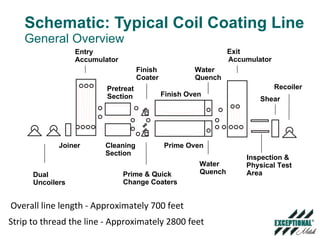

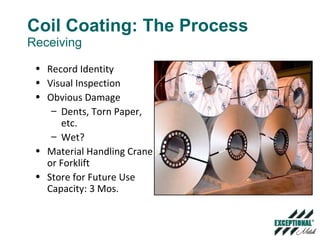

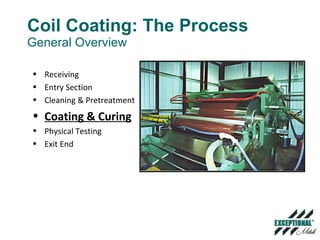

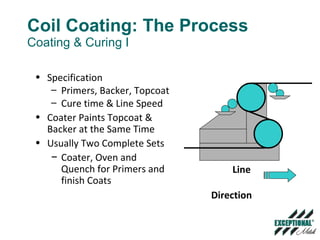

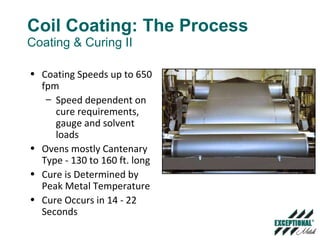

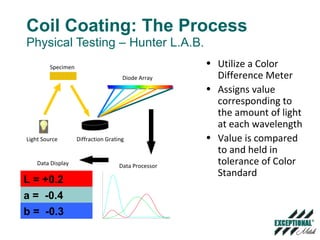

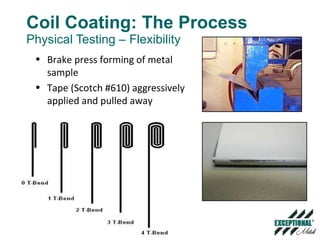

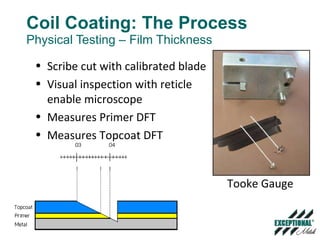

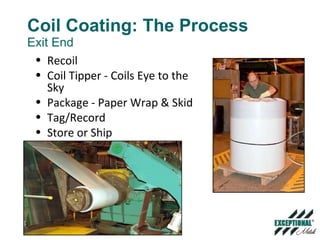

The document describes the coil coating process, which involves cleaning and pretreating steel coils before applying primer and topcoat paint in a continuous line. Key steps include receiving raw coils, pretreating with chemicals to prepare the surface, applying primer and topcoat via coater ovens, and testing finished coils through procedures like measuring gloss, flexibility, and solvent resistance.