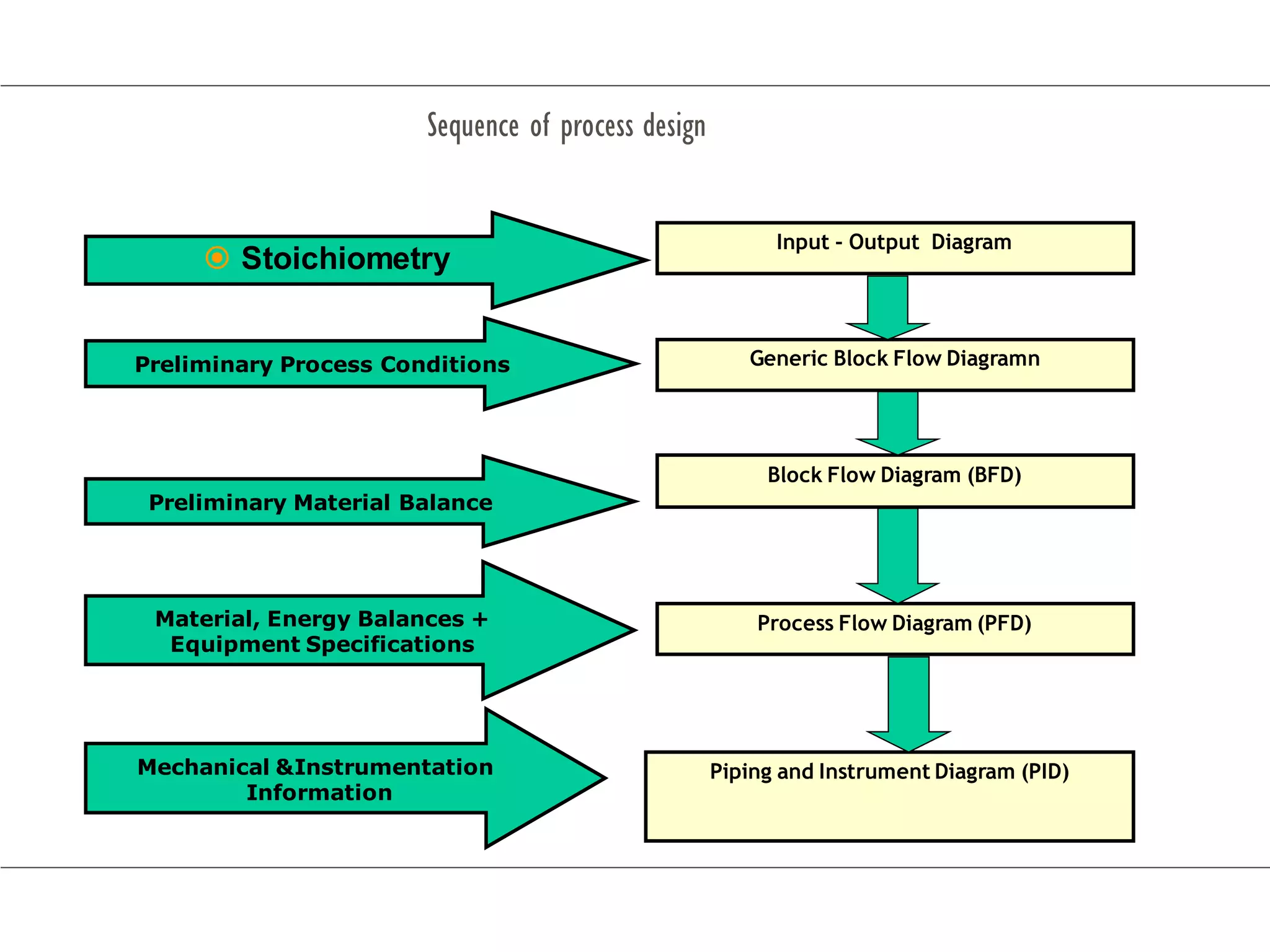

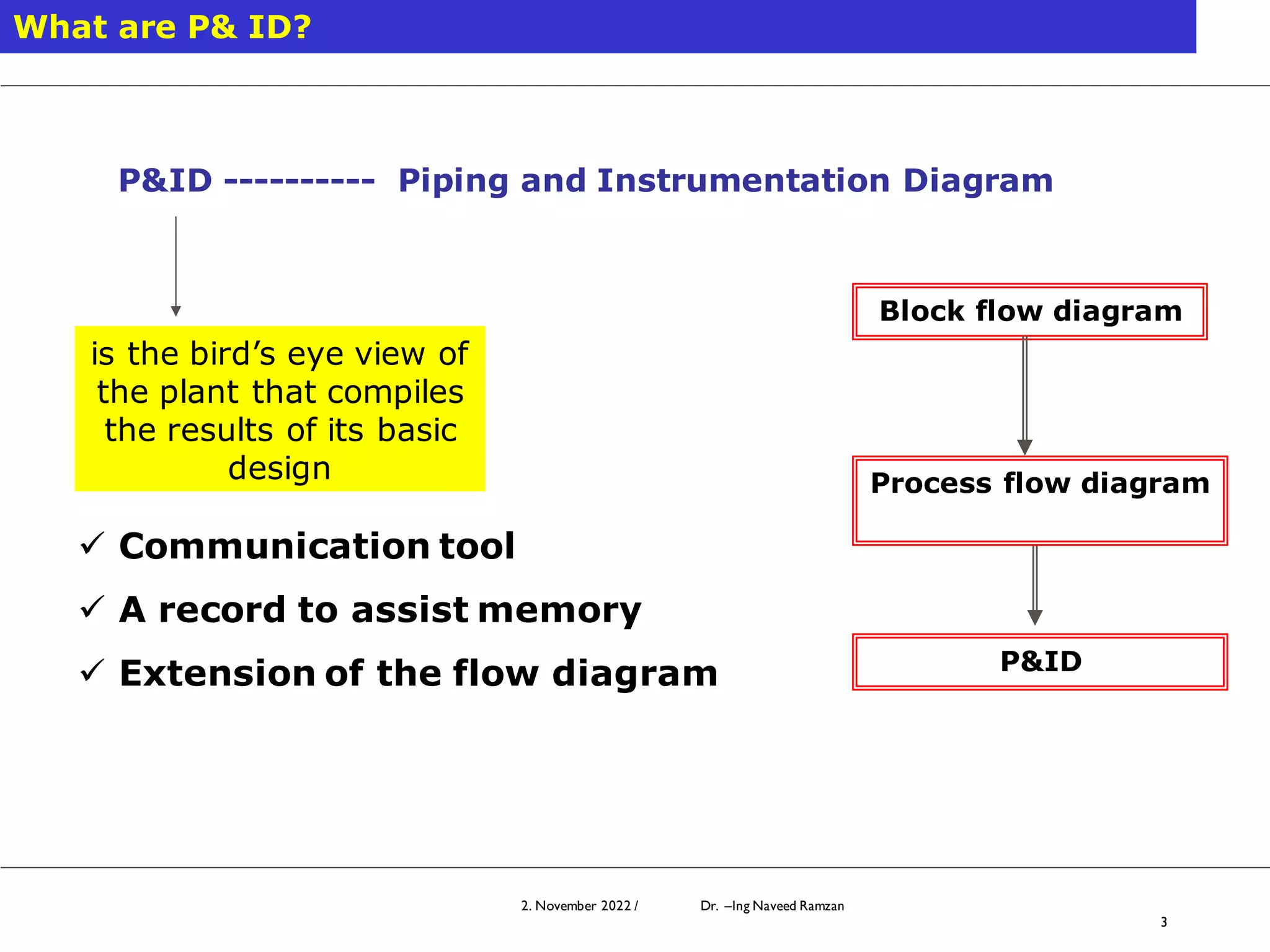

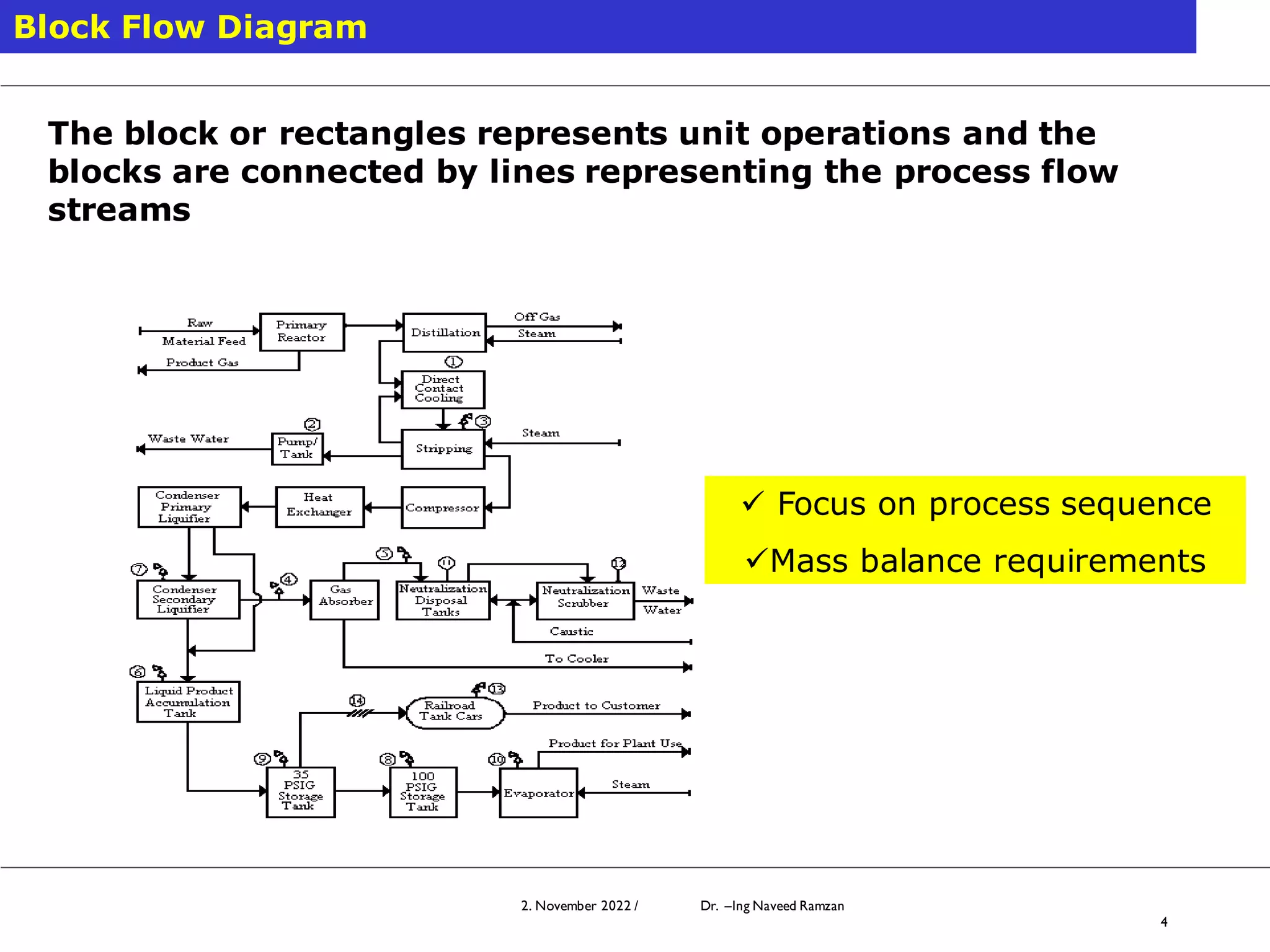

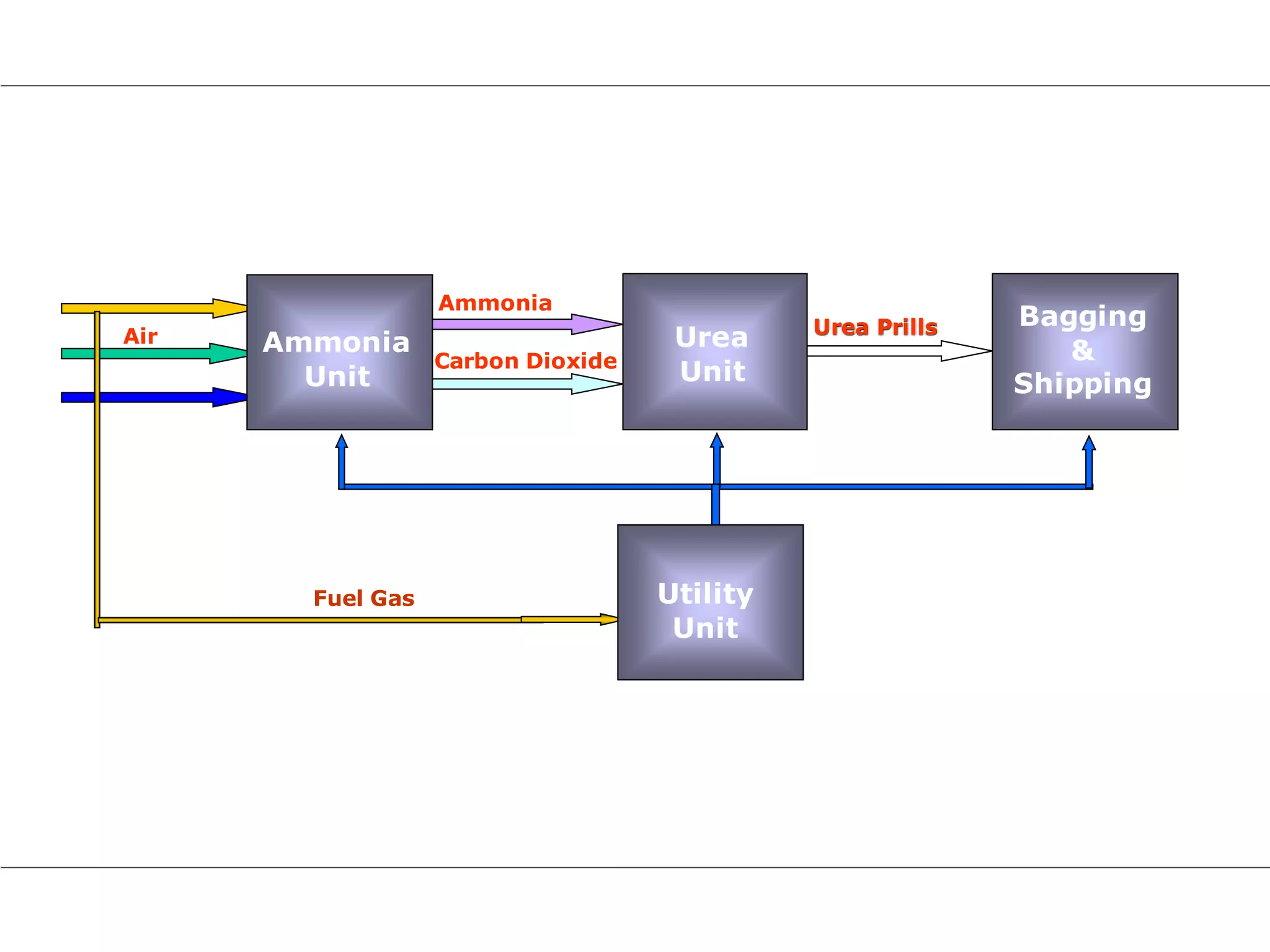

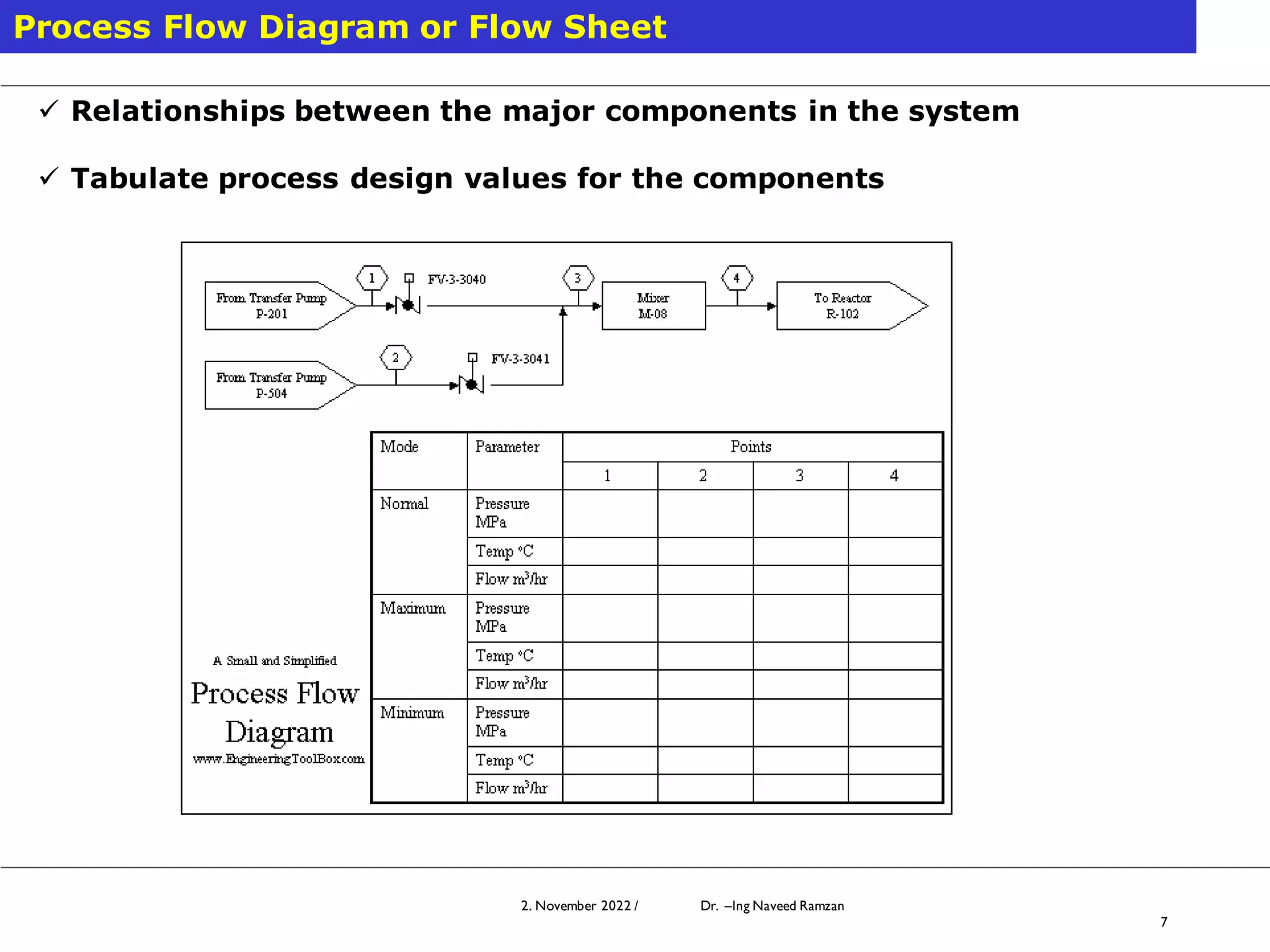

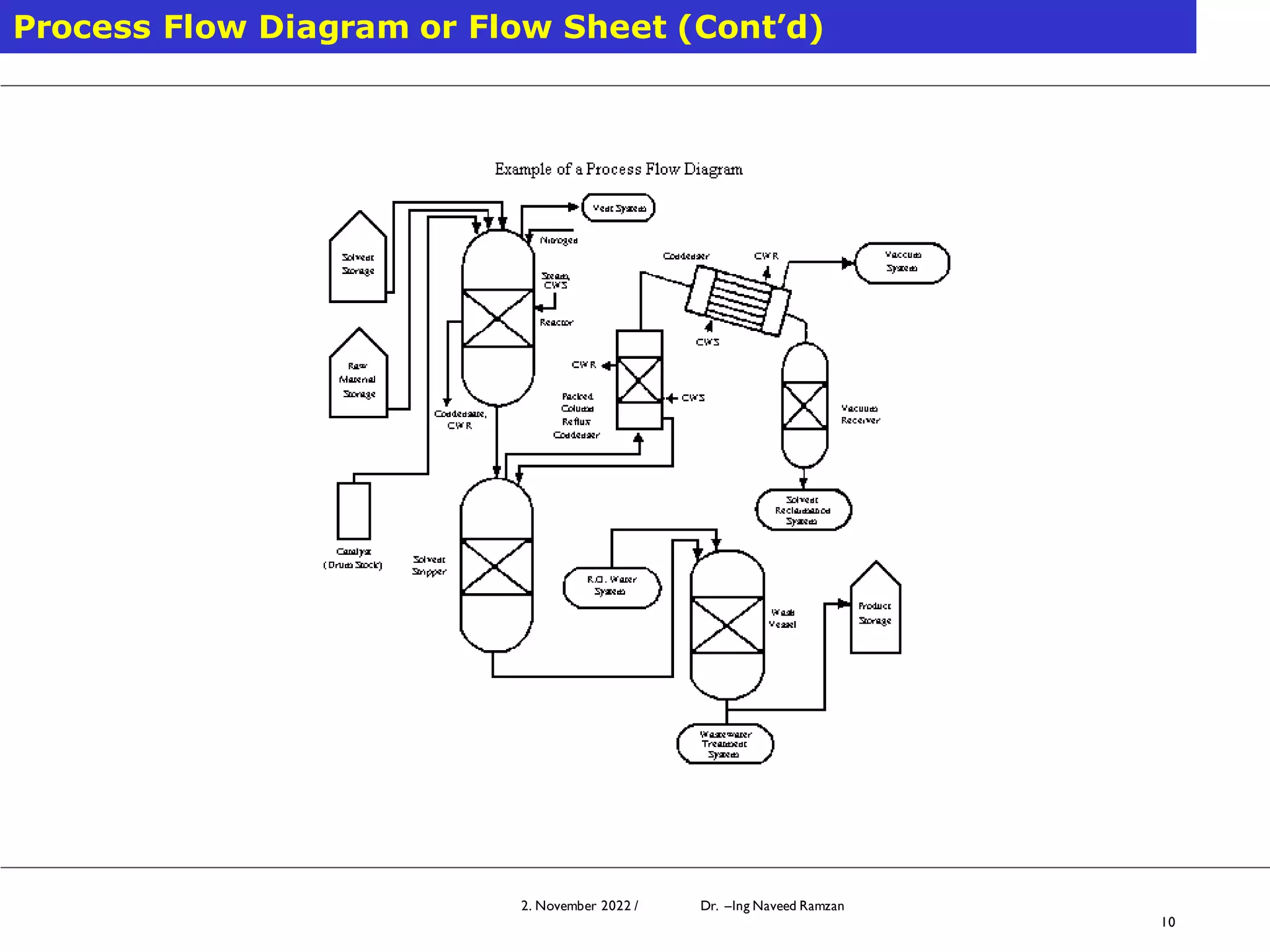

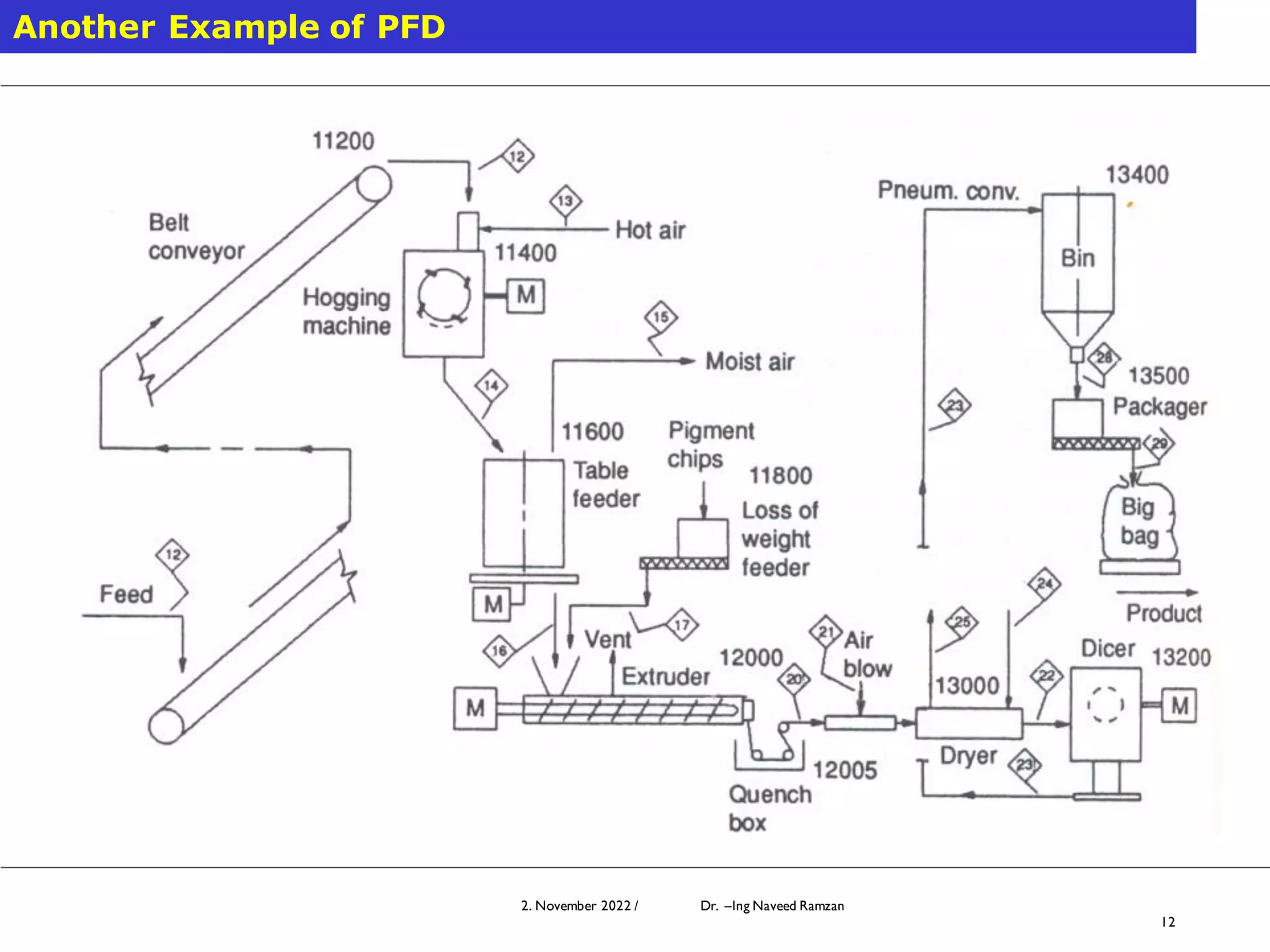

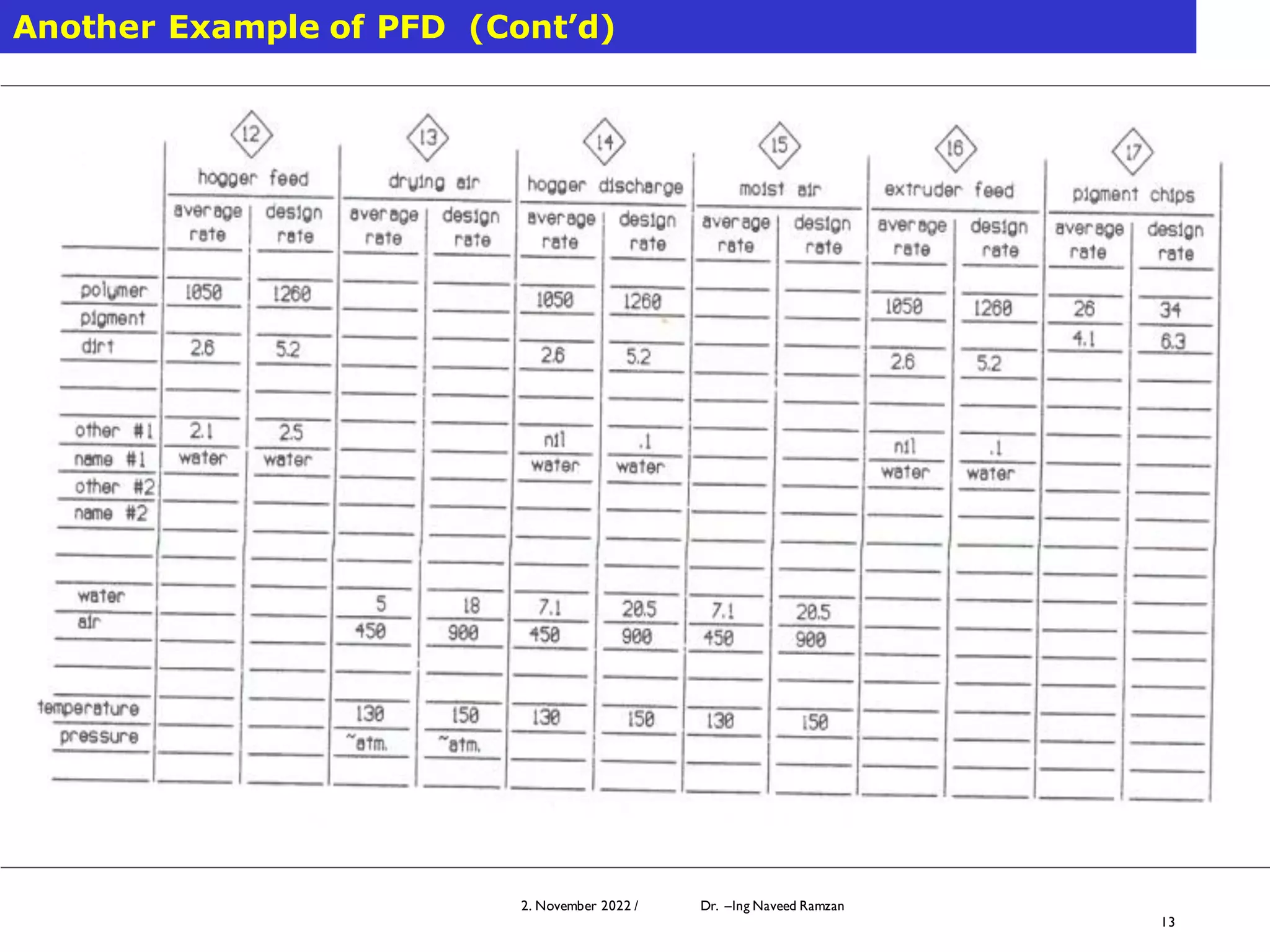

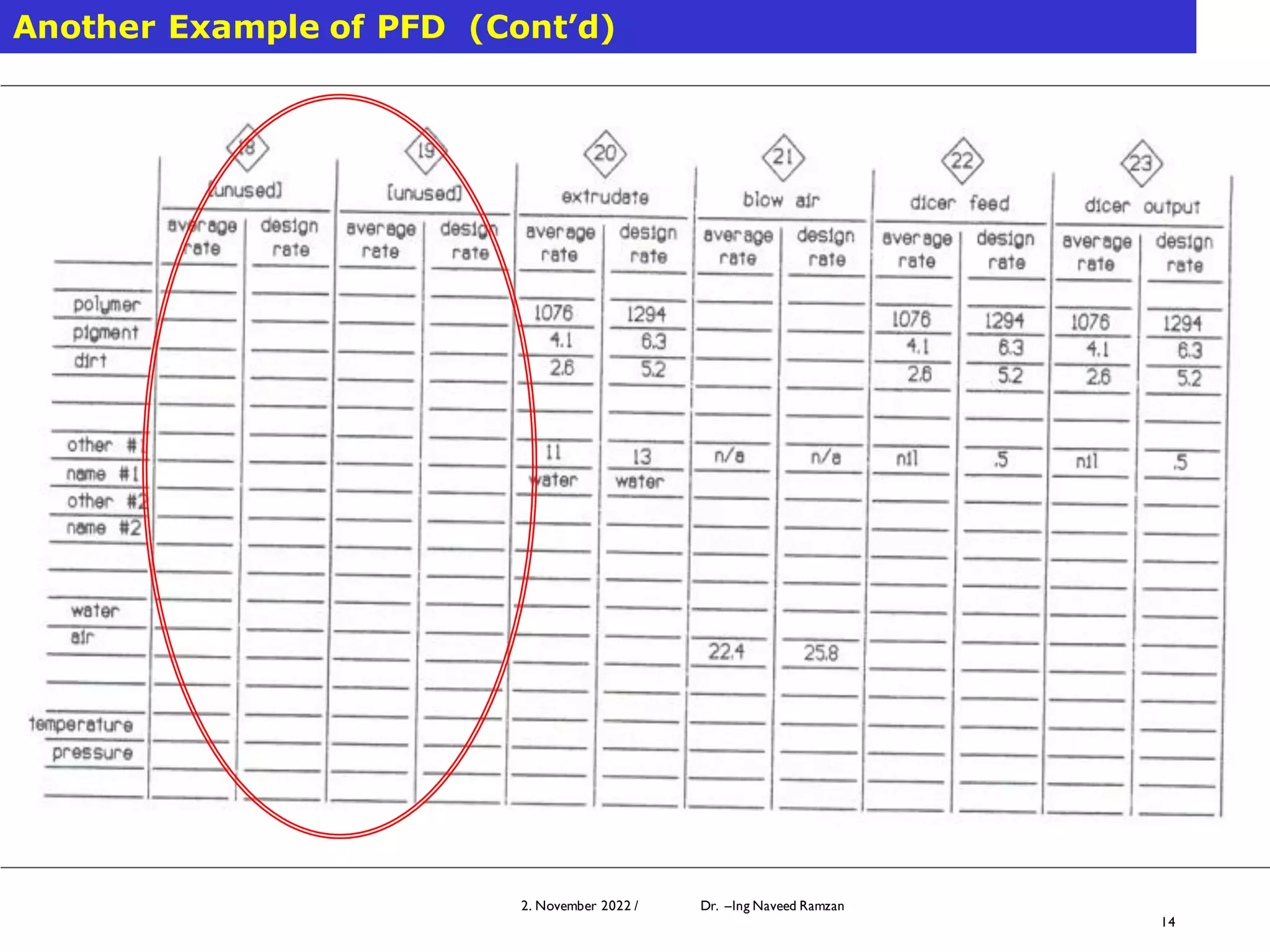

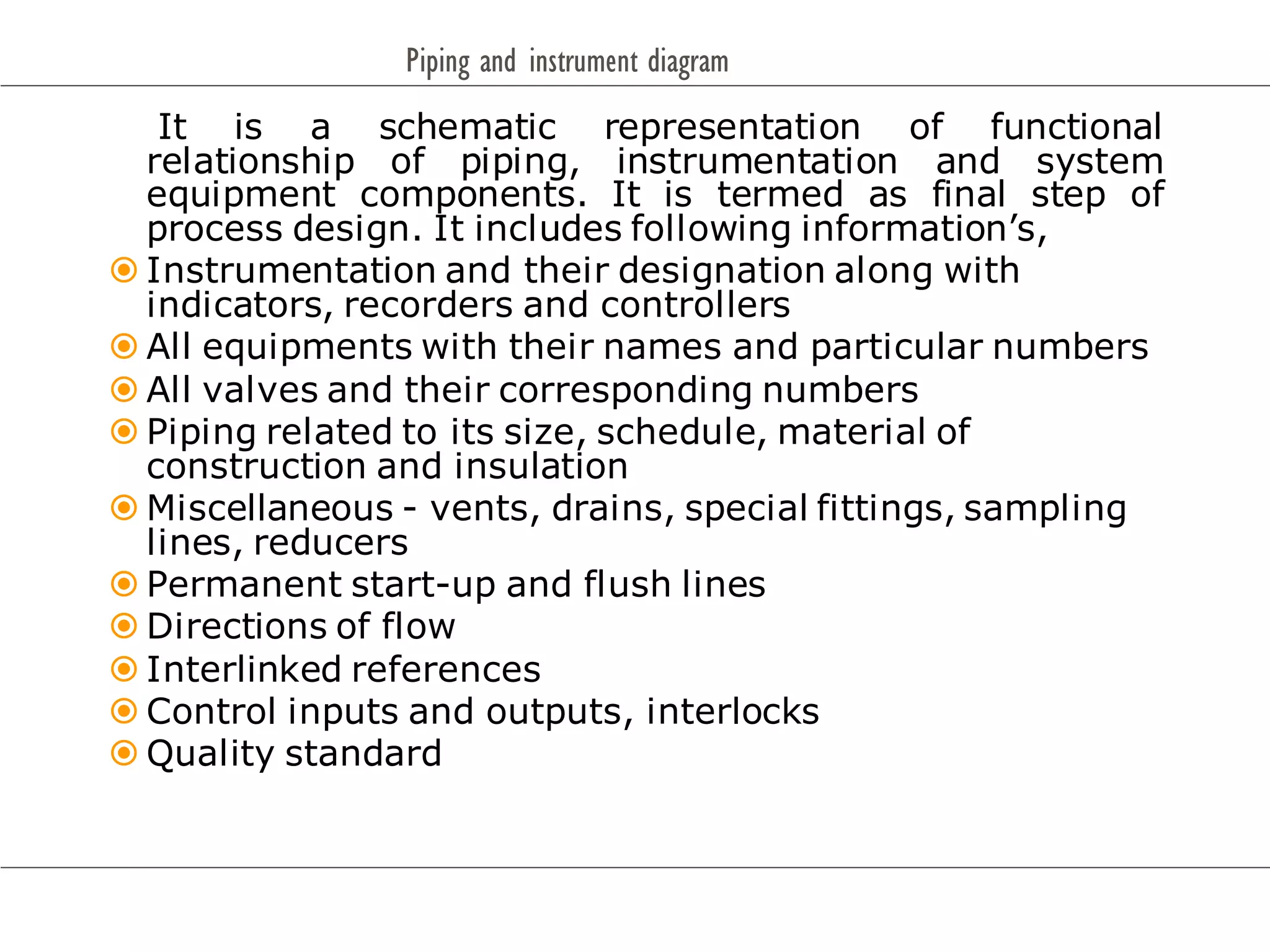

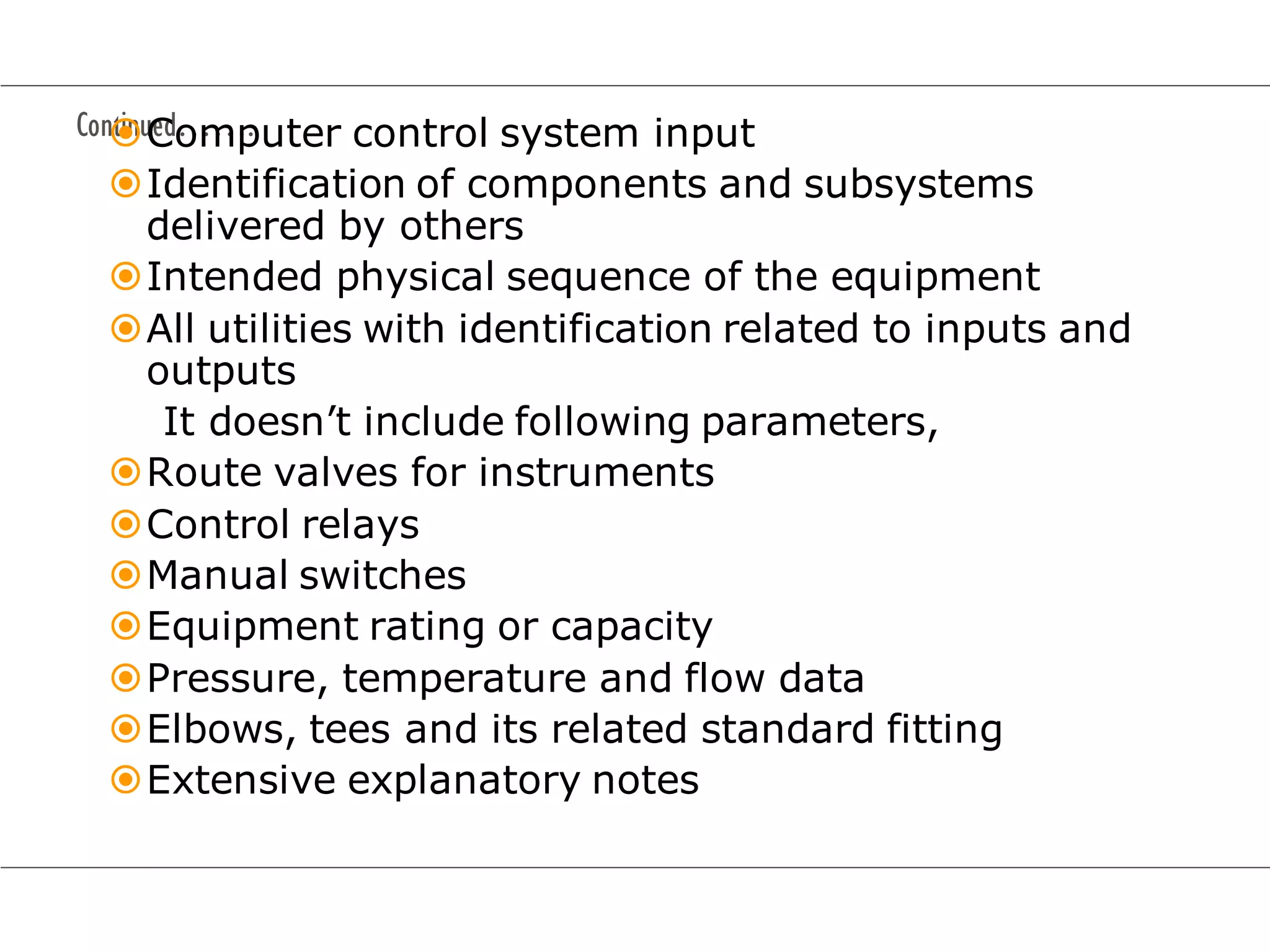

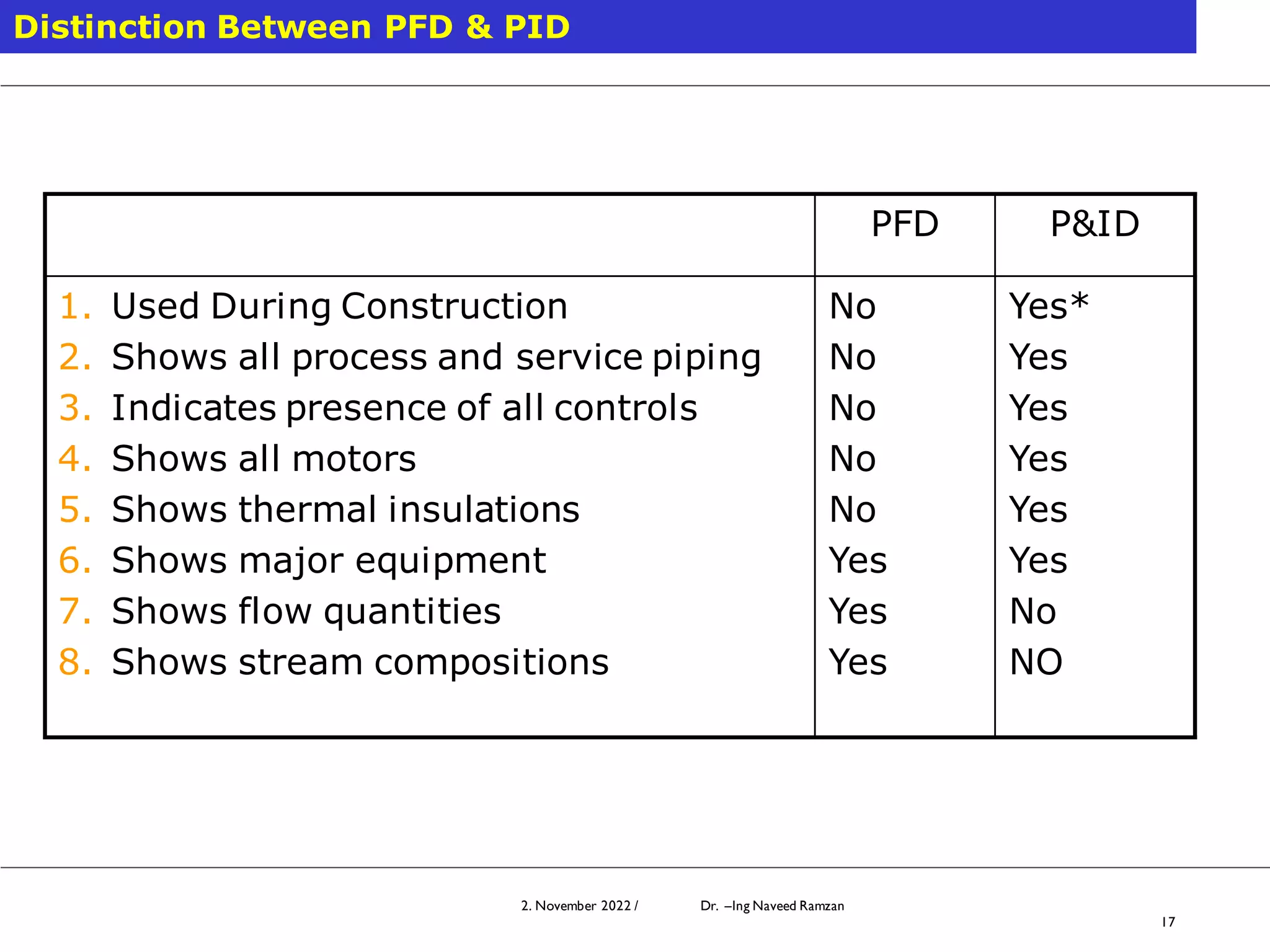

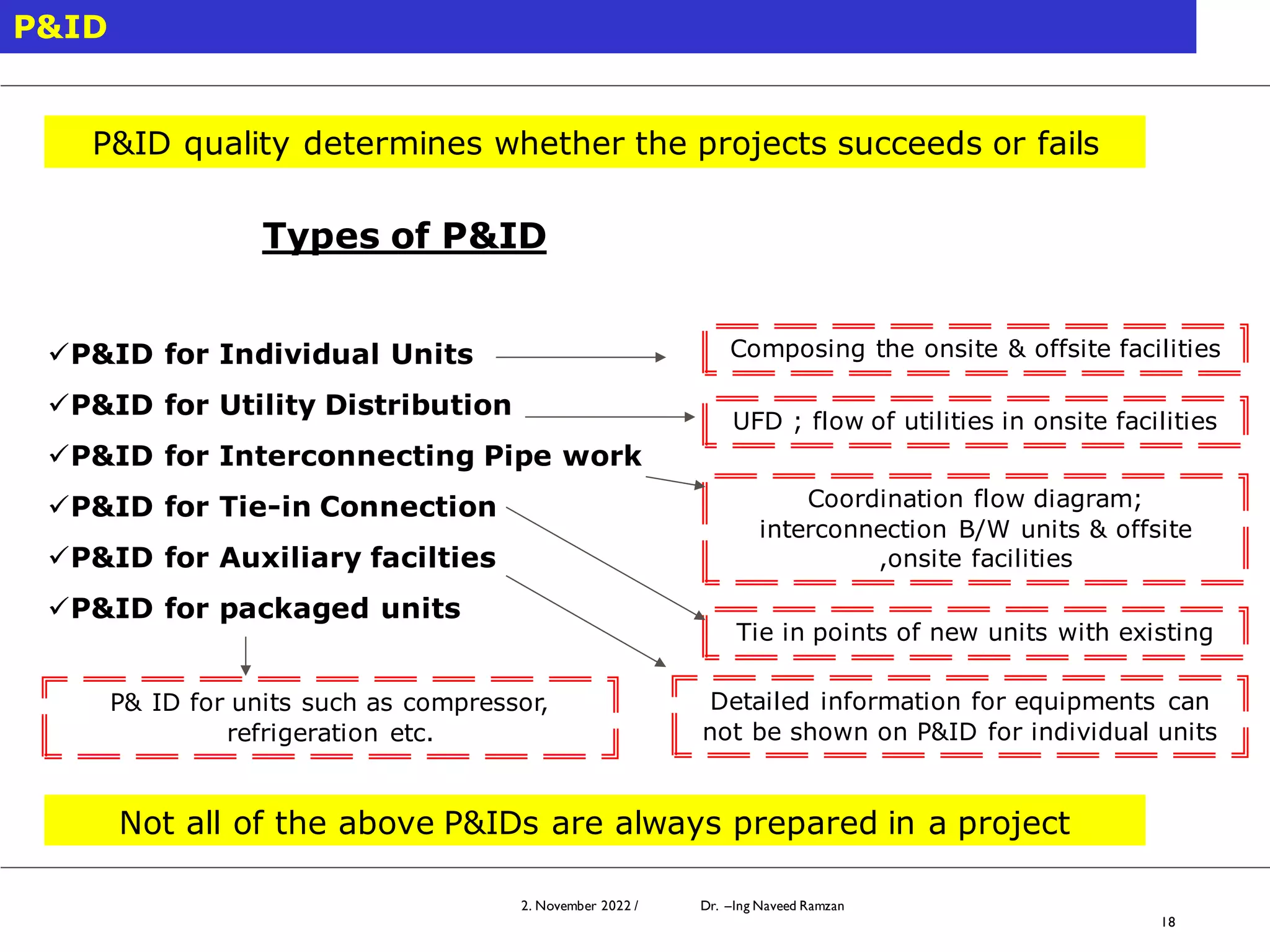

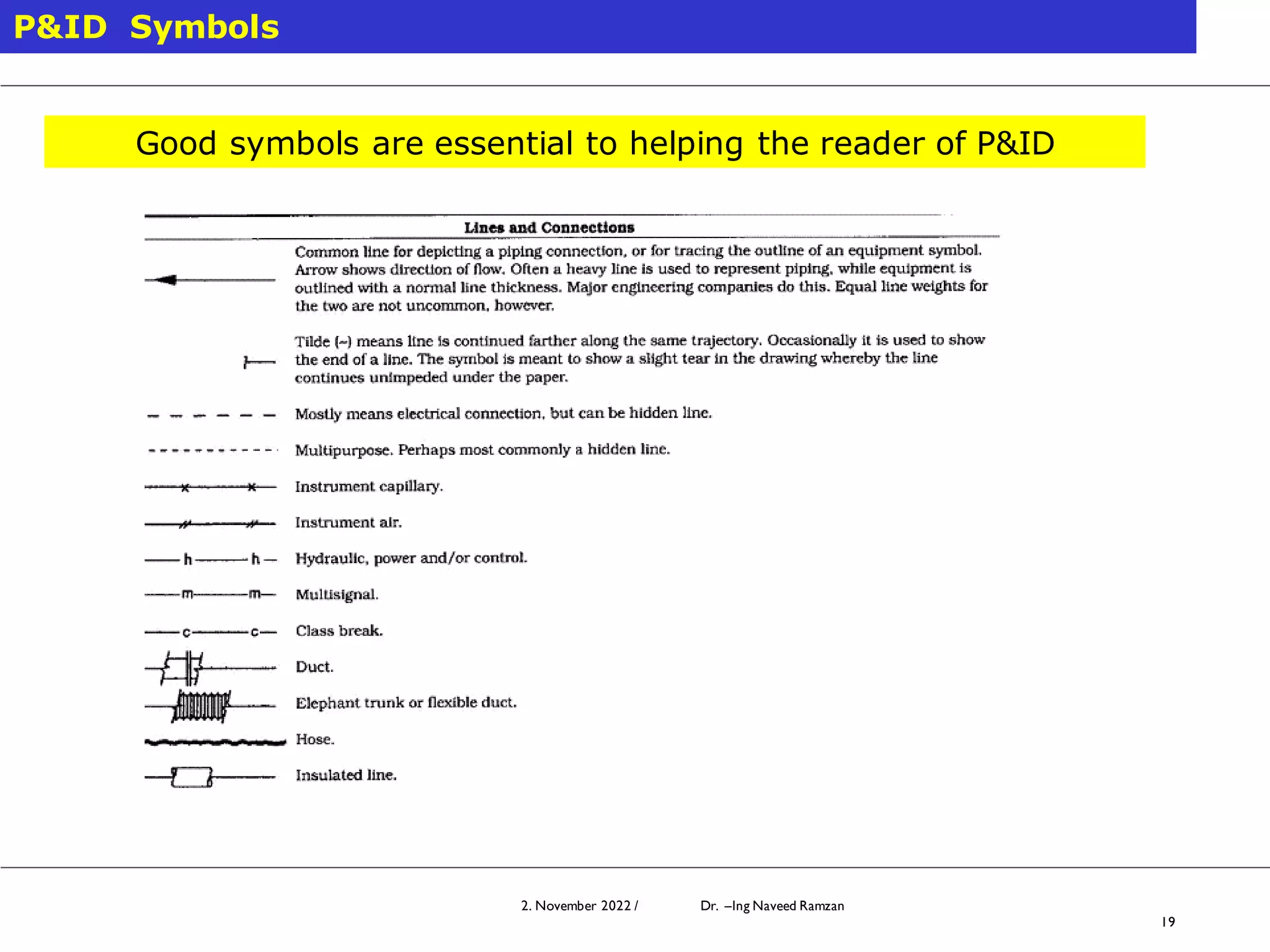

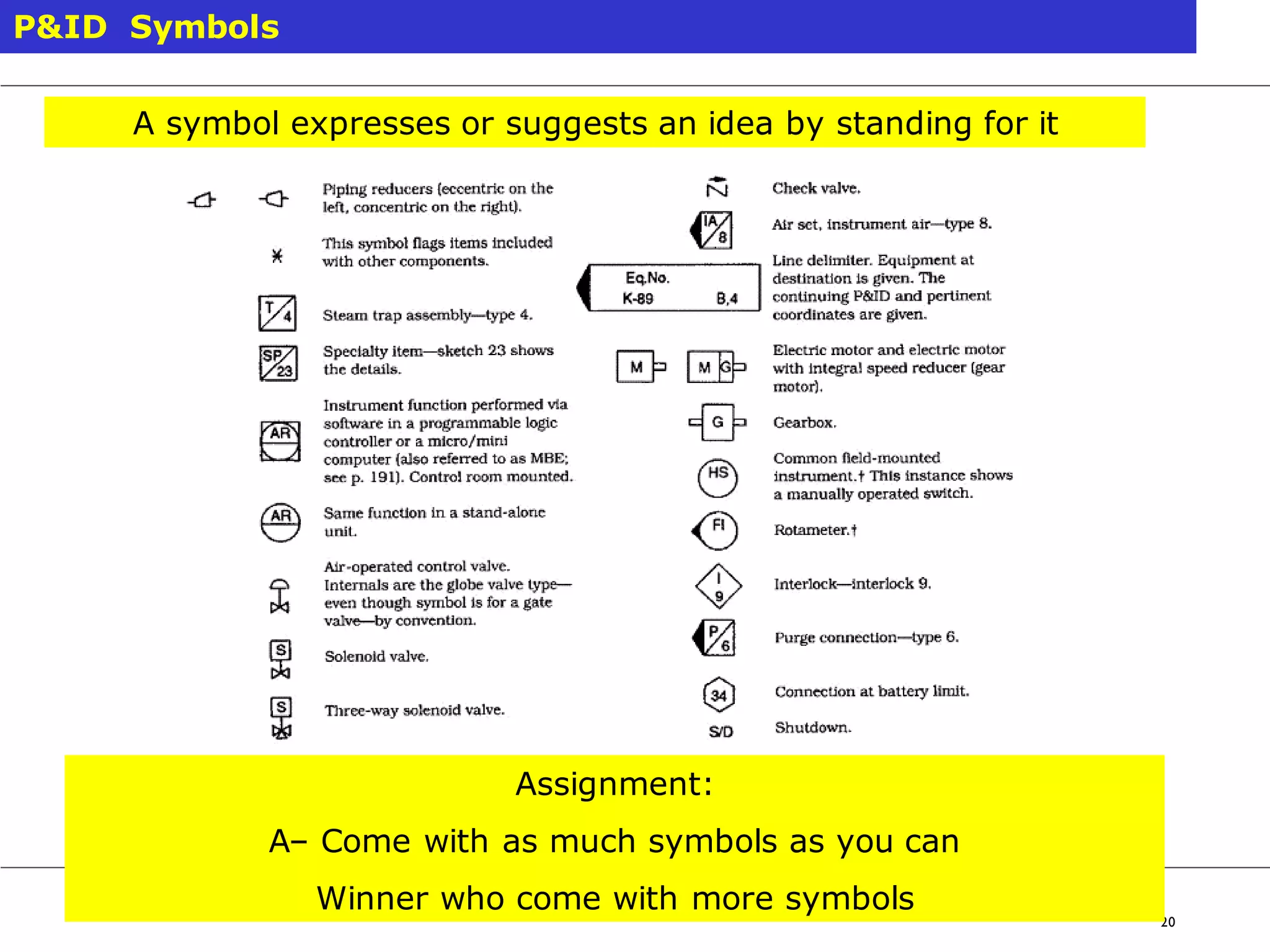

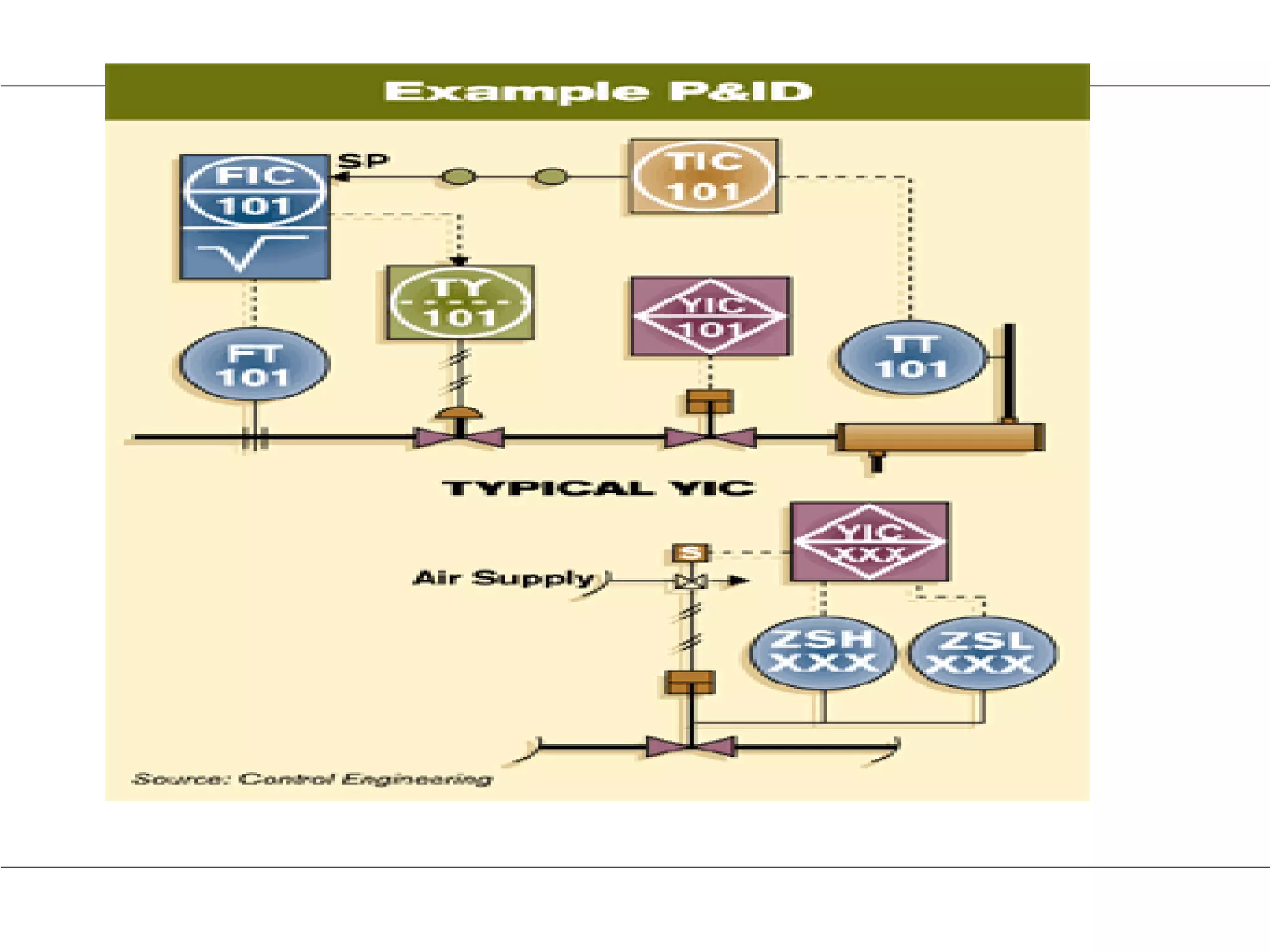

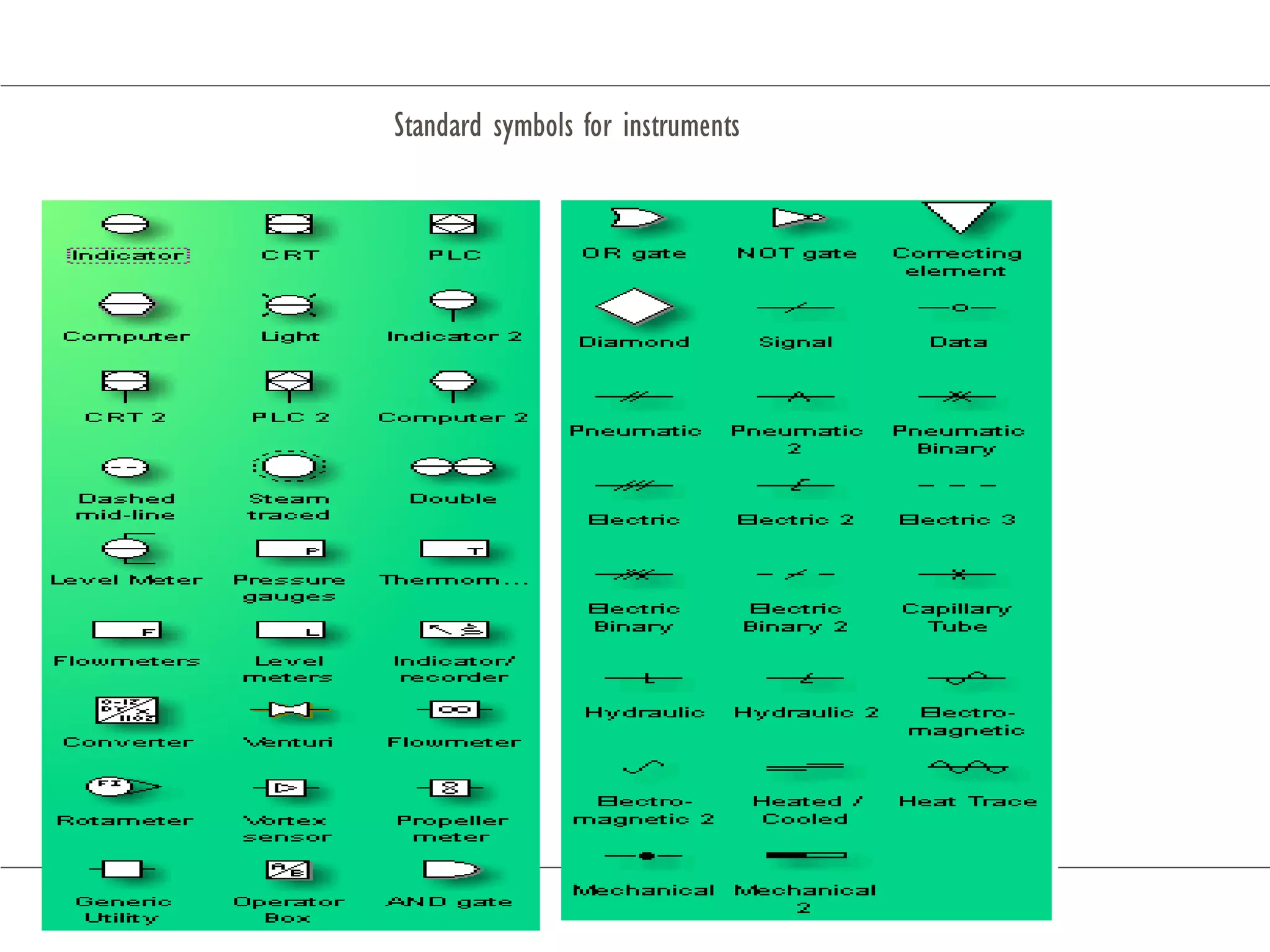

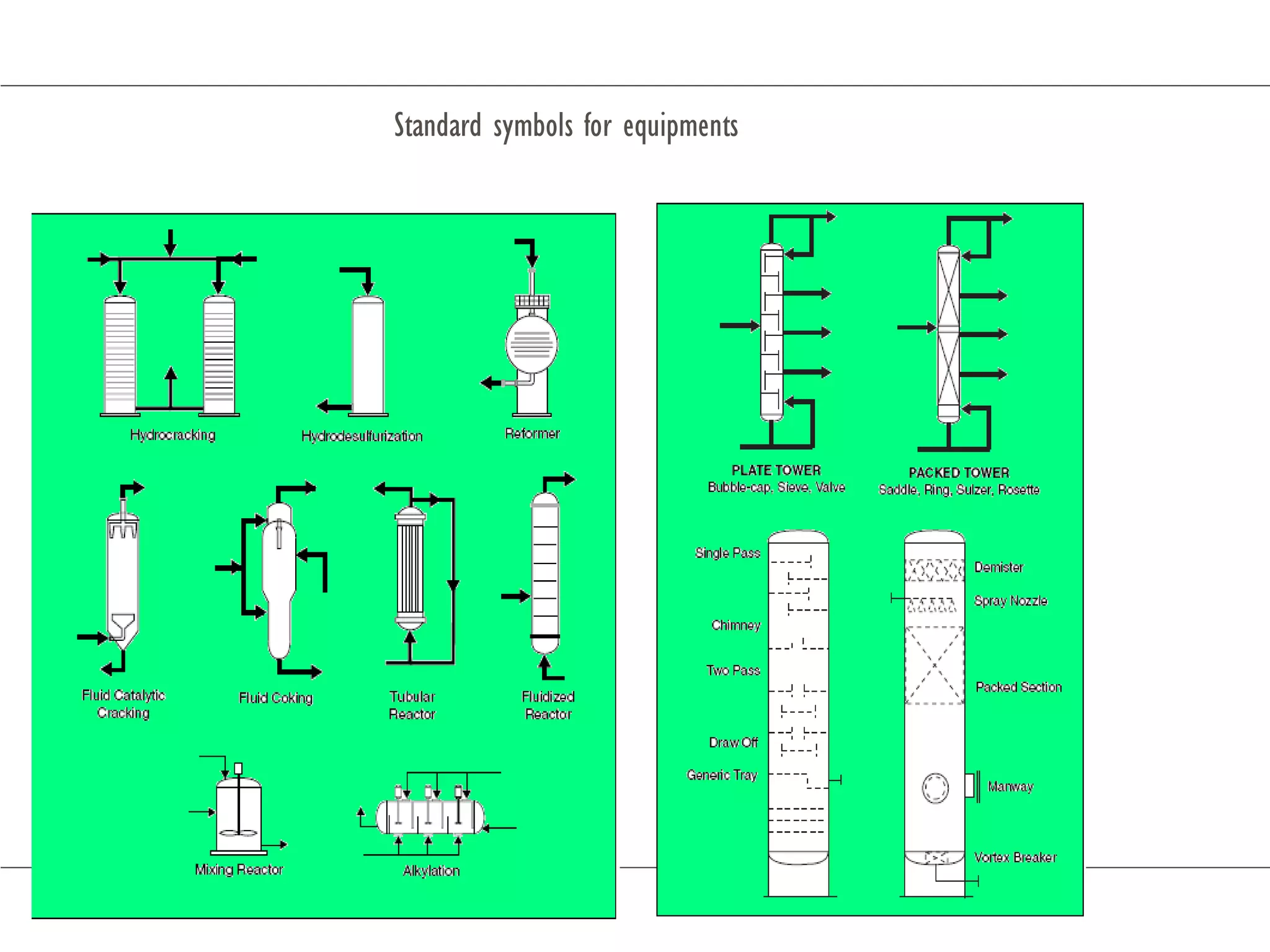

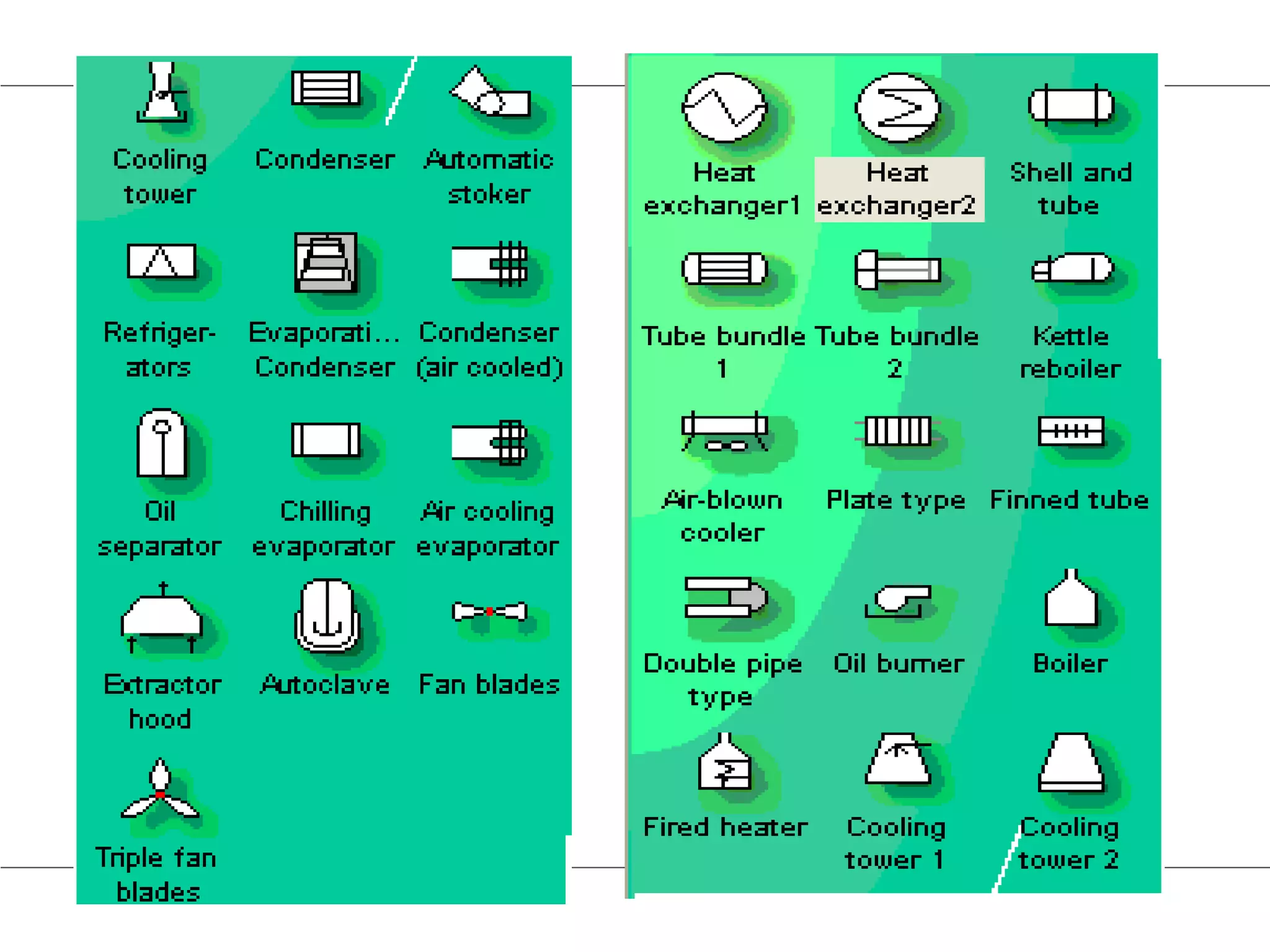

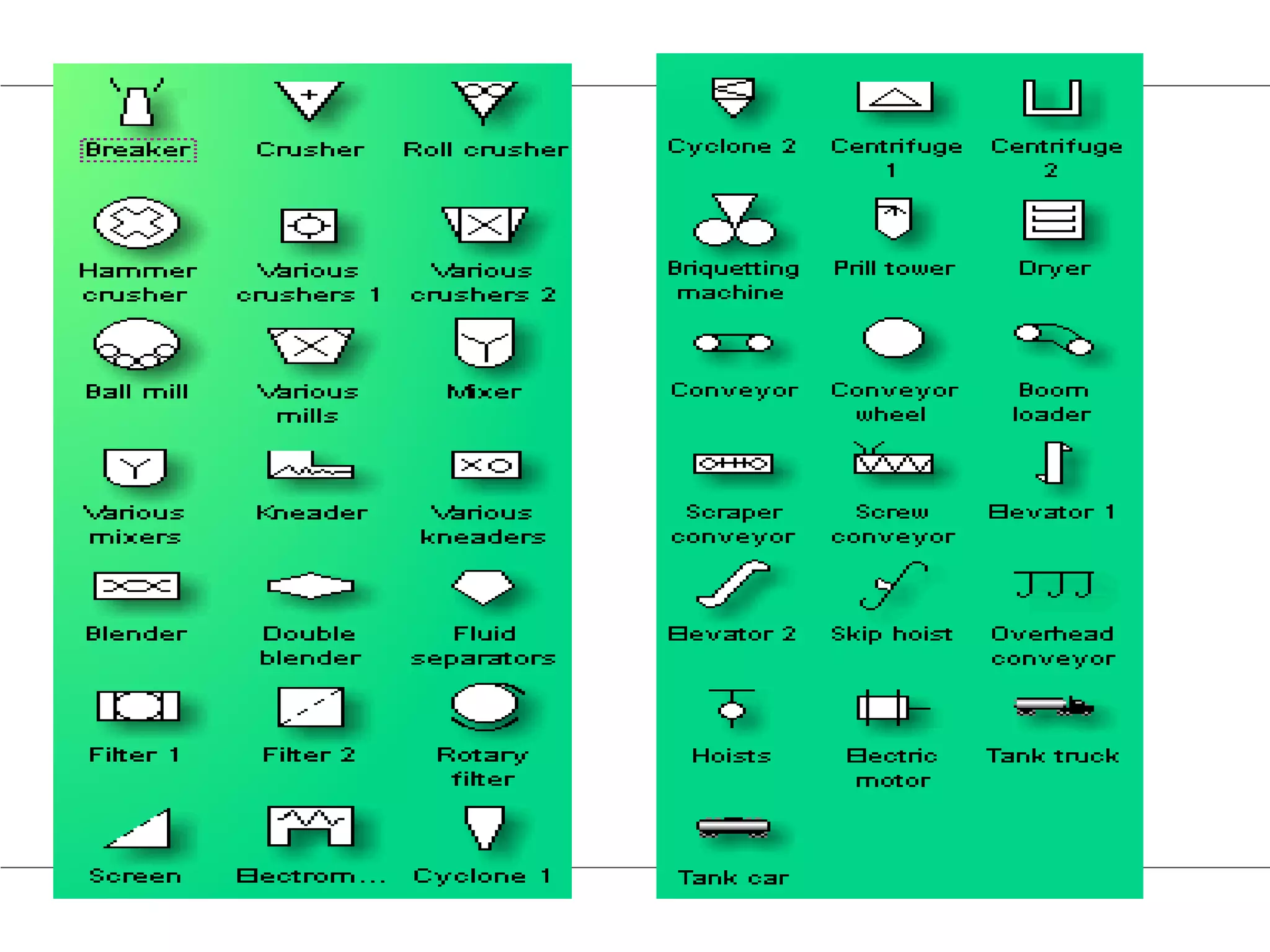

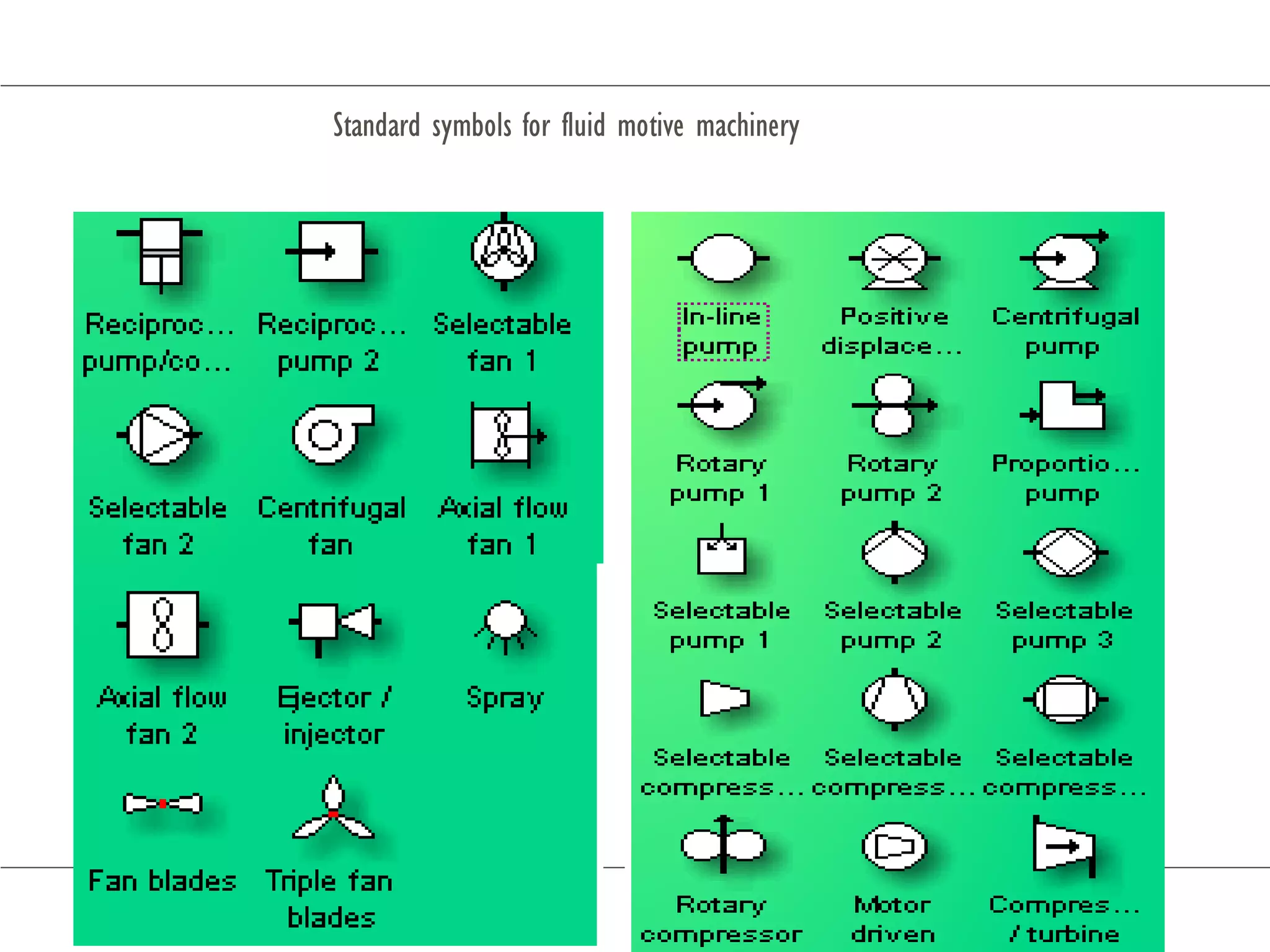

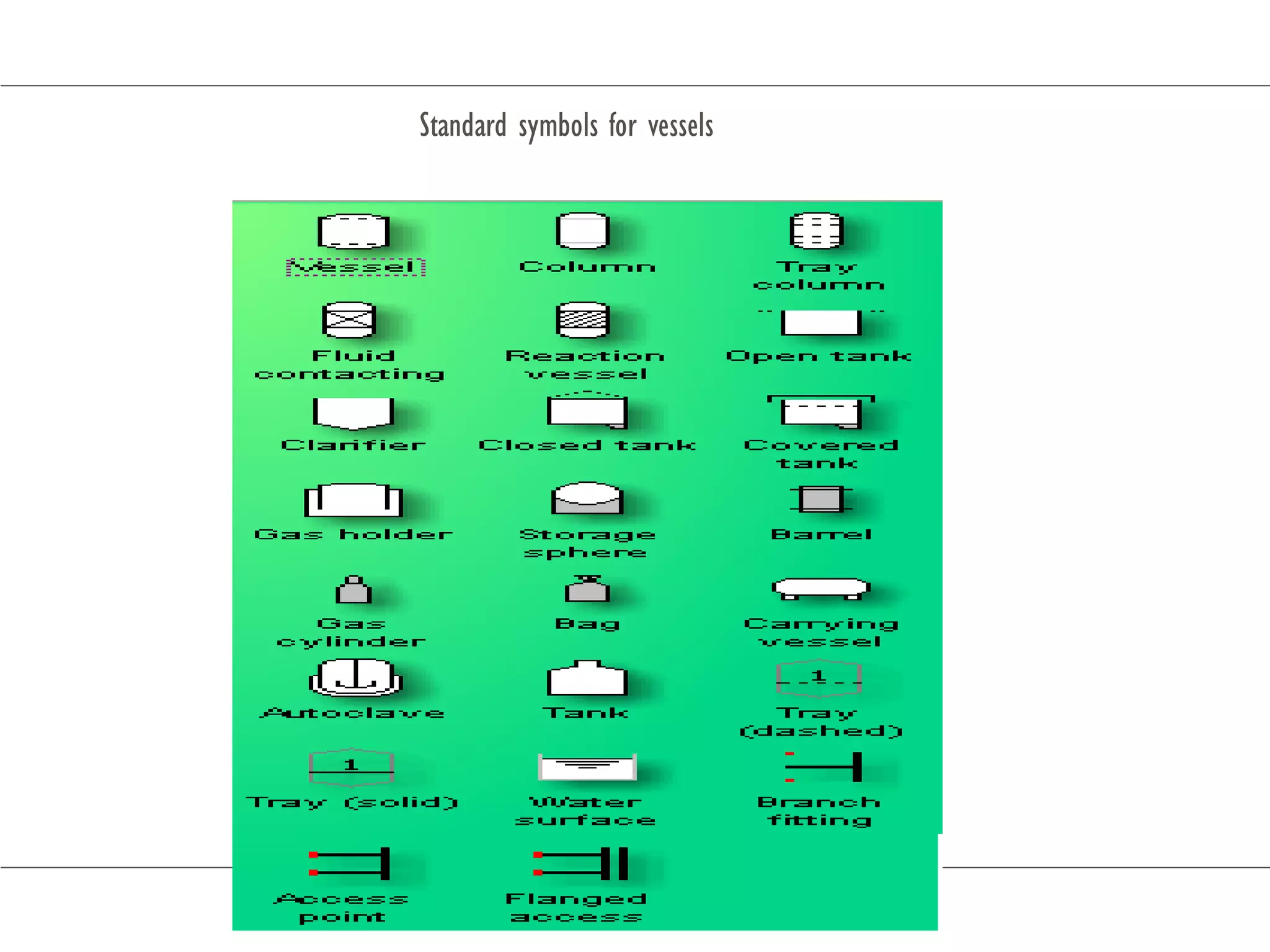

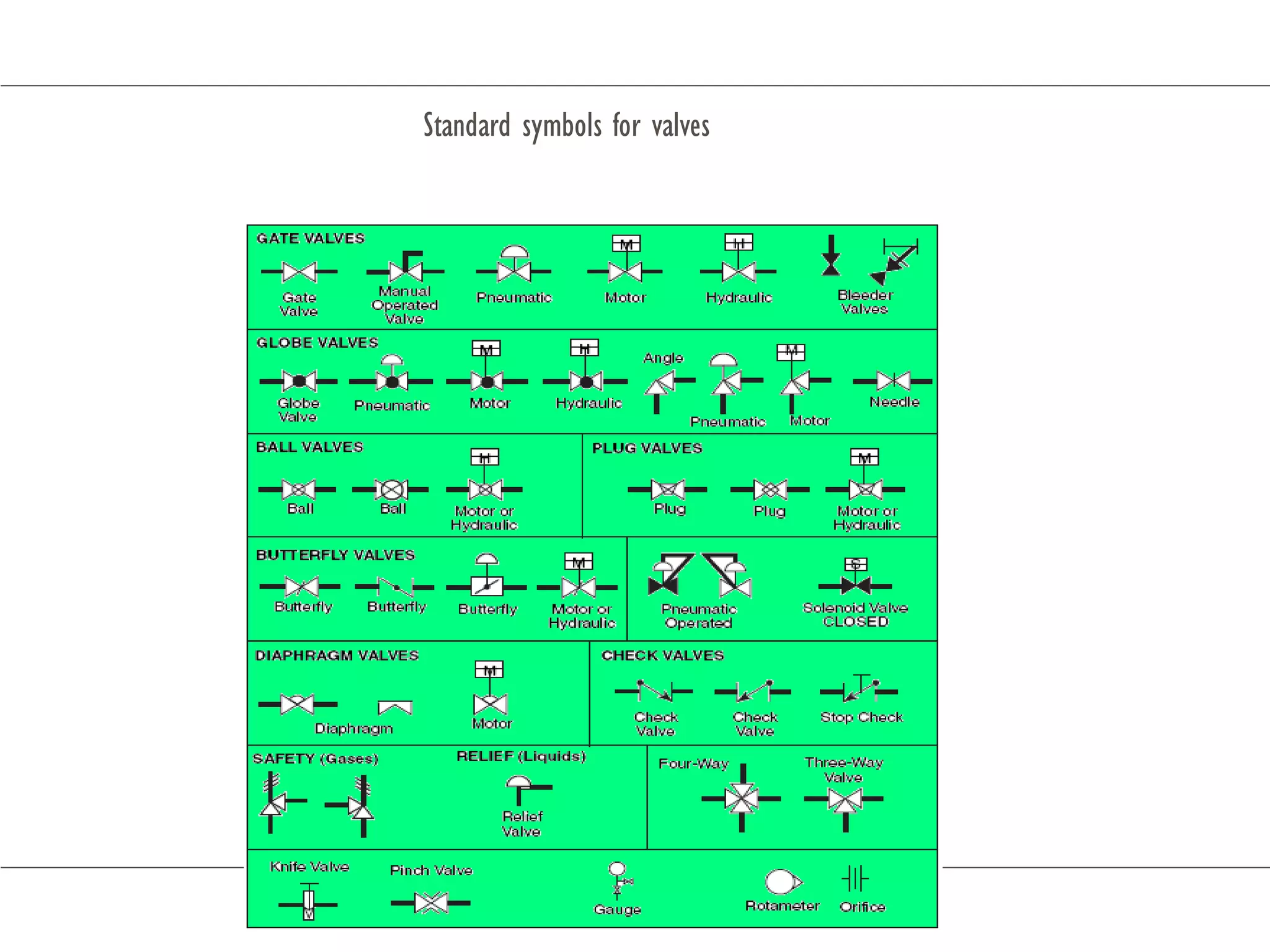

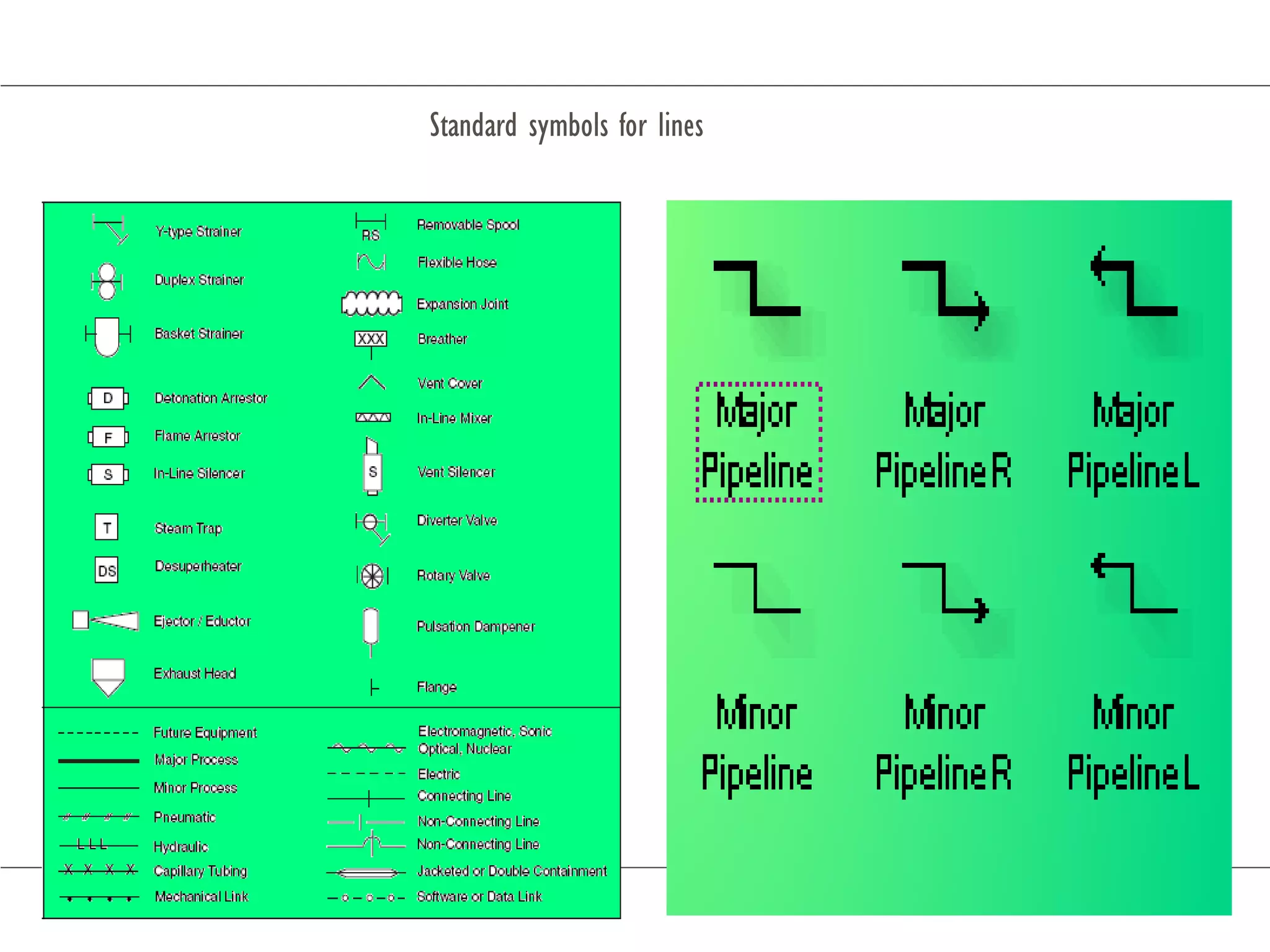

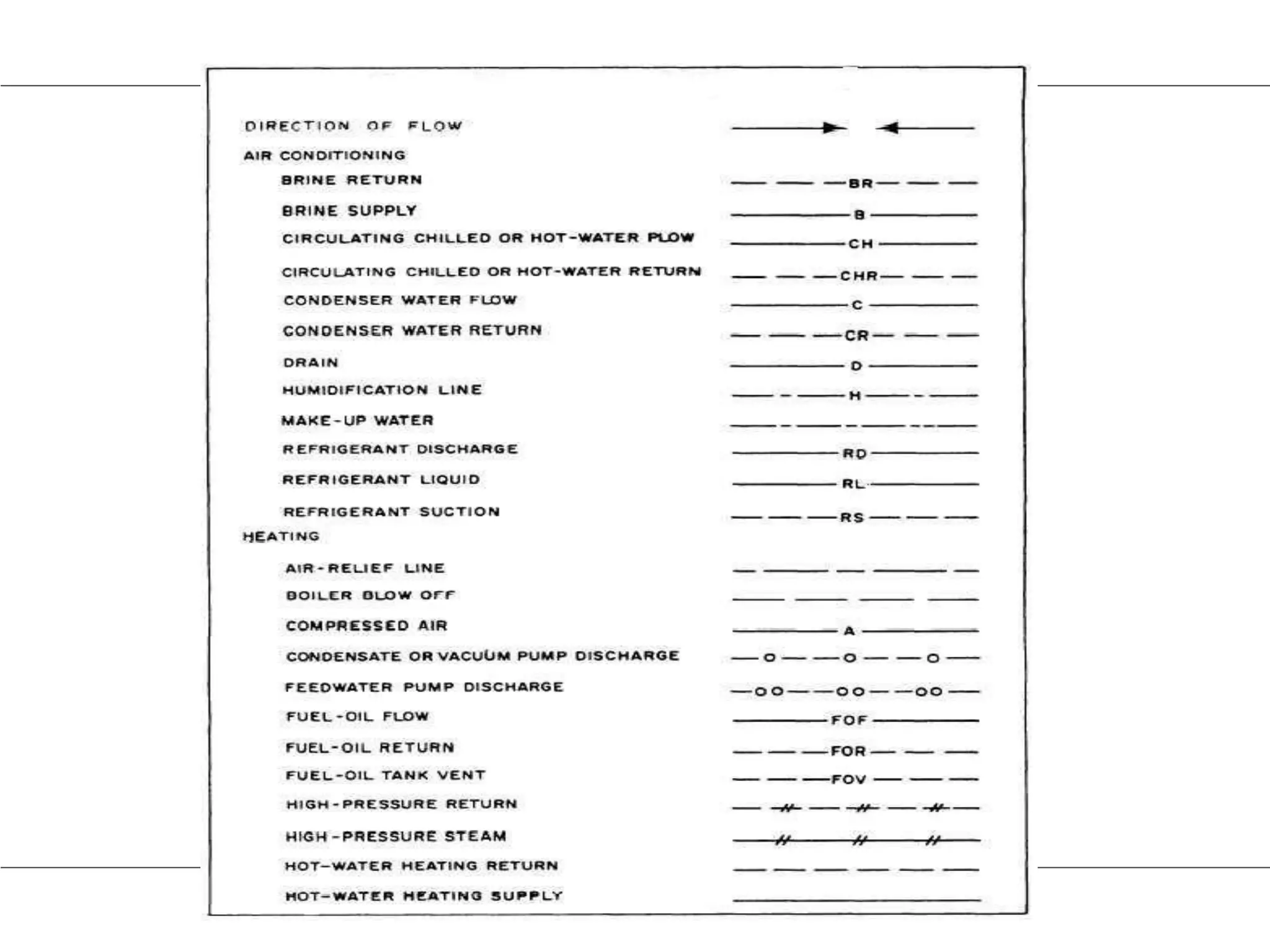

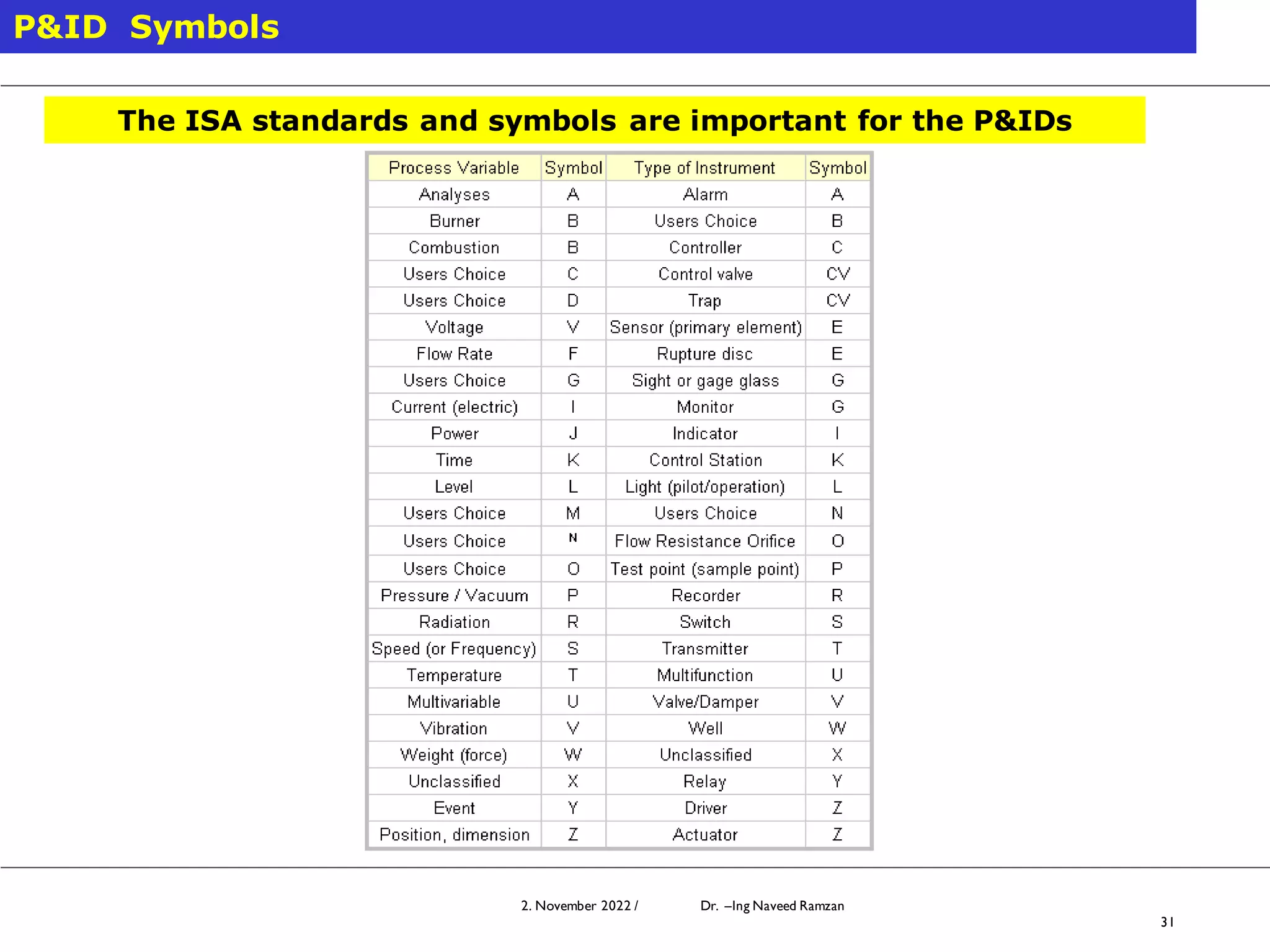

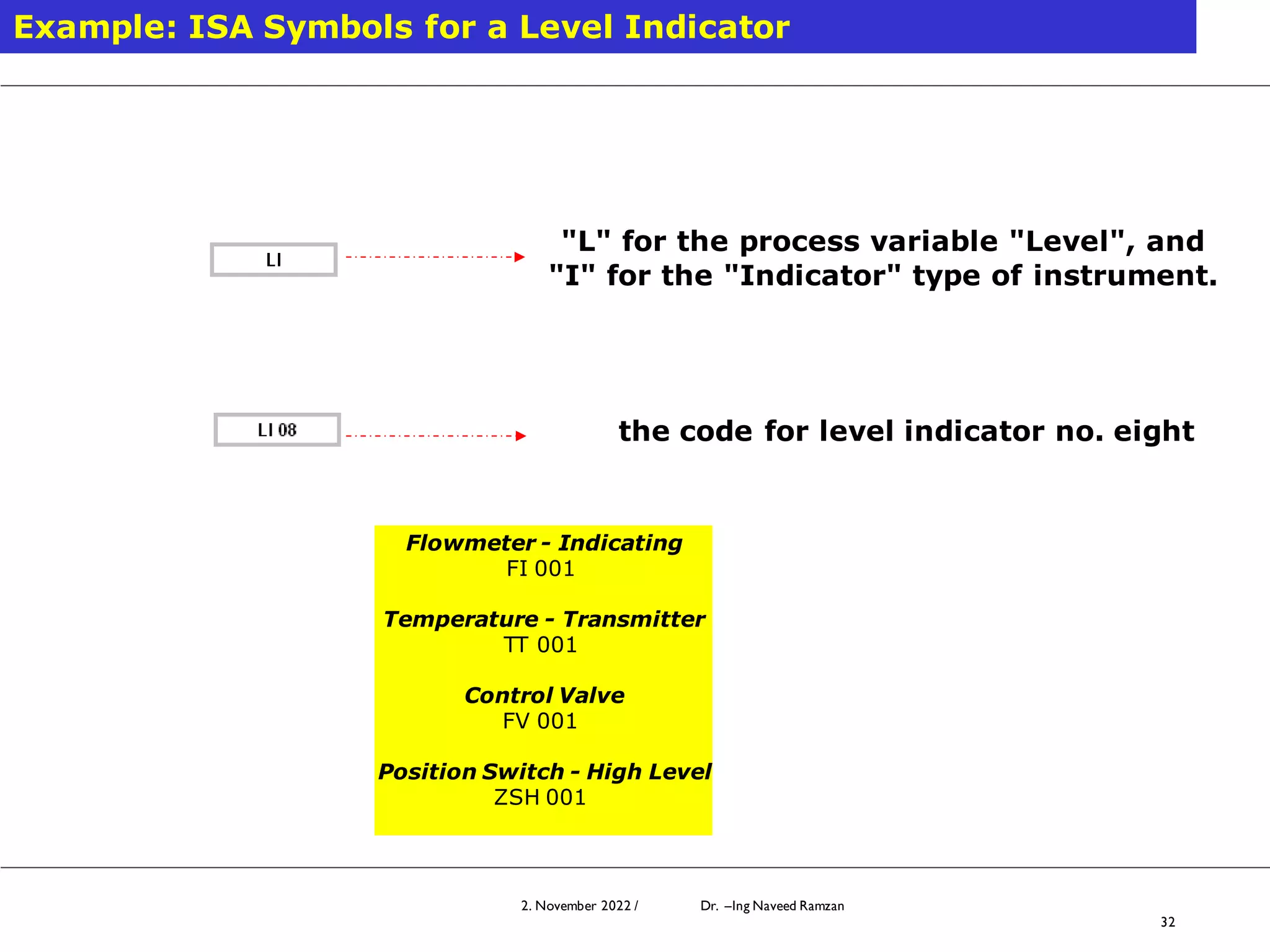

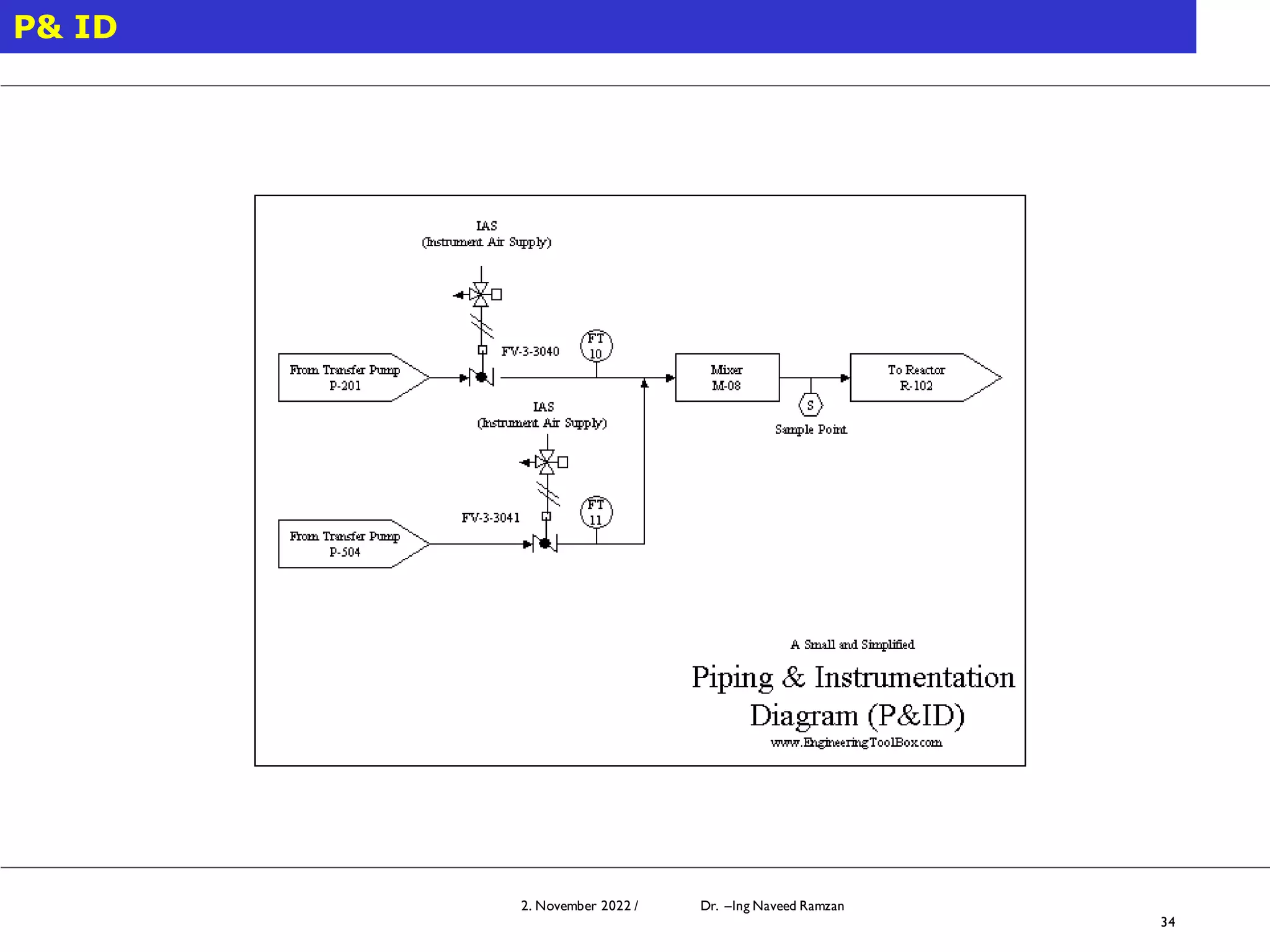

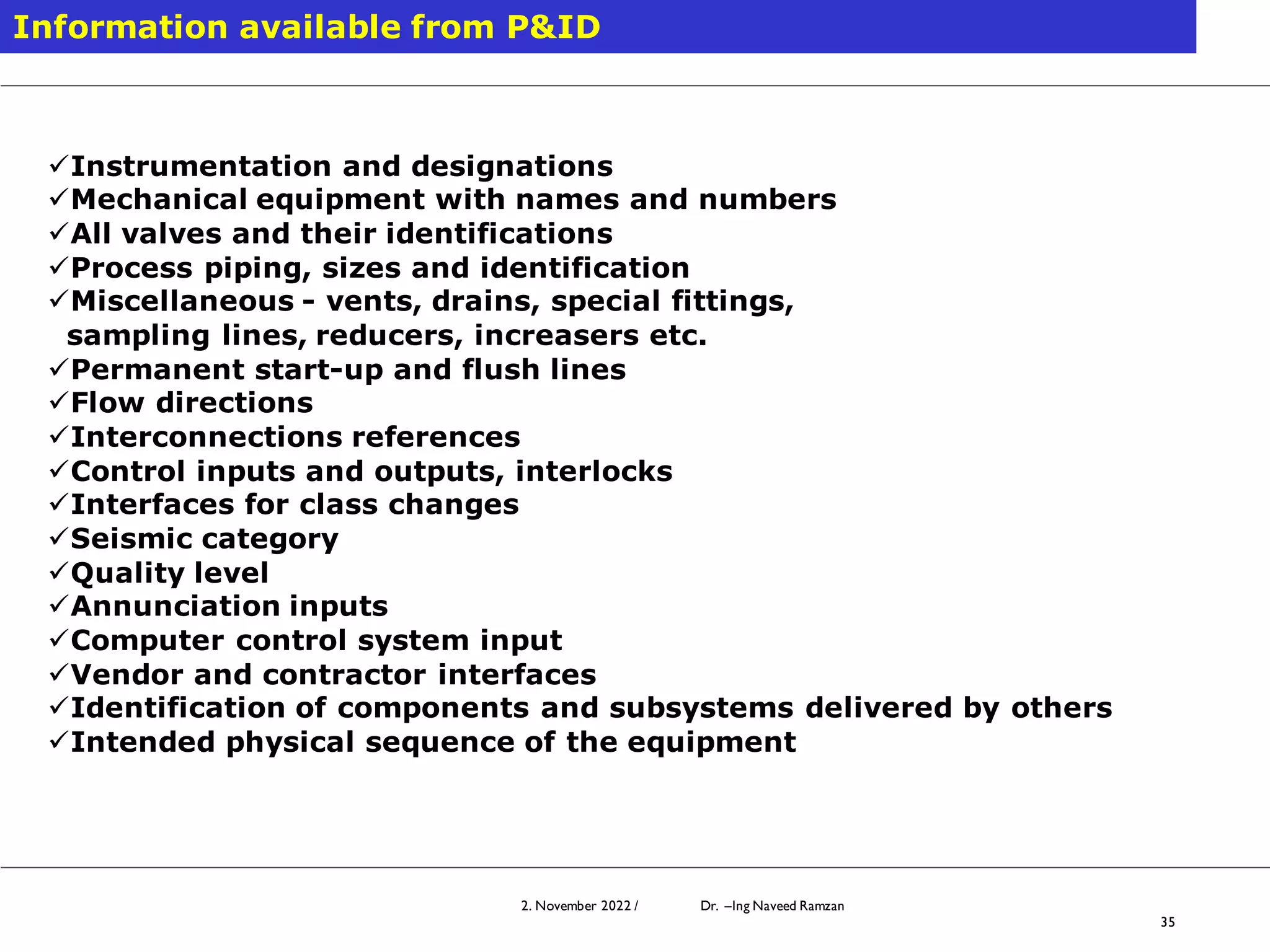

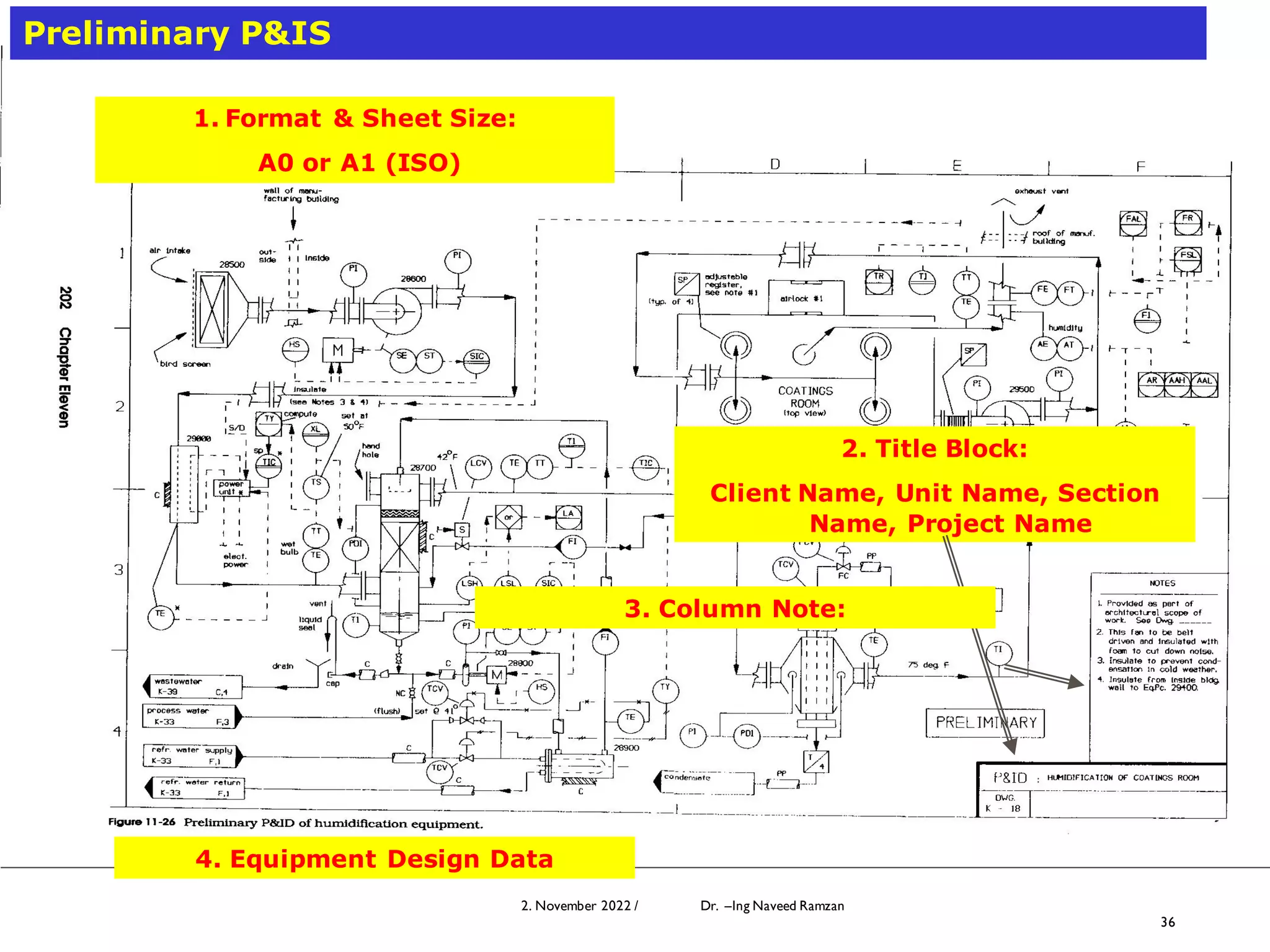

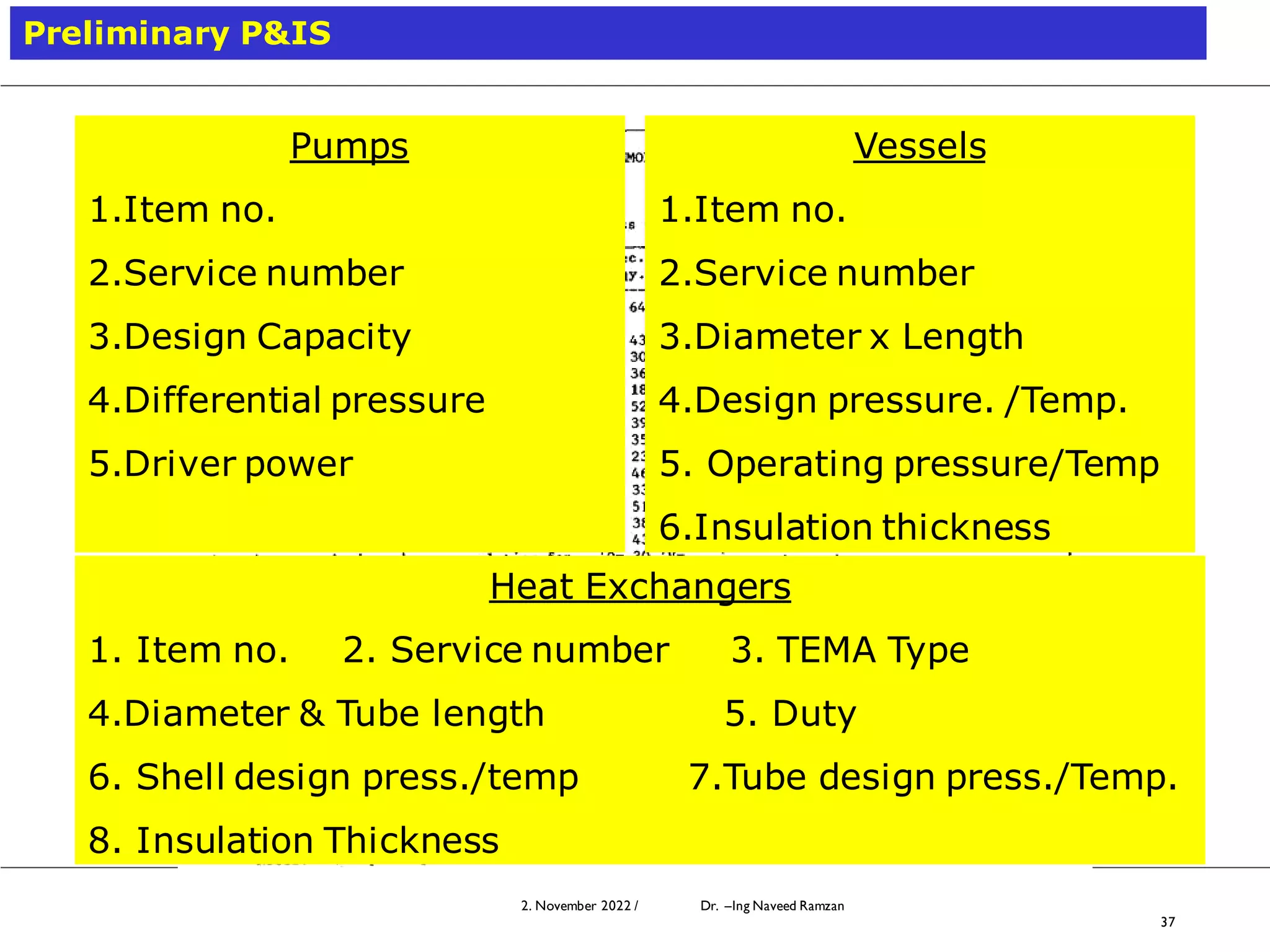

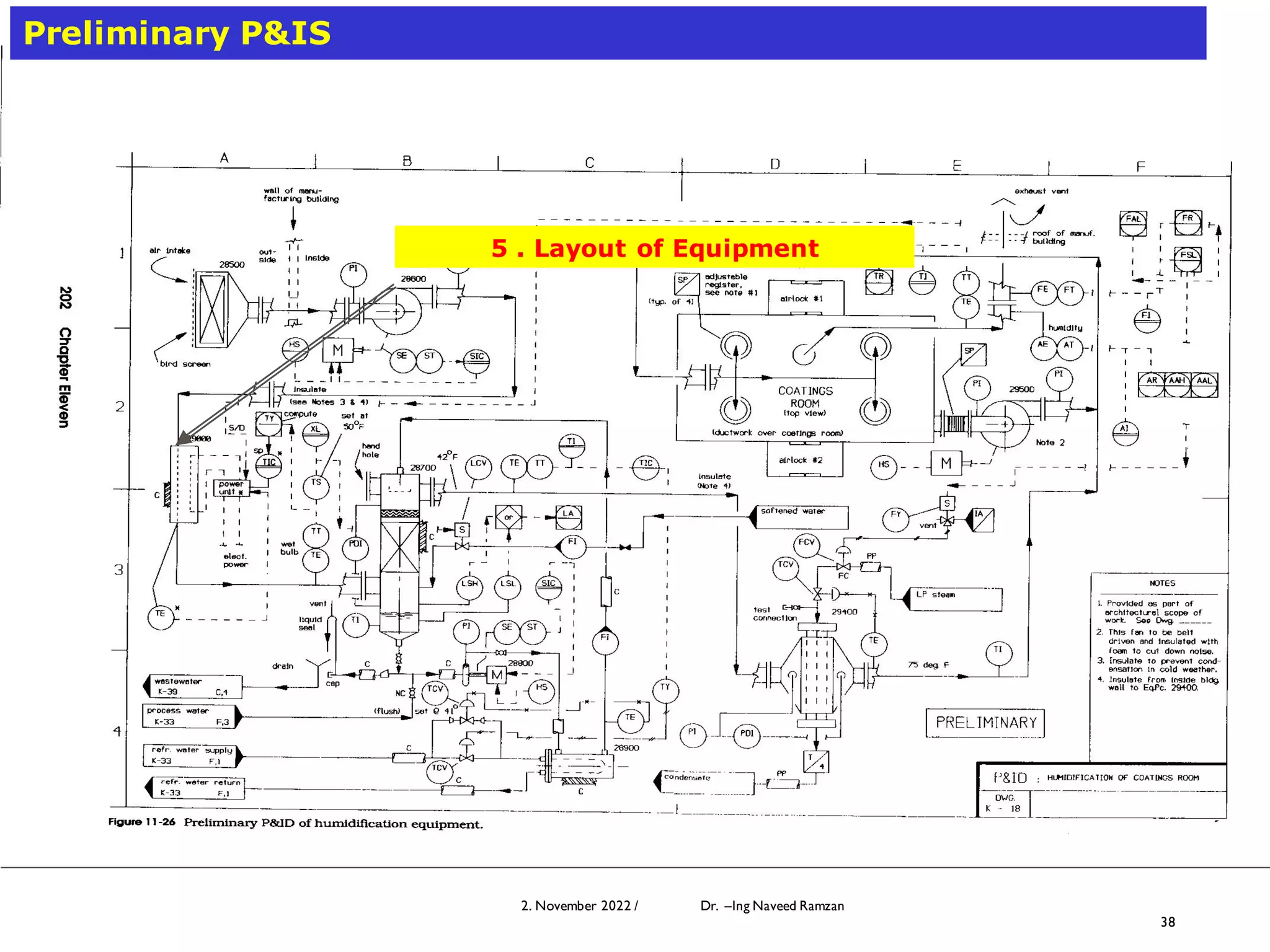

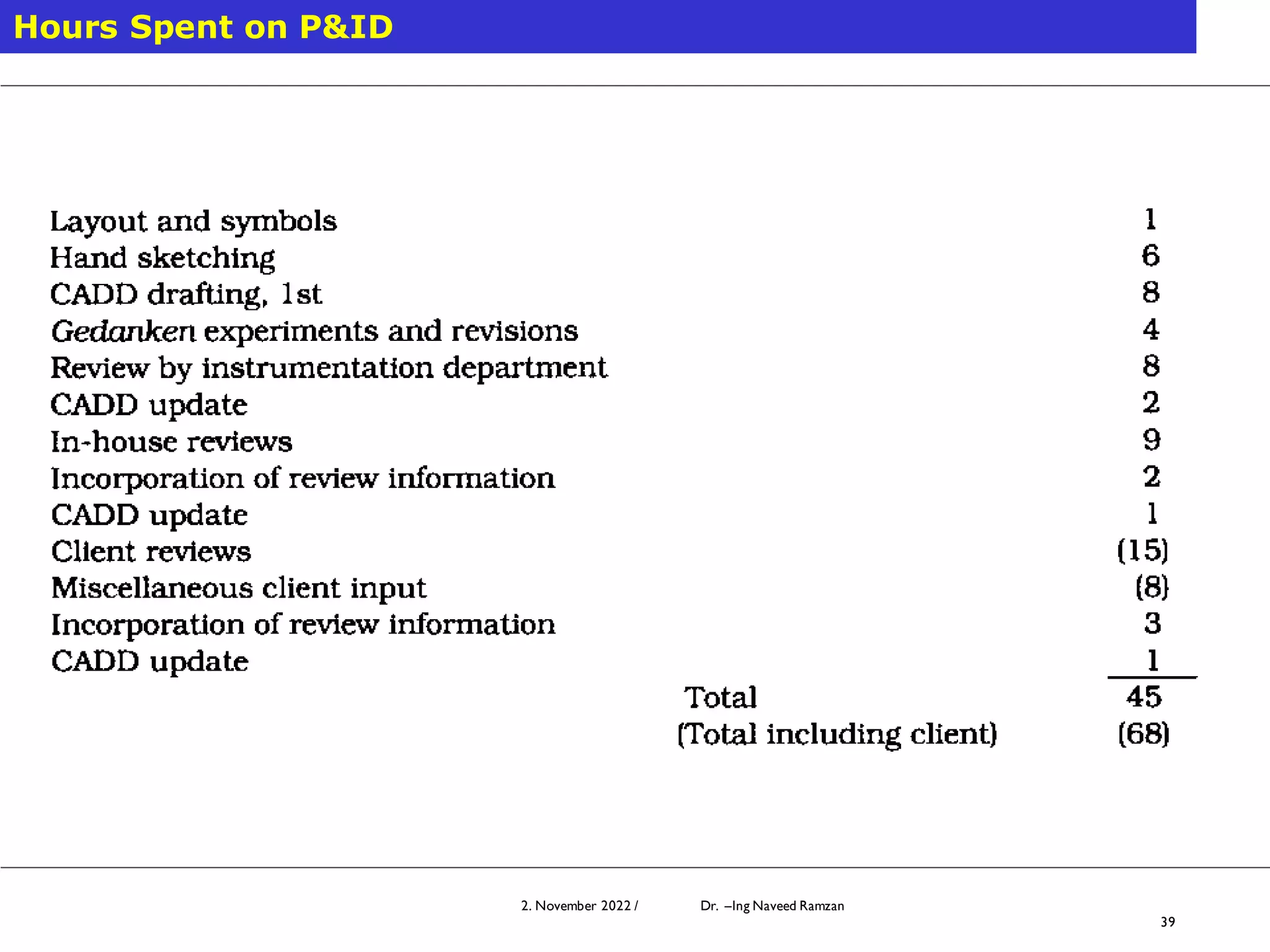

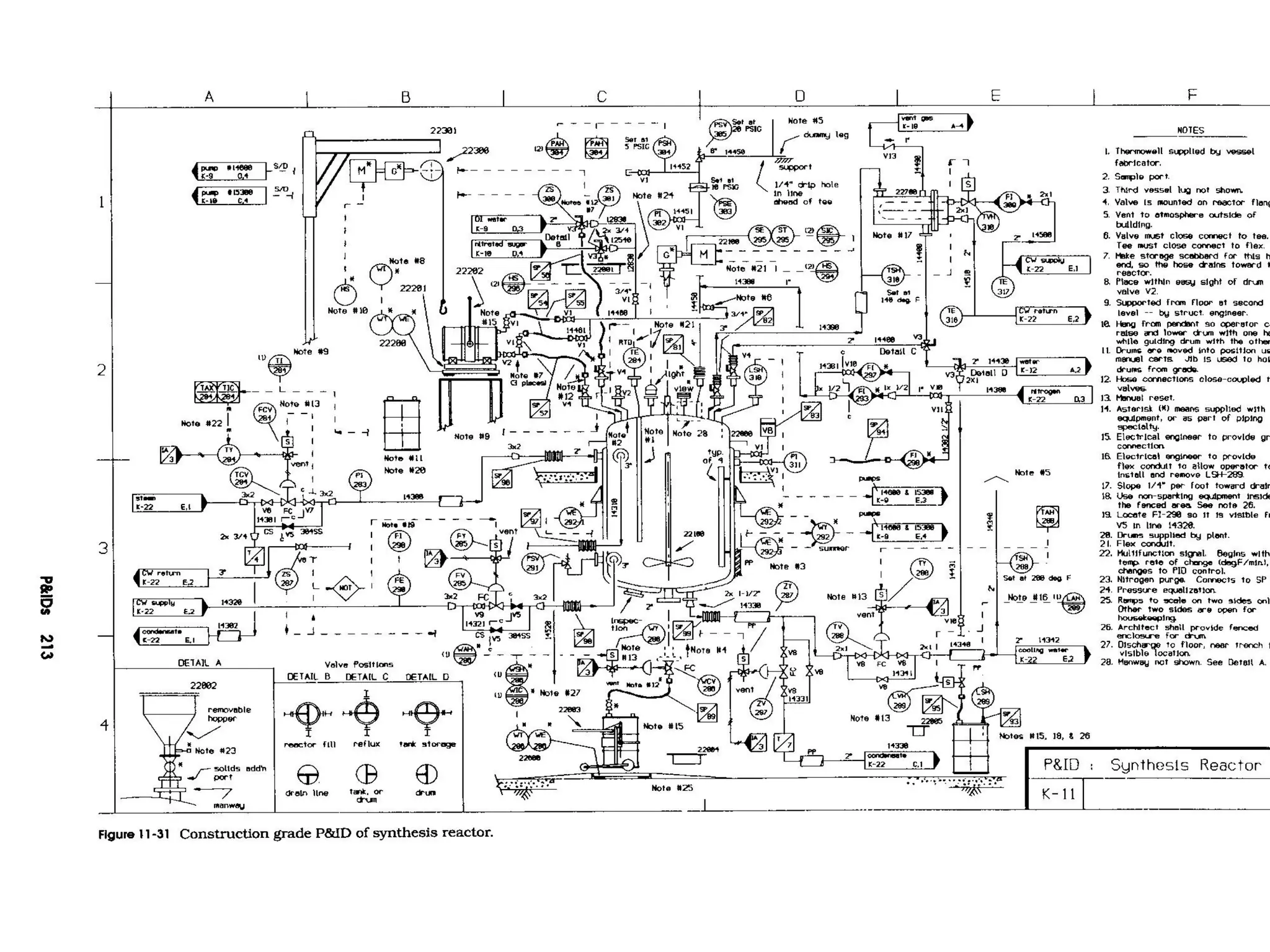

This document discusses piping and instrumentation diagrams (P&IDs). It begins by explaining the sequence of process design and introduces P&IDs. P&IDs are then defined as schematic diagrams that show the functional relationships between piping, instrumentation, and process equipment. The document contrasts P&IDs with other process design diagrams like block flow diagrams and process flow diagrams. It provides examples of common symbols used in P&IDs and discusses the information that can be found in P&IDs, such as equipment, valves, piping details, and instrumentation. Finally, it notes the significant time spent developing preliminary P&IDs.