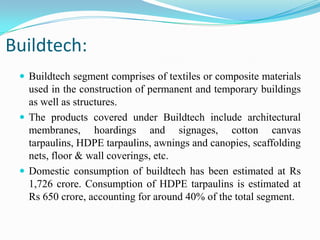

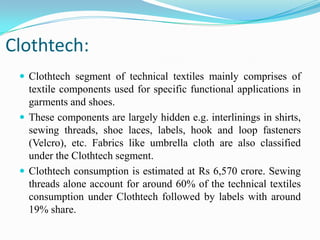

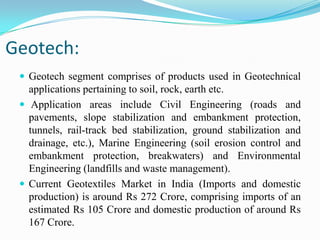

This document discusses technical textiles, including their definition, classification, markets, and applications. Some key points:

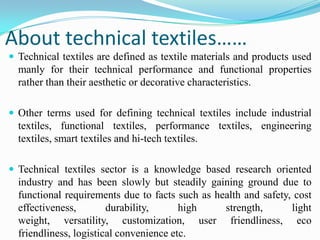

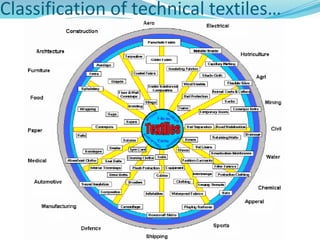

- Technical textiles are textile materials used for their functional properties rather than aesthetic qualities. They include industrial, functional, and high-tech textiles.

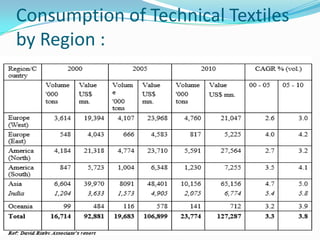

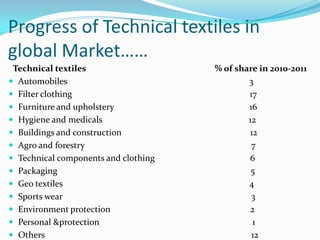

- The global technical textiles market was estimated at $107 billion in 2005, with areas like mobiltech, indutech, and sportech accounting for 56% of consumption. Asian countries like China and India are major markets.

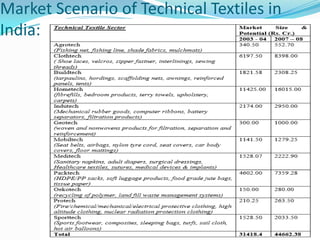

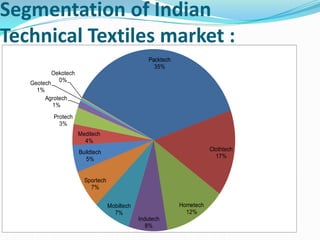

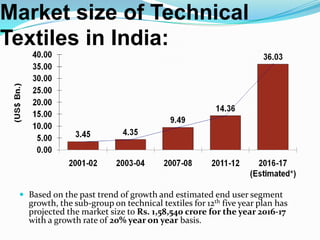

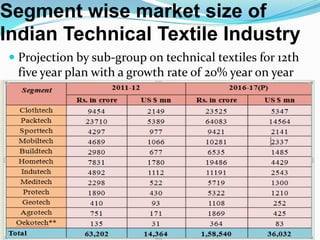

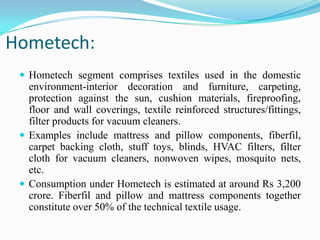

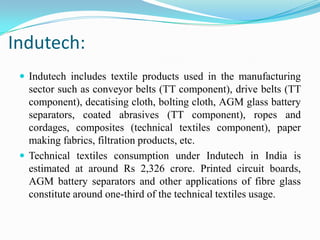

- In India, the technical textiles market was projected to reach $158 billion by 2016-17, with major segments being packtech, clothtech, hometech, and indutech.

- Technical

![References:

1. Hand book of technical textile.

2.A study of Technical Textiles- scope and classification-TE

online.com

3. Texsummit 2007

4. G Kamatchi and S. K.Bala, Asian Textile Journal, 15 (11) [2006]

63.

5. Widen raw material base, The Indain Textile Journal, January 2010

viewpoint [2009].

6. Colourage march 2013 page no 85-90

7. fibre2fashion.com

8. google.com

9. Colourage march 2013 page no 91-96

10.Man-made textiles in India July-2010, page-no,241-249

11.indiantextilejournal.com/articles/FAdetails](https://image.slidesharecdn.com/introductiontotechnicaltextiles3-130902125456-phpapp01/85/Introduction-to-technical-textiles3-40-320.jpg)