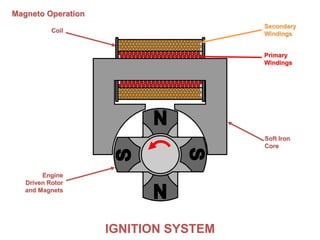

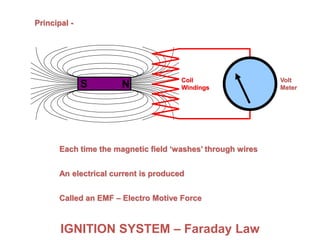

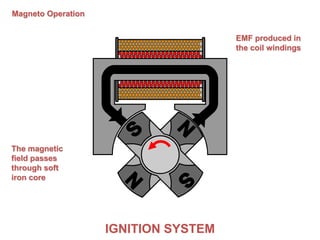

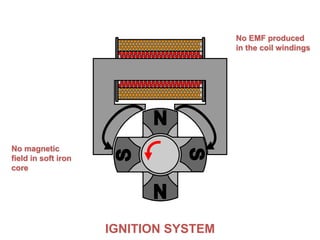

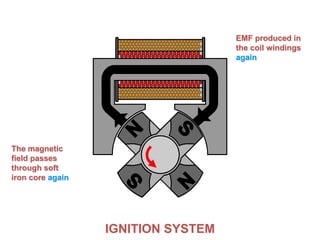

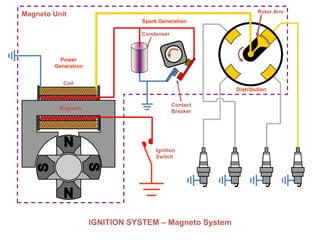

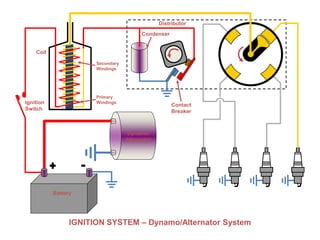

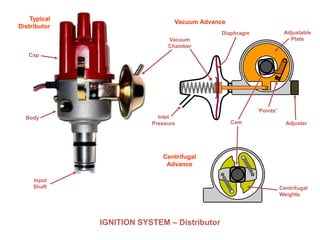

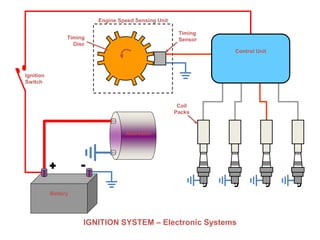

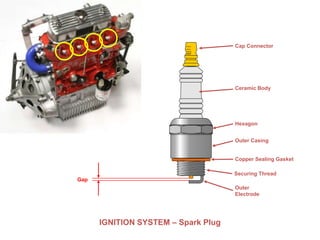

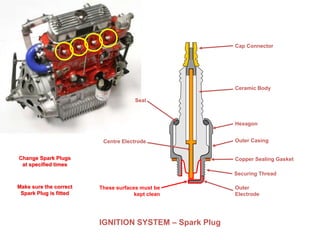

Piston engines require an ignition system to produce sparks in the combustion chambers. A magneto generates high voltage sparks through rotating magnets and coil windings. It distributes the spark to each cylinder through a distributor block. Modern systems use electronic ignition for improved timing control. Spark plugs transmit the high voltage spark across an air gap to ignite the fuel-air mixture. Proper ignition timing and regular spark plug maintenance are important for reliable engine operation.