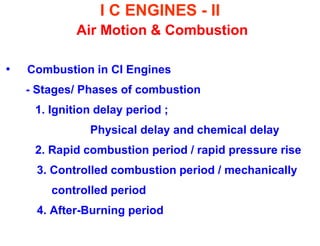

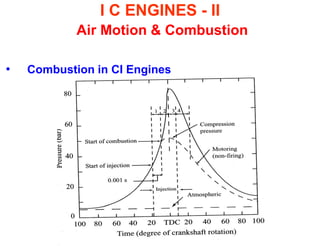

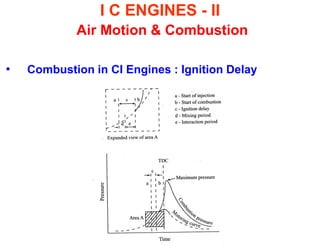

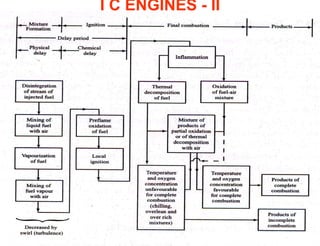

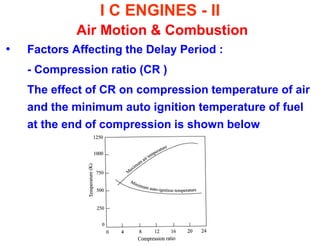

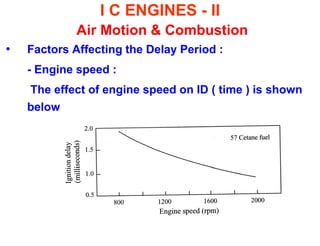

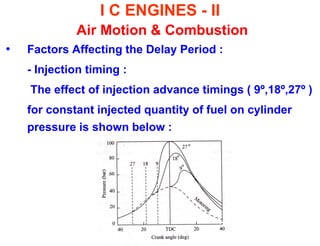

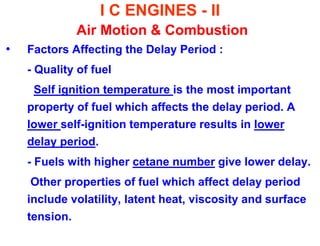

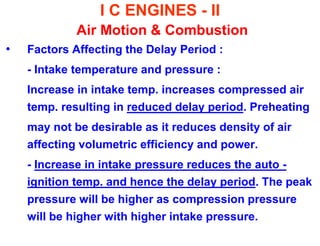

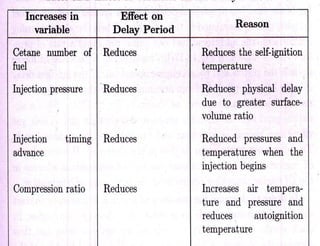

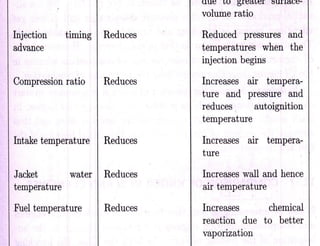

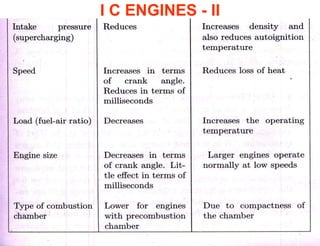

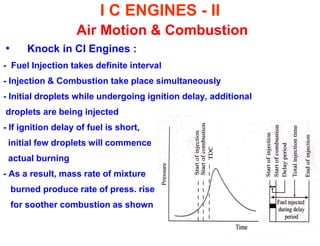

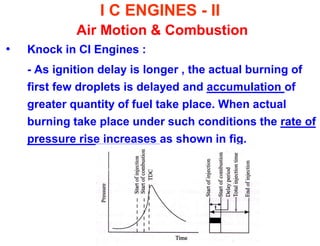

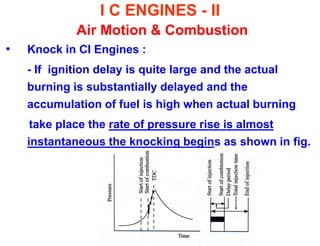

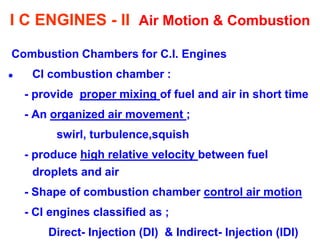

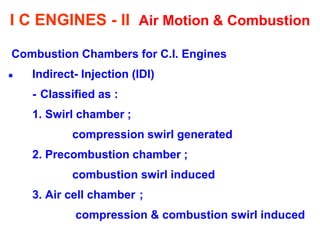

The document discusses combustion in diesel engines. It describes the four stages of combustion: ignition delay period, rapid combustion period, controlled combustion period, and after-burning period. It explains factors that affect the ignition delay period such as compression ratio, engine speed, fuel quality, and intake conditions. The document also discusses knock in diesel engines and different combustion chamber designs for diesel engines, including direct injection and indirect injection types.