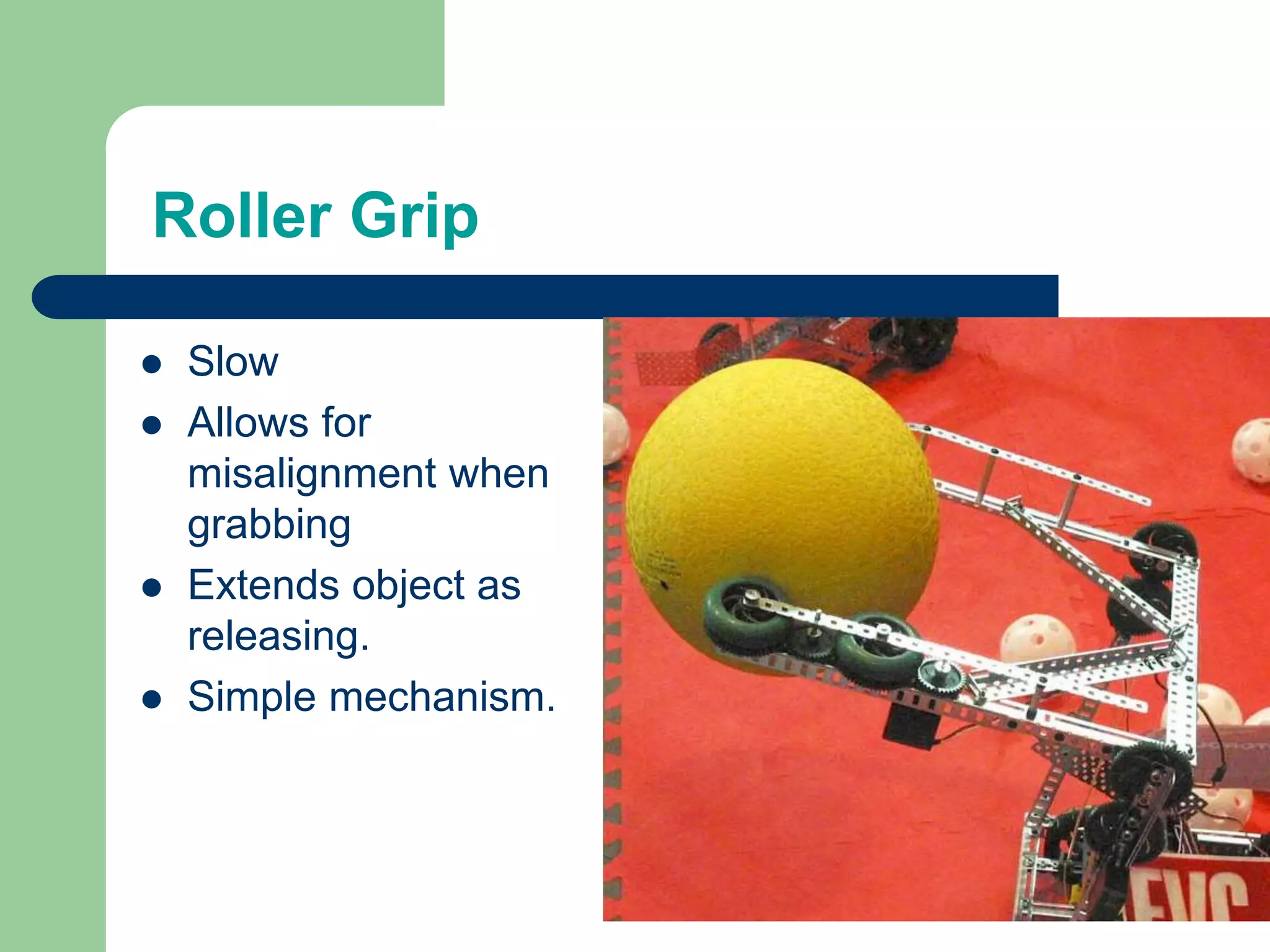

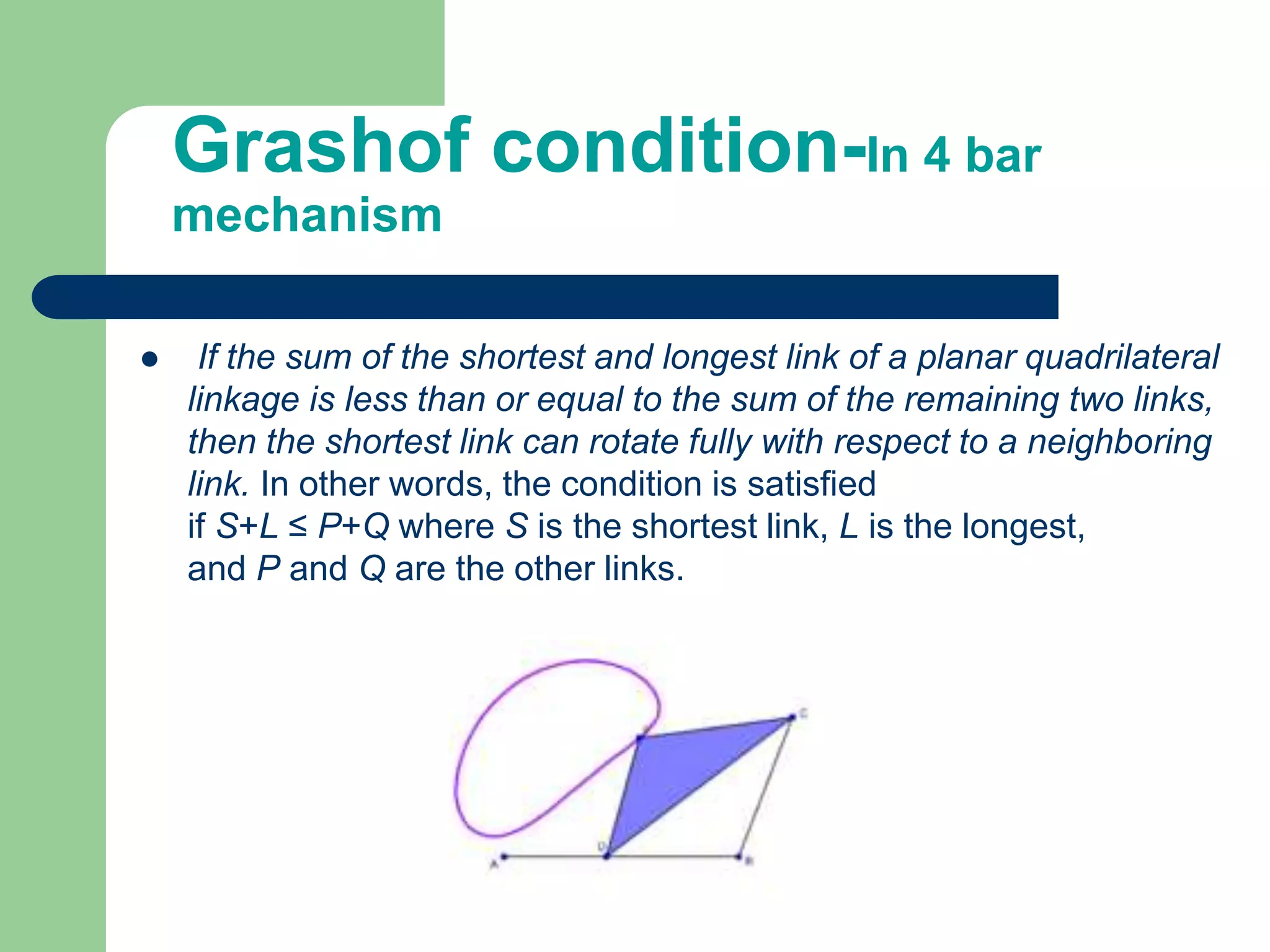

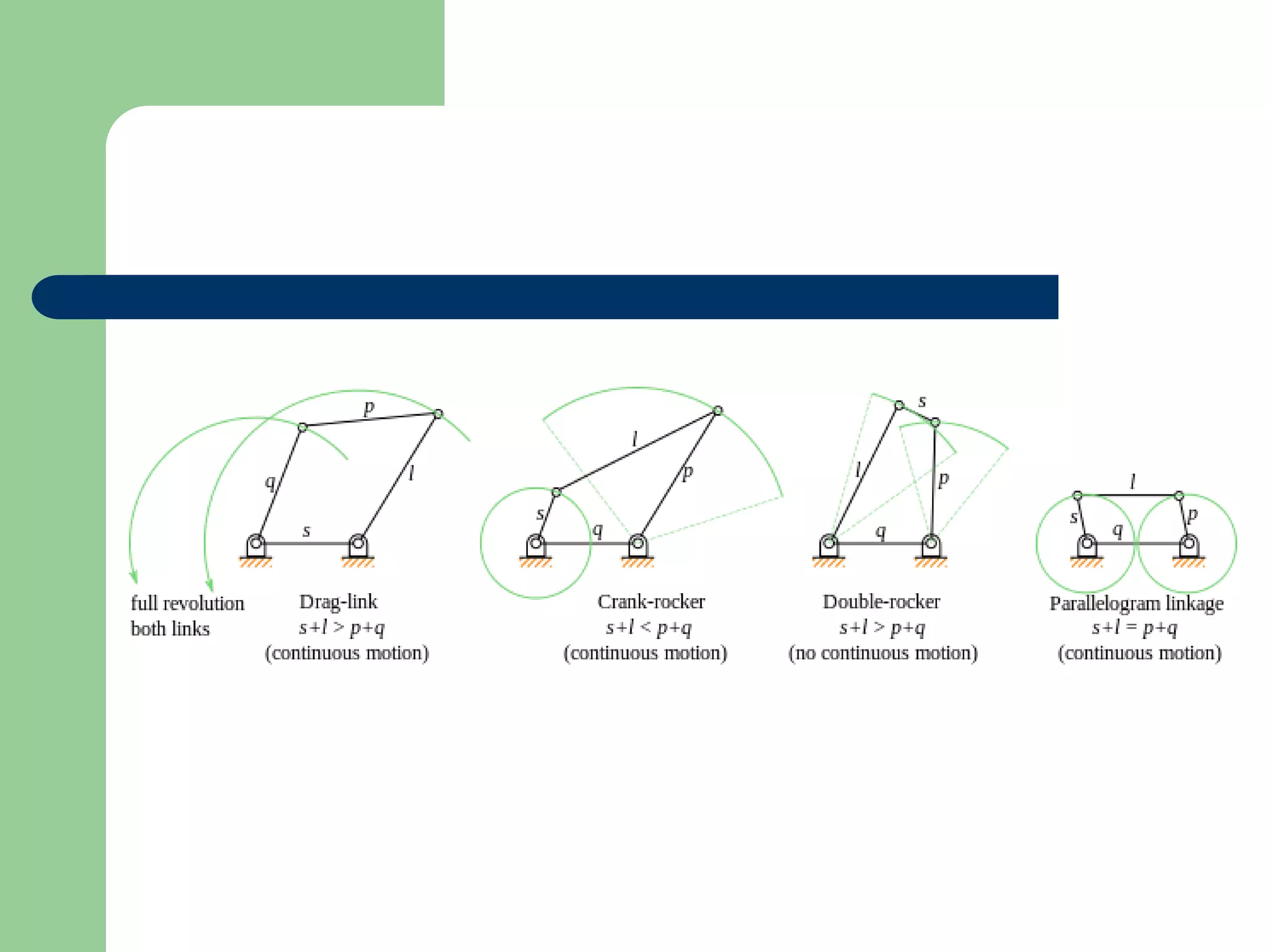

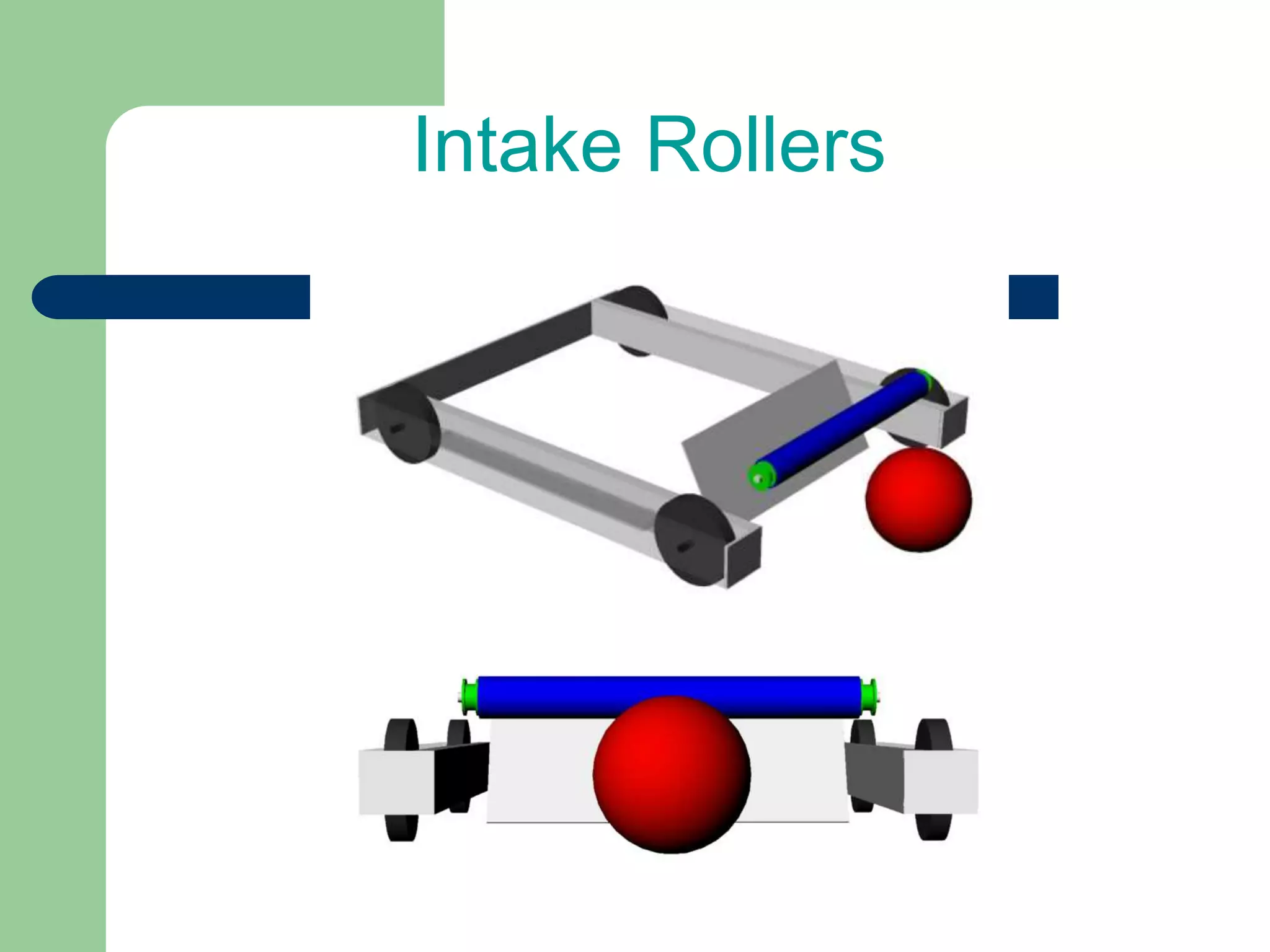

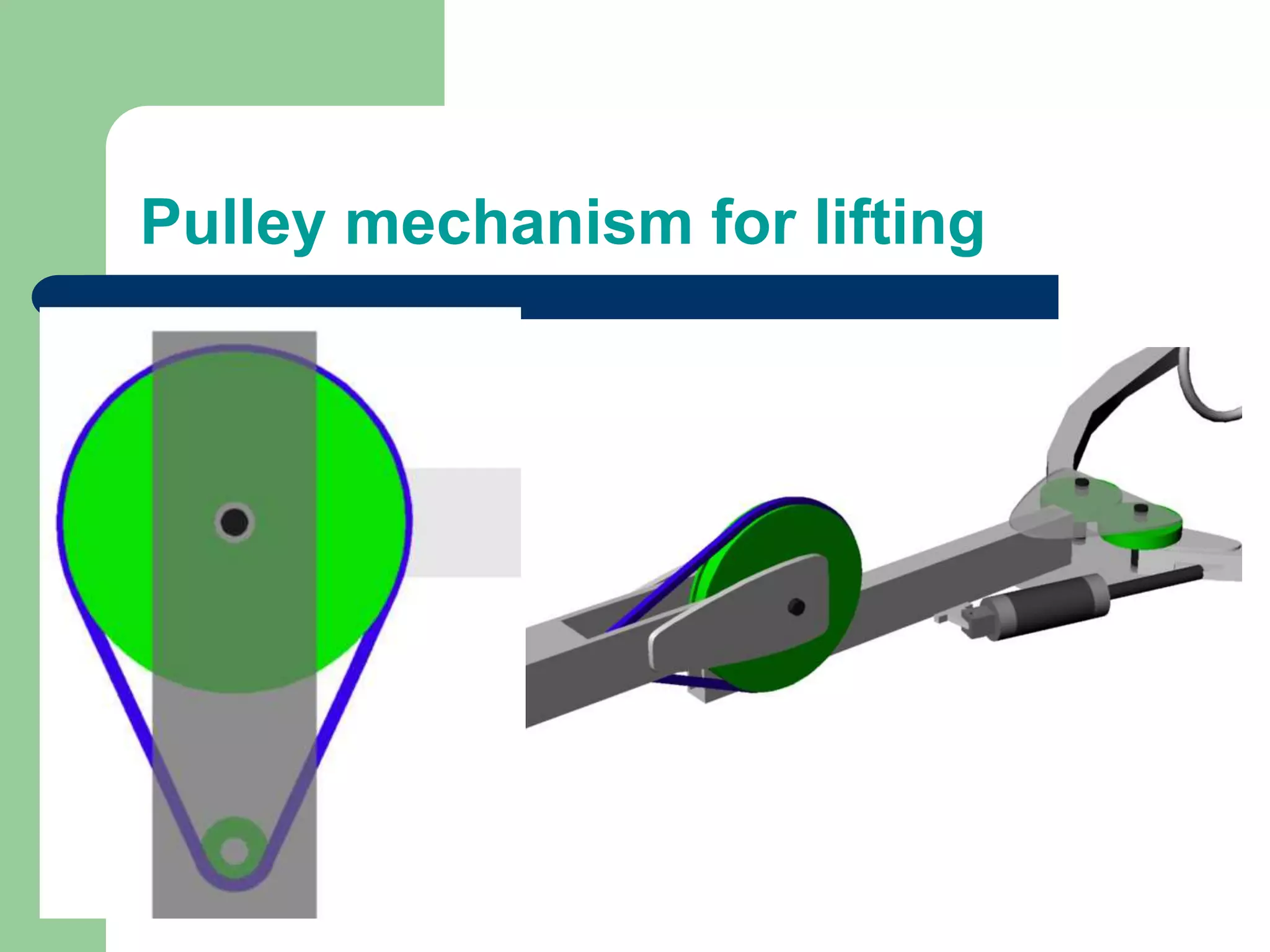

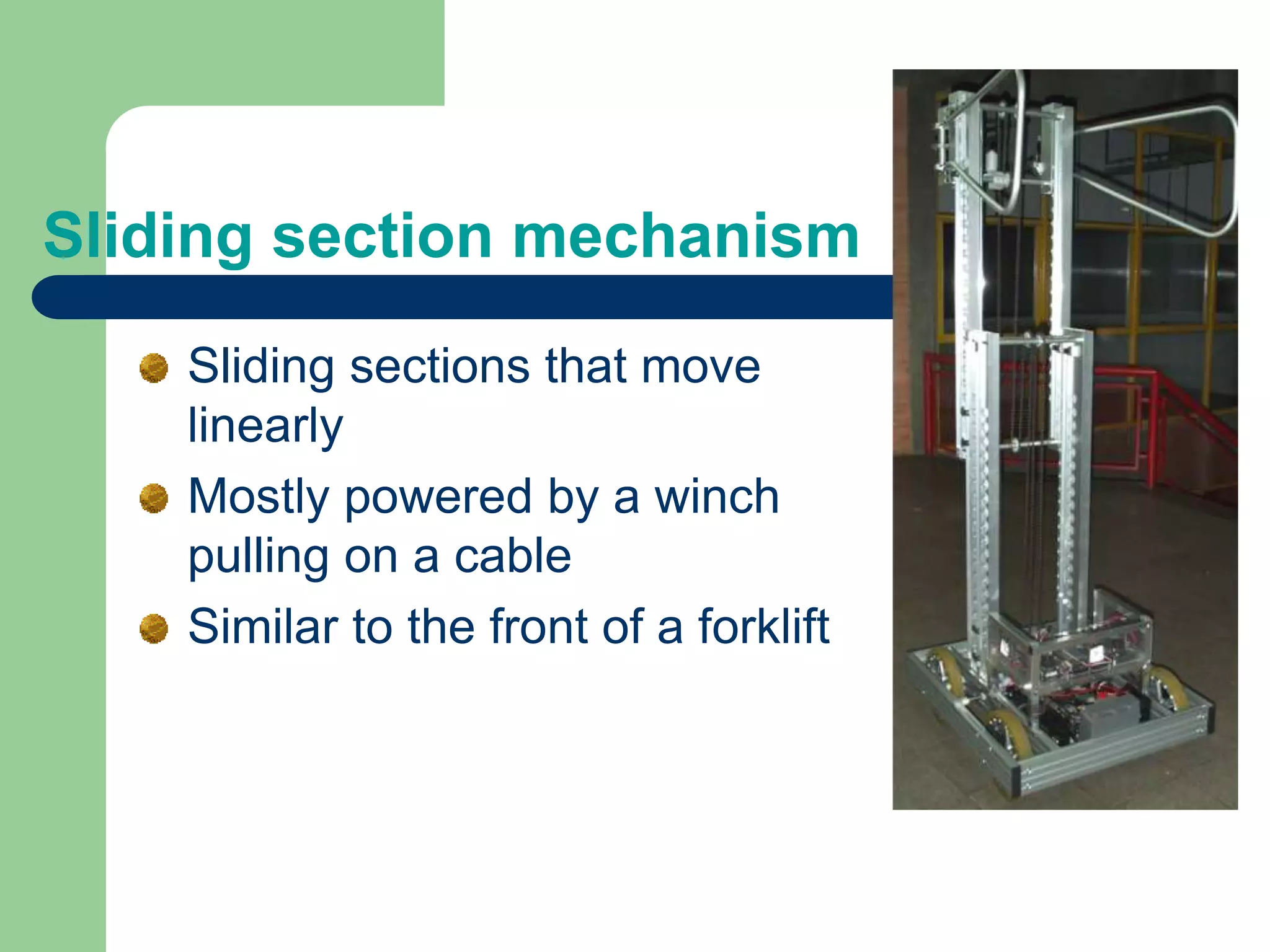

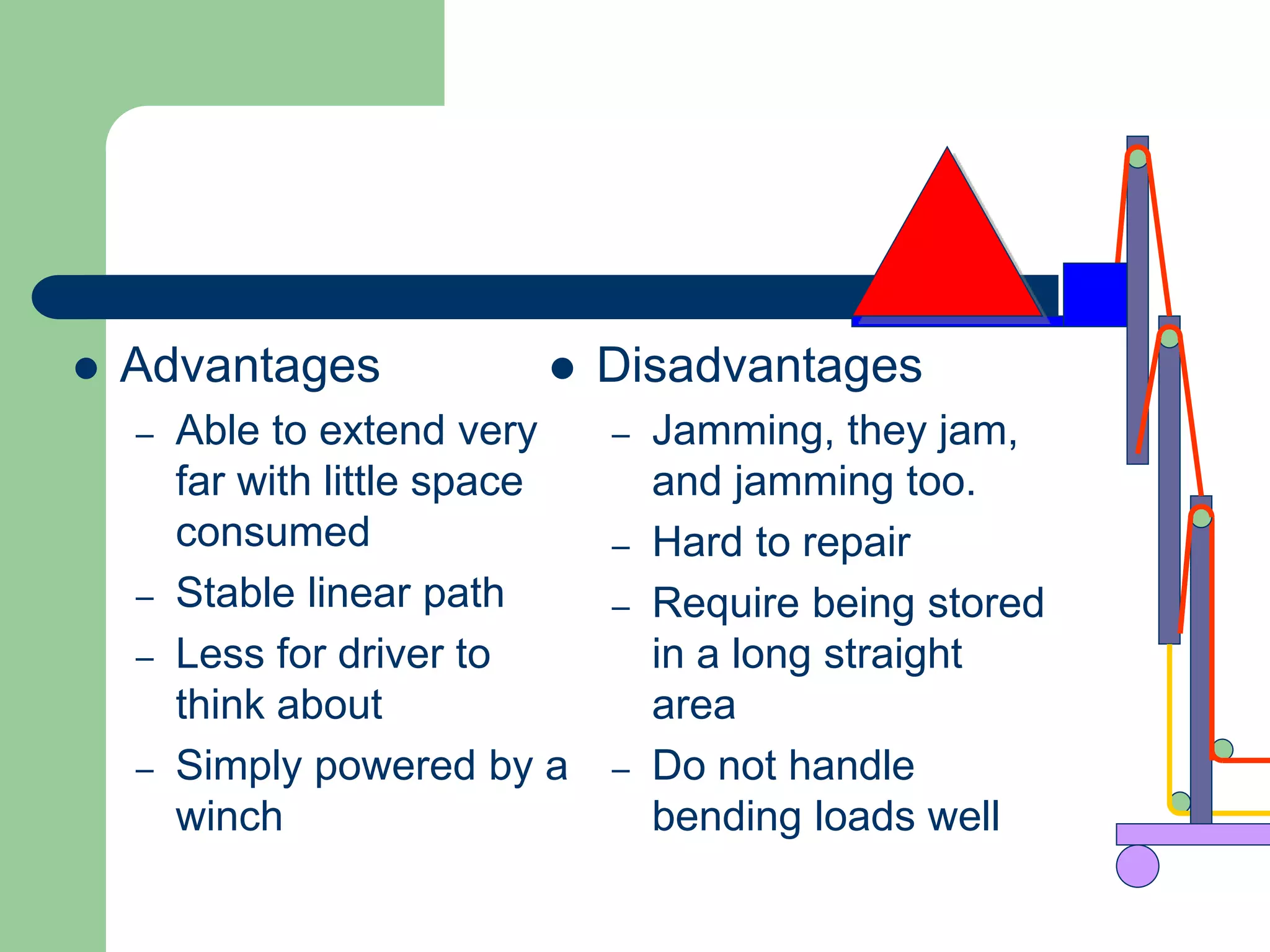

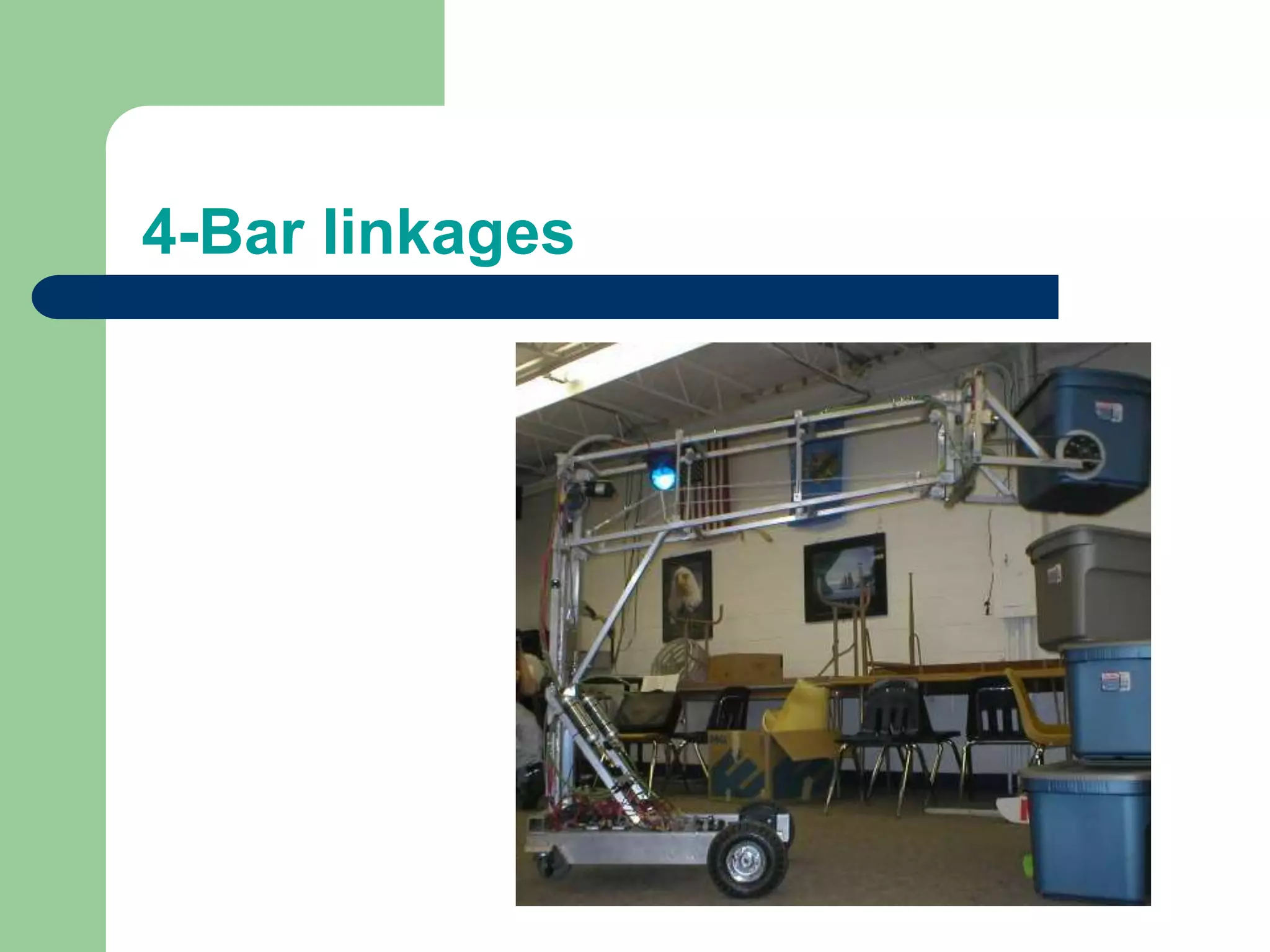

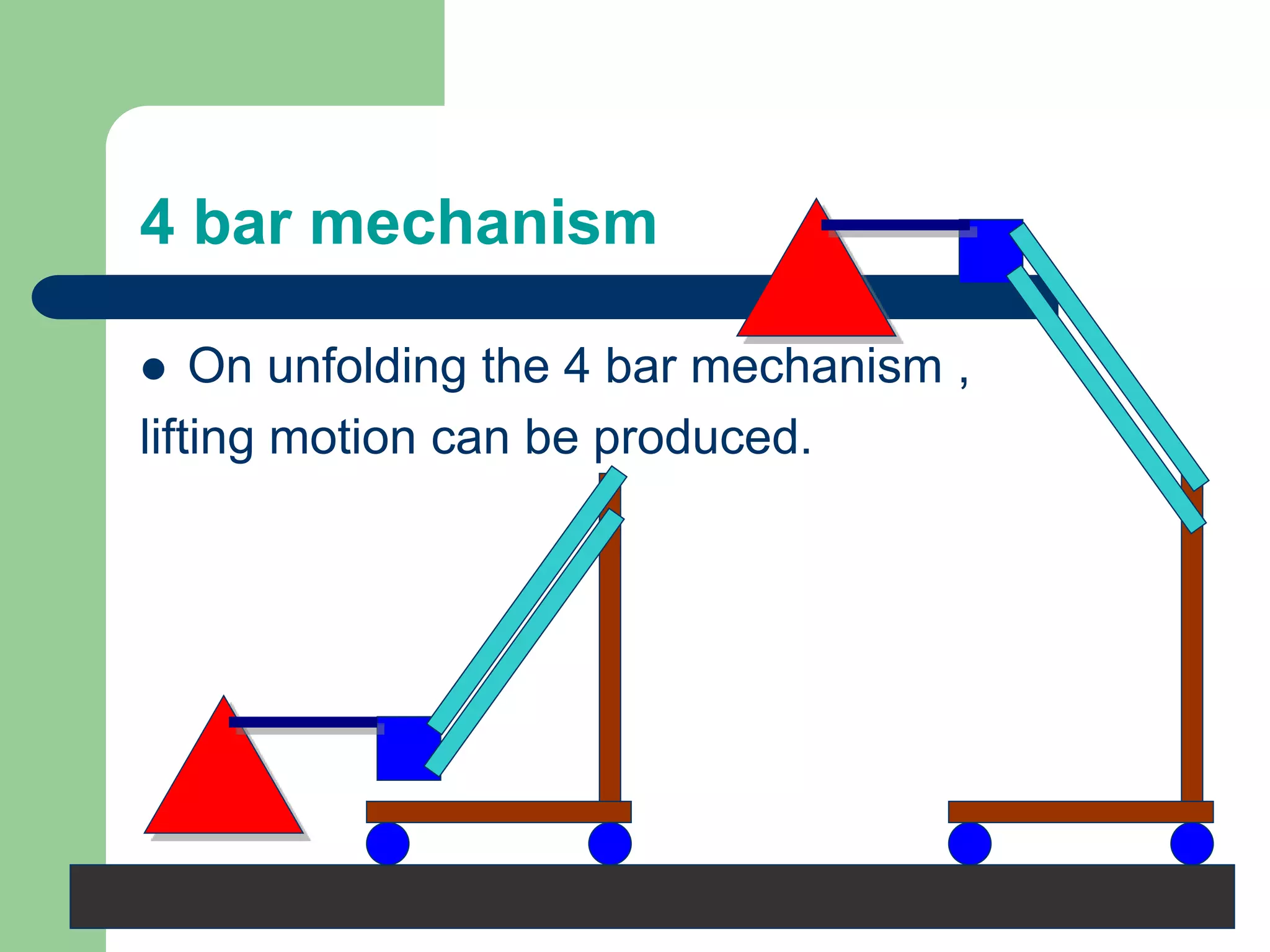

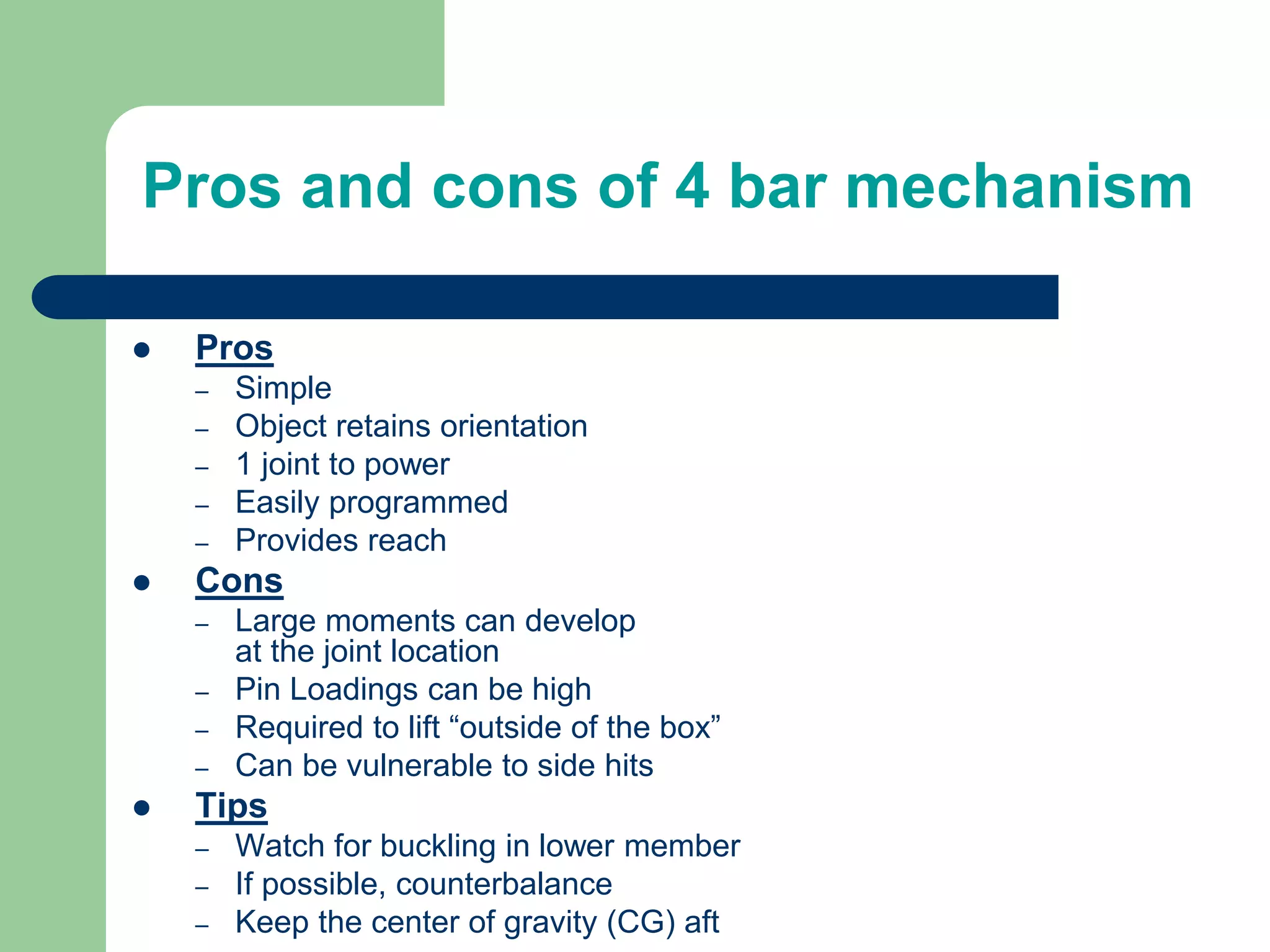

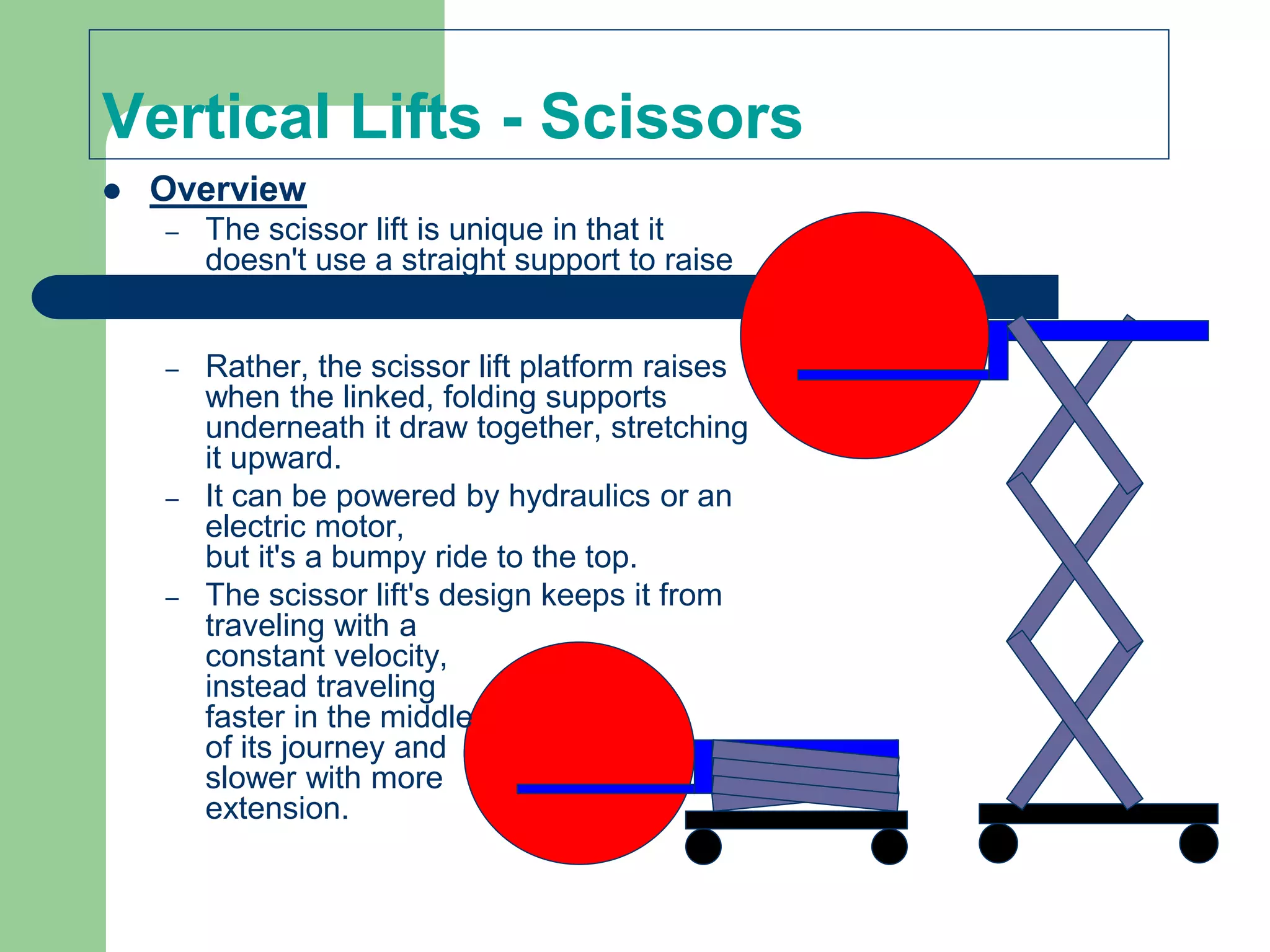

This document discusses various types of grippers and lifting mechanisms used in robotics, including vacuum grippers, parallel grippers, pneumatic grippers, roller grippers, and 4-bar linkage mechanisms. It provides details on the working, advantages, and disadvantages of each type. Scissor lifts are also summarized as using linked, folding supports to lift a platform in a bumpy motion that is faster in the middle of the journey than at the start and end.