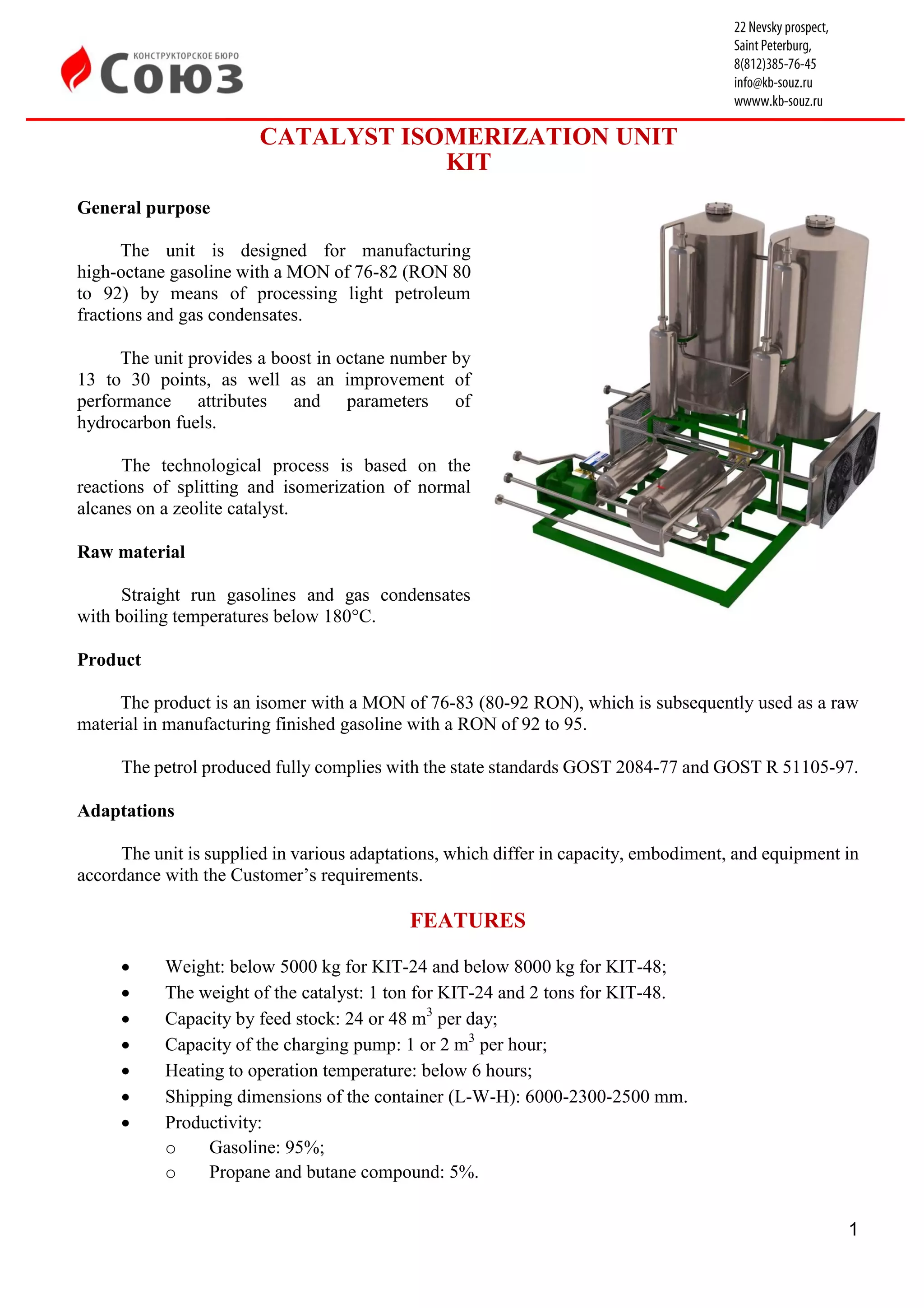

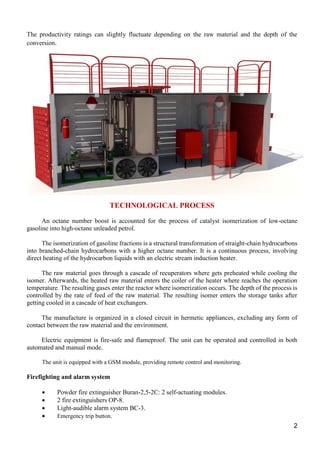

The document describes a catalytic isomerization unit (KIT) that increases the octane rating of gasoline. It processes light petroleum fractions to produce gasoline with an octane number of 76-83. The technological process involves reacting normal alkanes over a zeolite catalyst to isomerize the hydrocarbons. The unit is available in capacities of 24 or 48 cubic meters per day and can boost octane by 13 to 30 points. It operates continuously to convert low-octane gasoline into high-octane unleaded petrol.