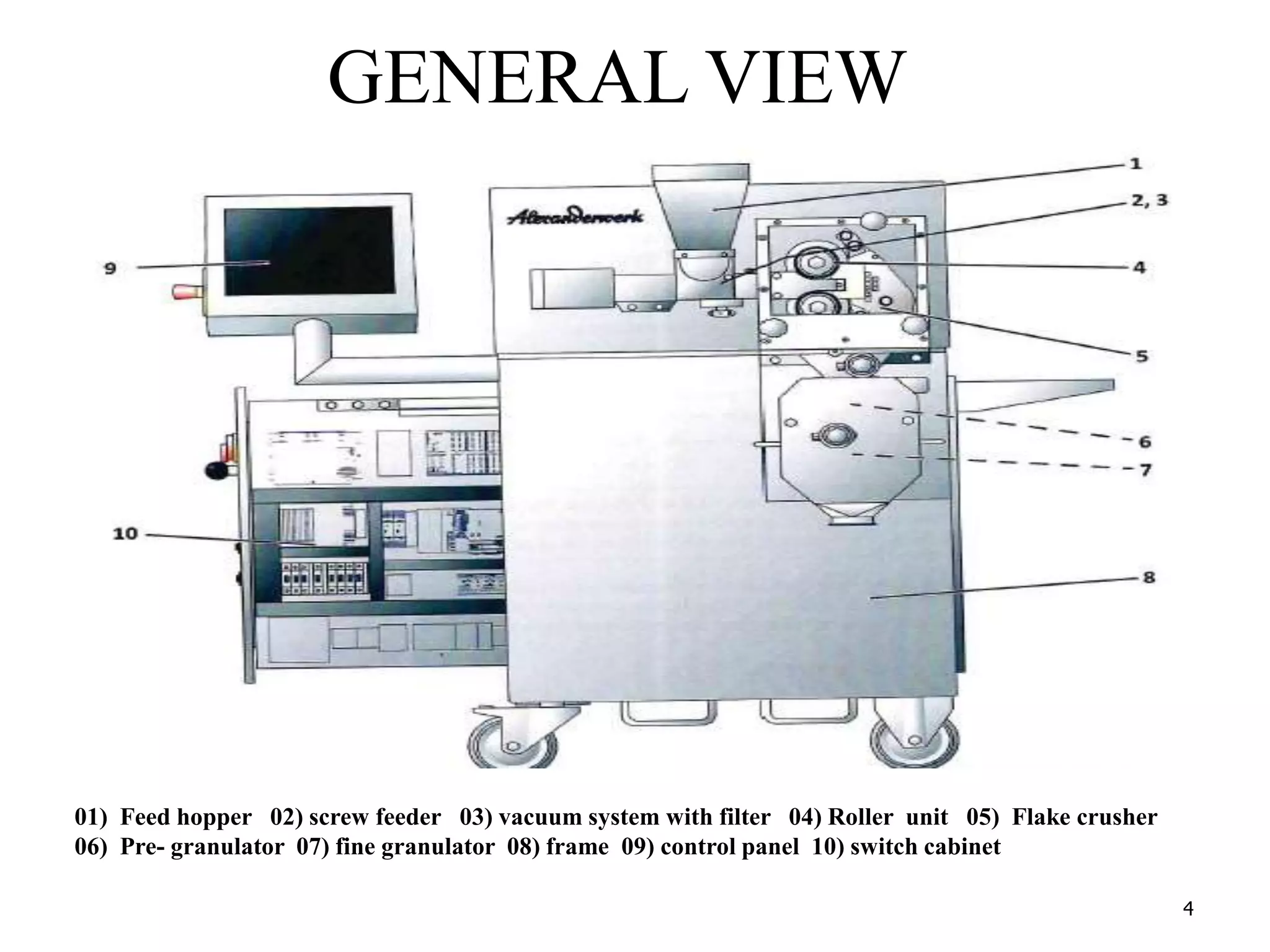

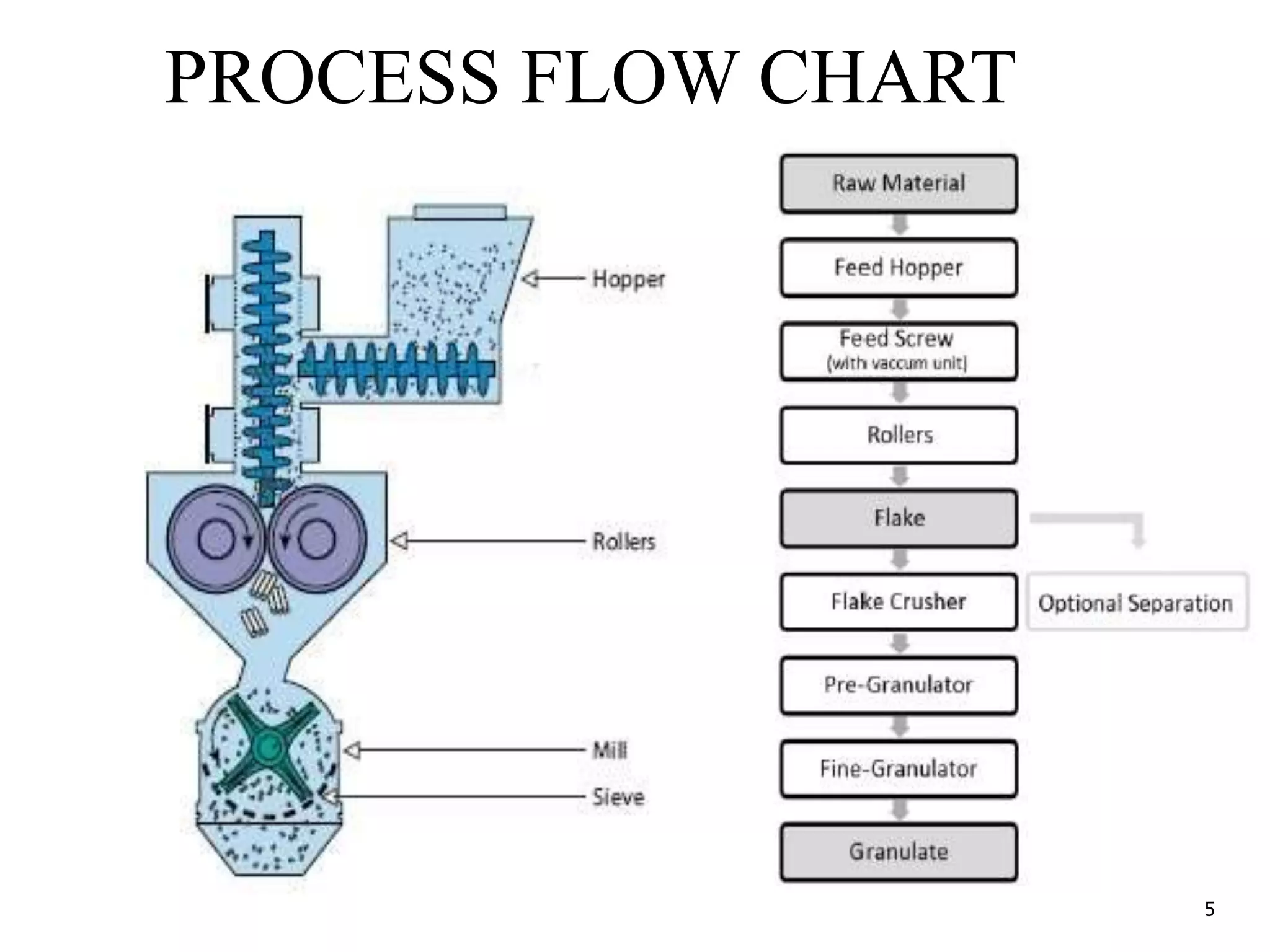

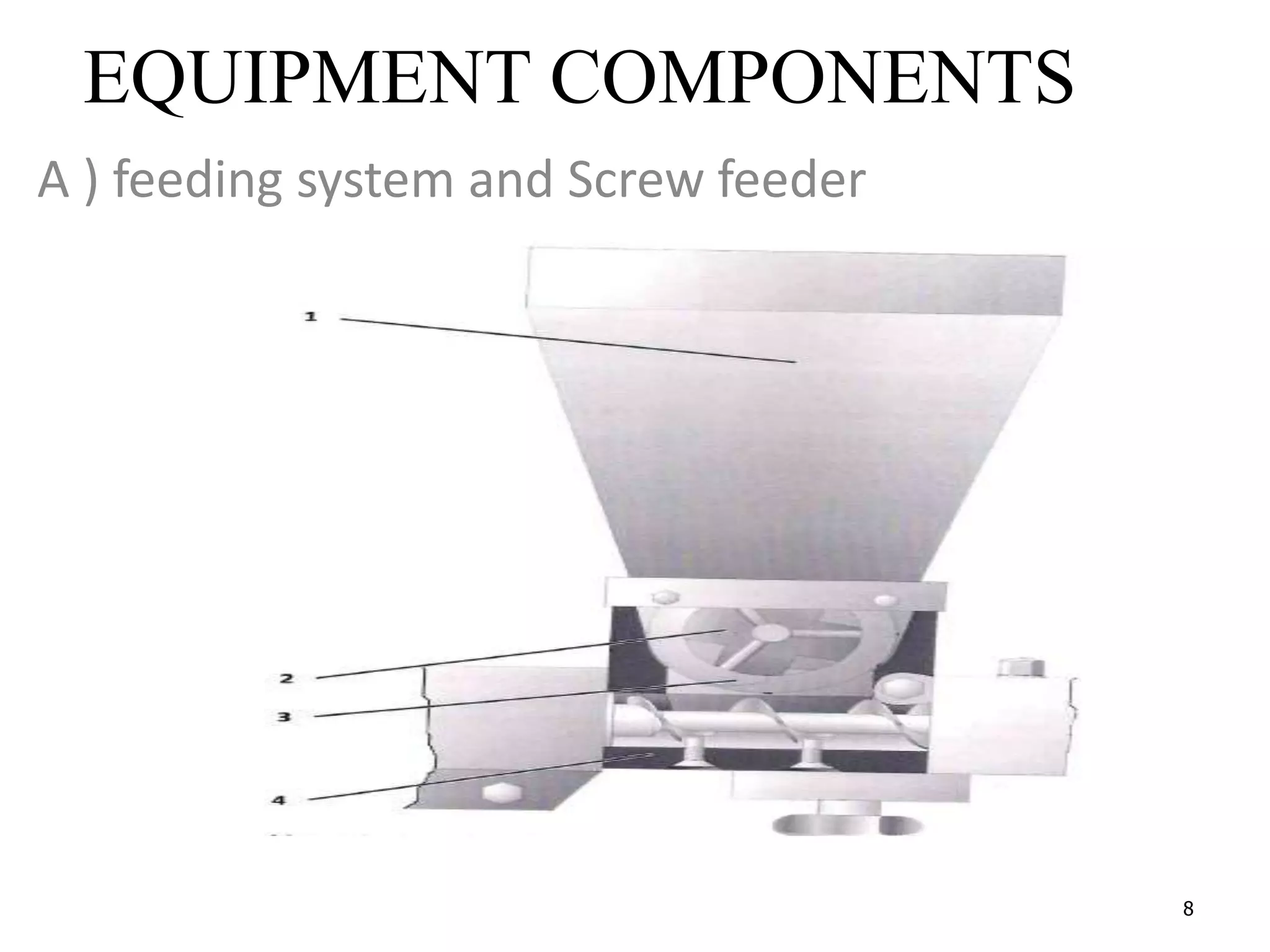

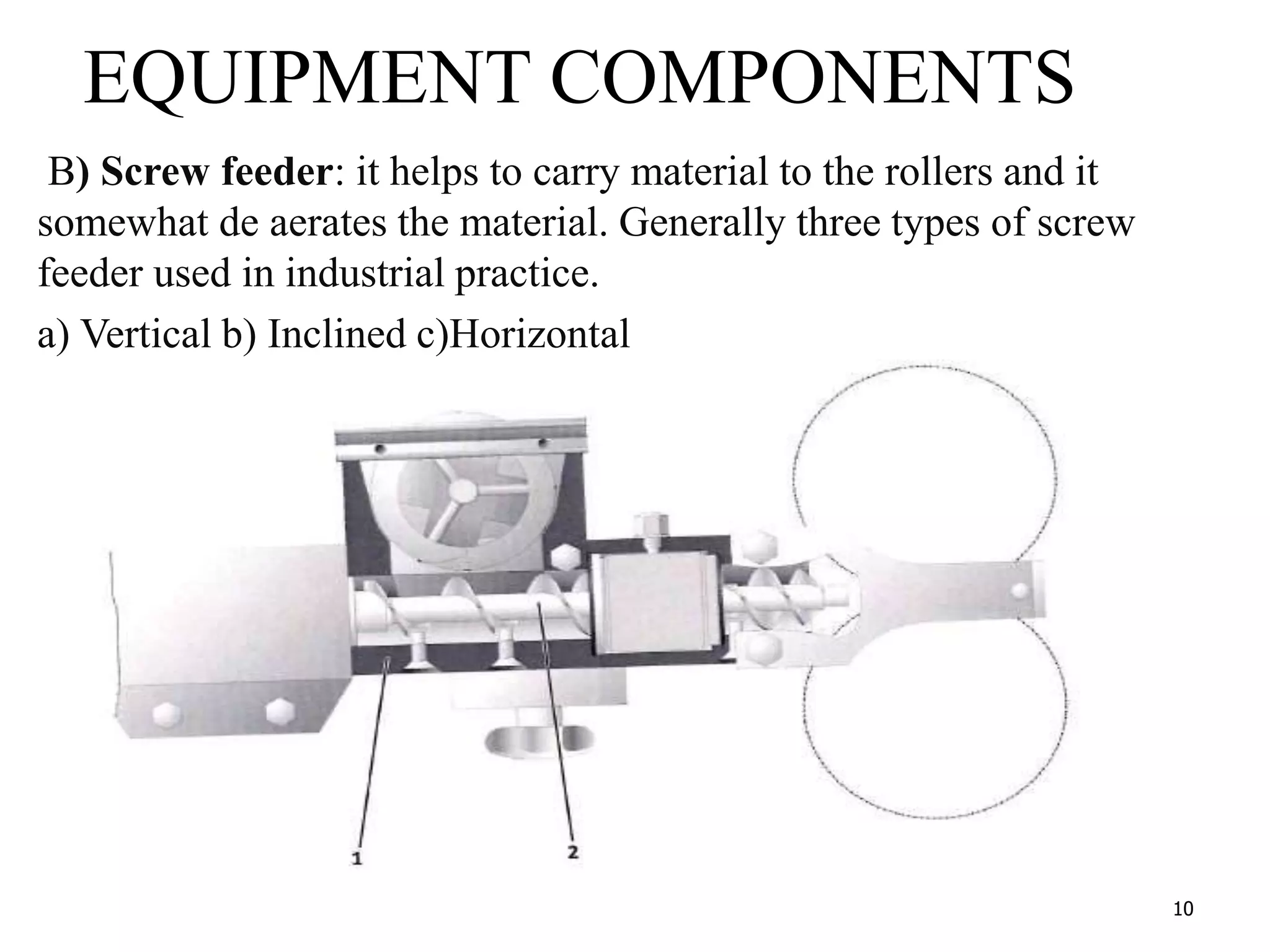

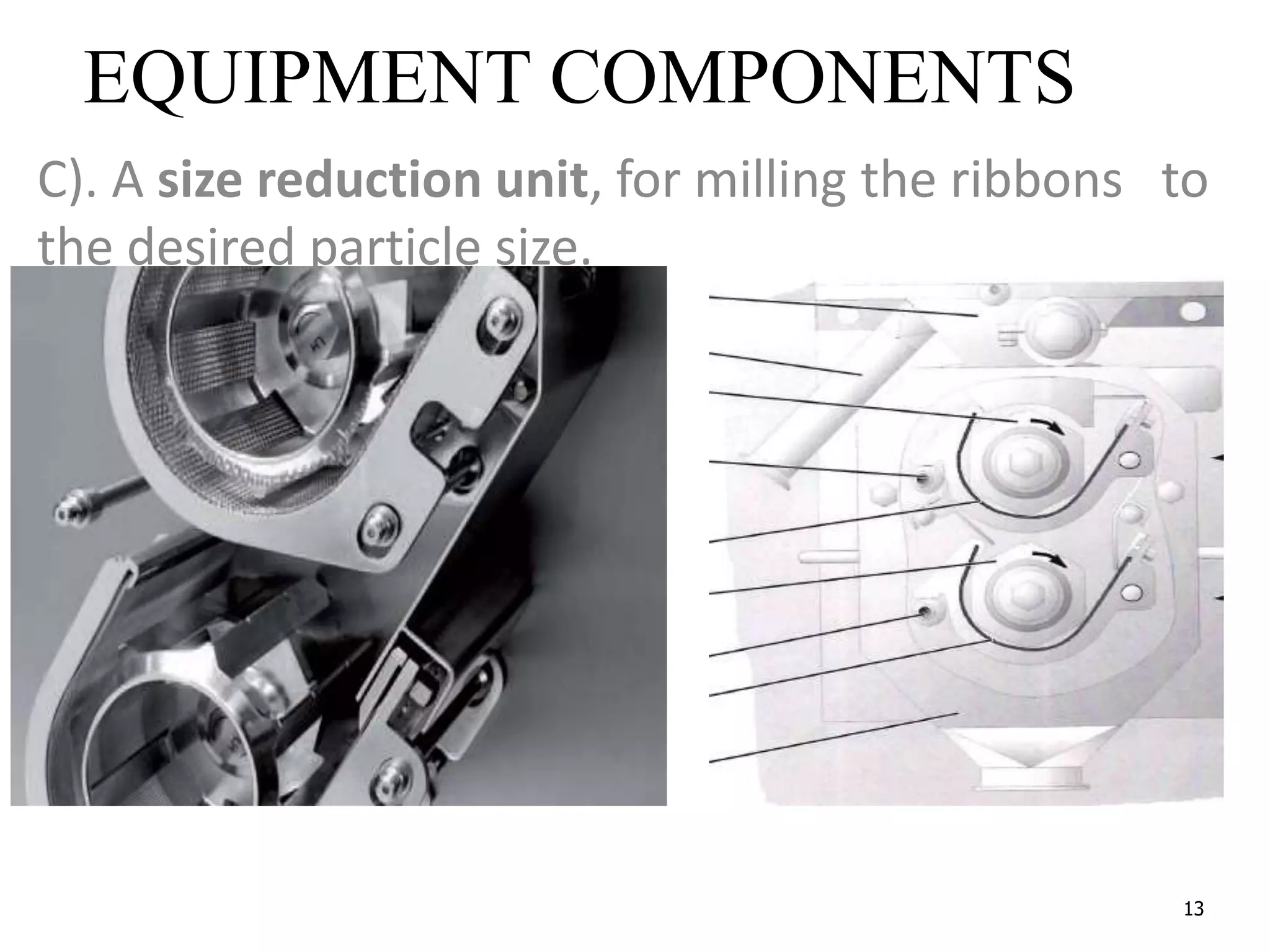

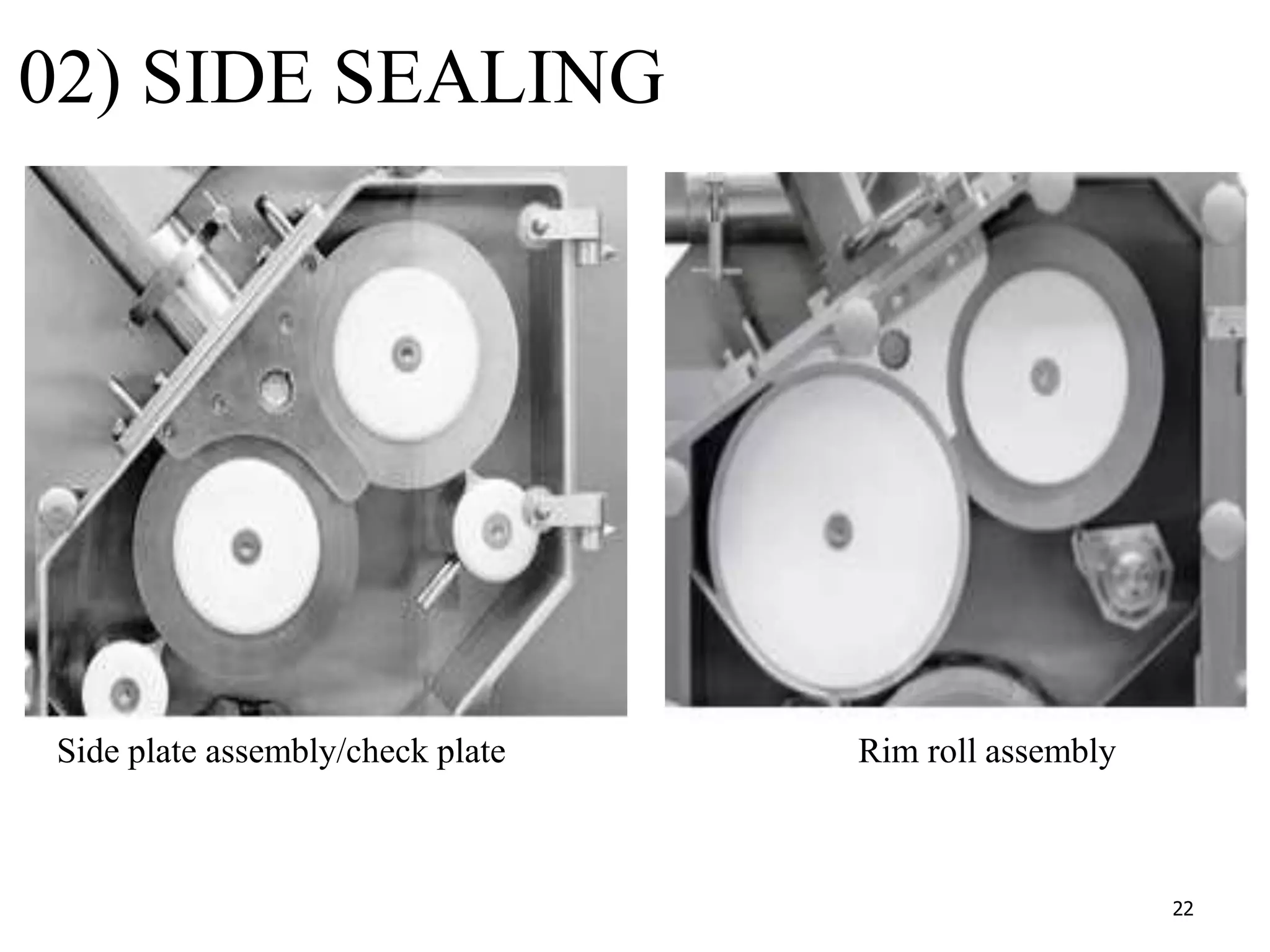

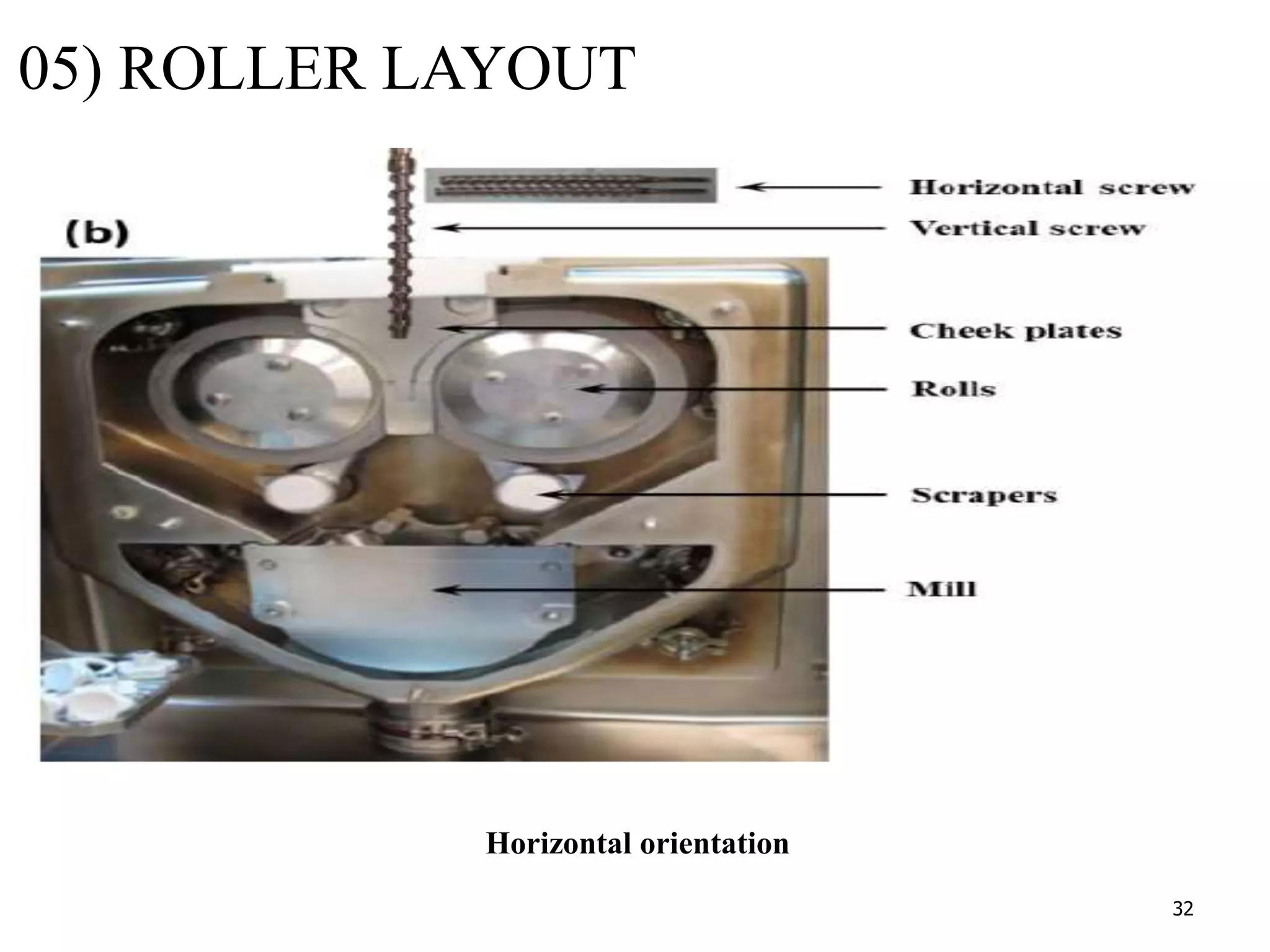

Roller compactors are used in the pharmaceutical industry to densify fine powders into solid compacts like flakes or sheets. They have replaced slugging as the preferred dry granulation method. A roller compactor consists of a feeding system, compaction unit between two counter-rotating rolls, and a size reduction unit. It provides pre-densification, improves flowability, and compresses particles into larger agglomerates quickly and efficiently. Key design considerations include the roller assembly type, side sealing method, feeding mechanism, roller surface, and roller orientation. Roller compaction offers benefits like improved flow and stability but can impact dissolution if not formulated properly.