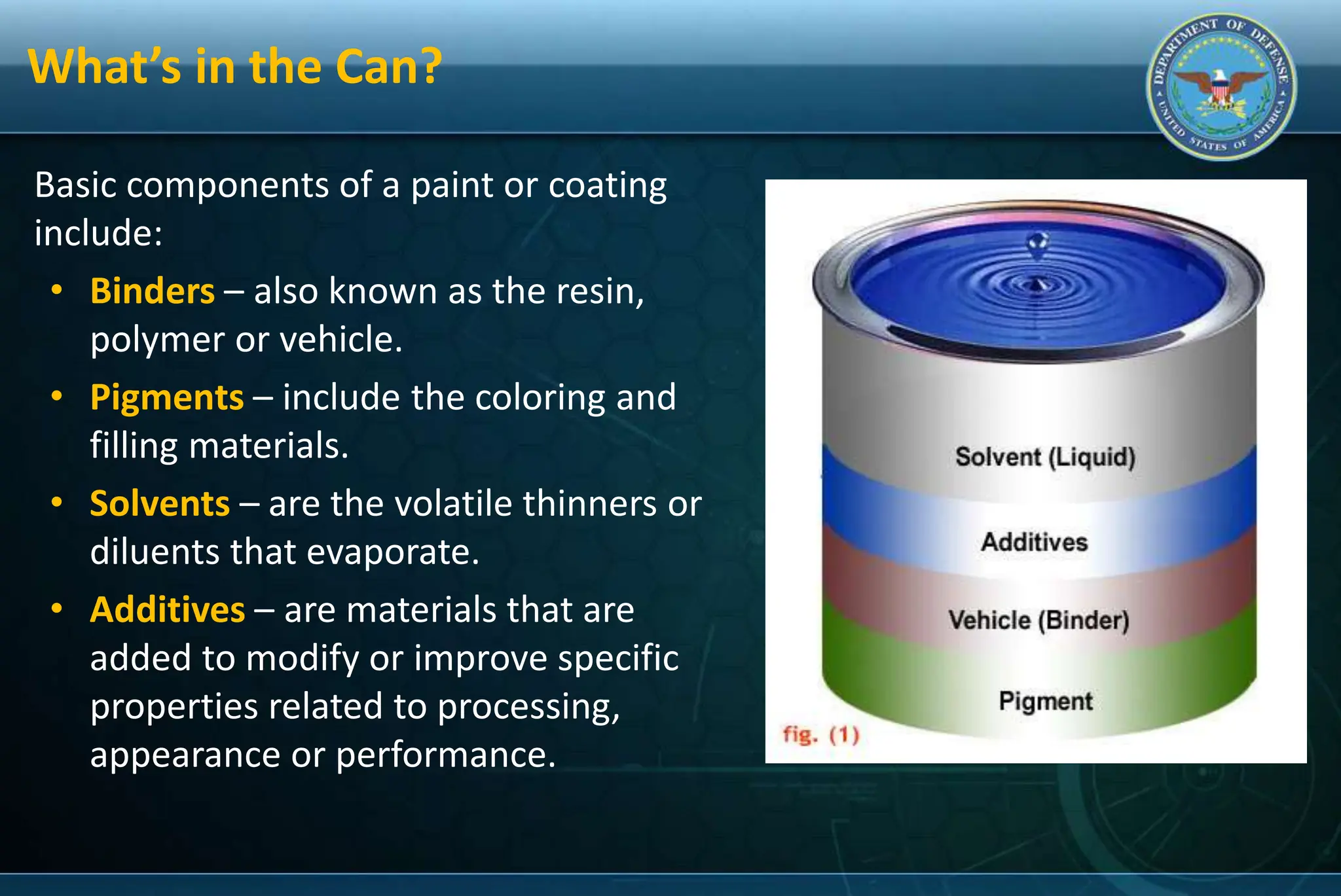

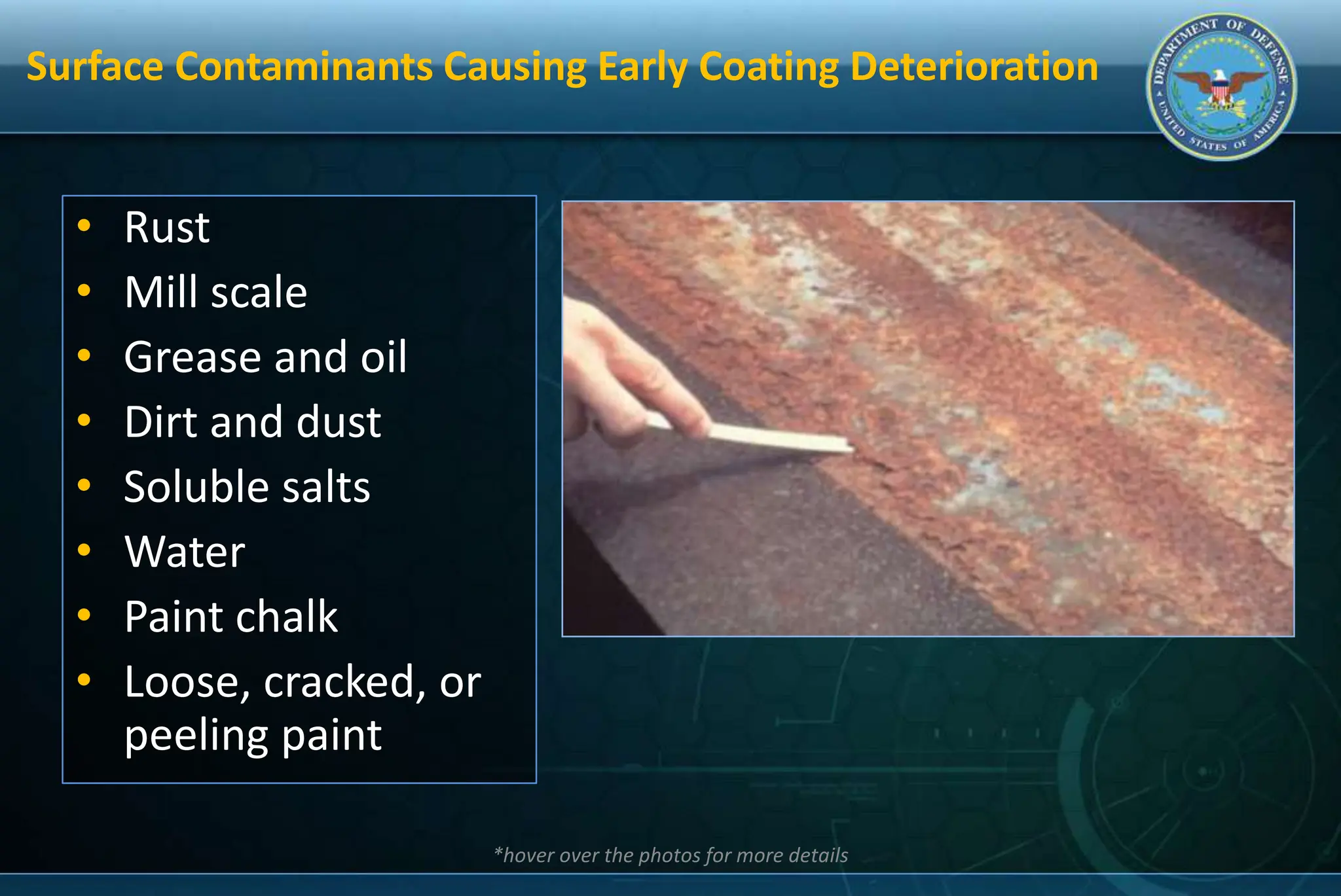

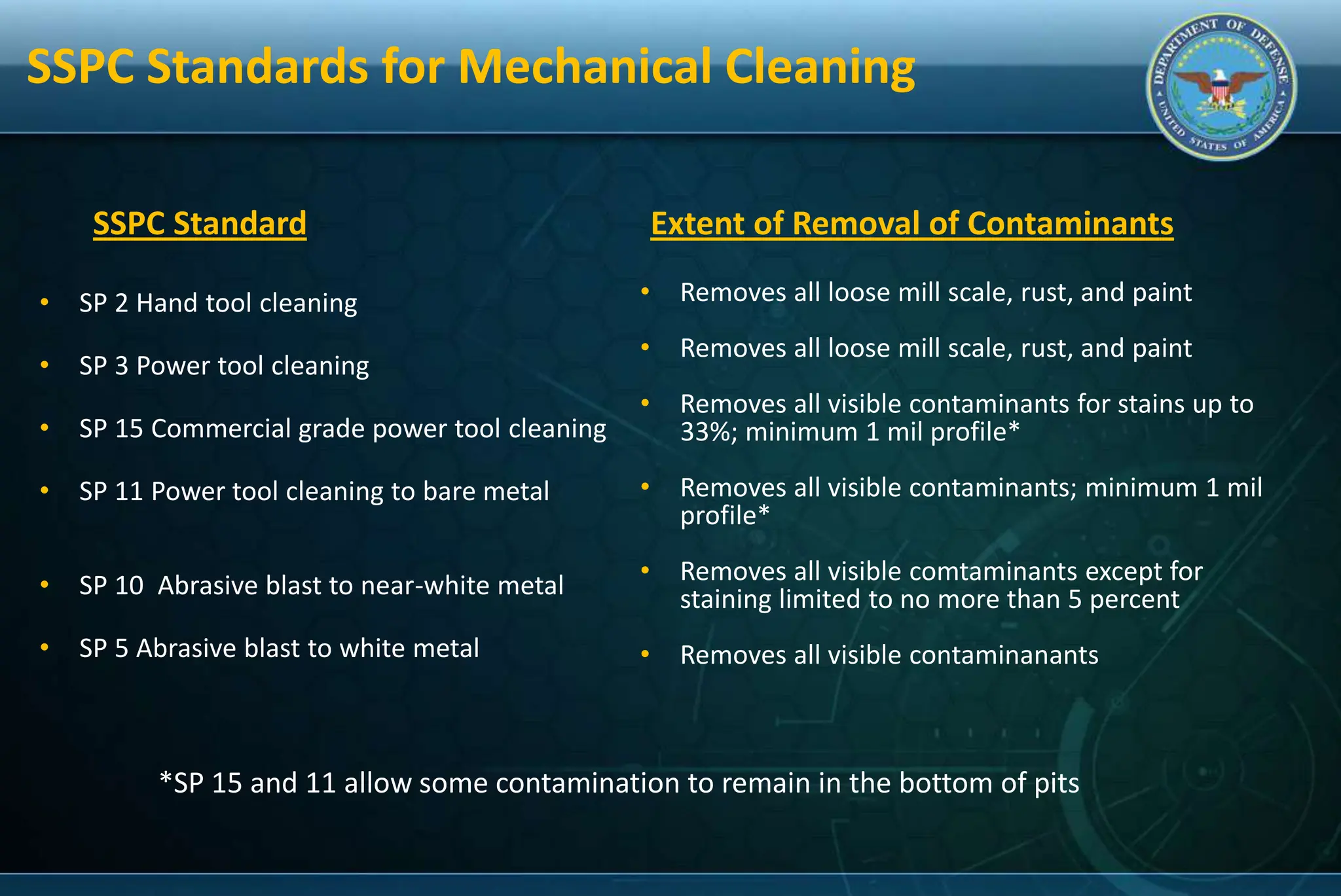

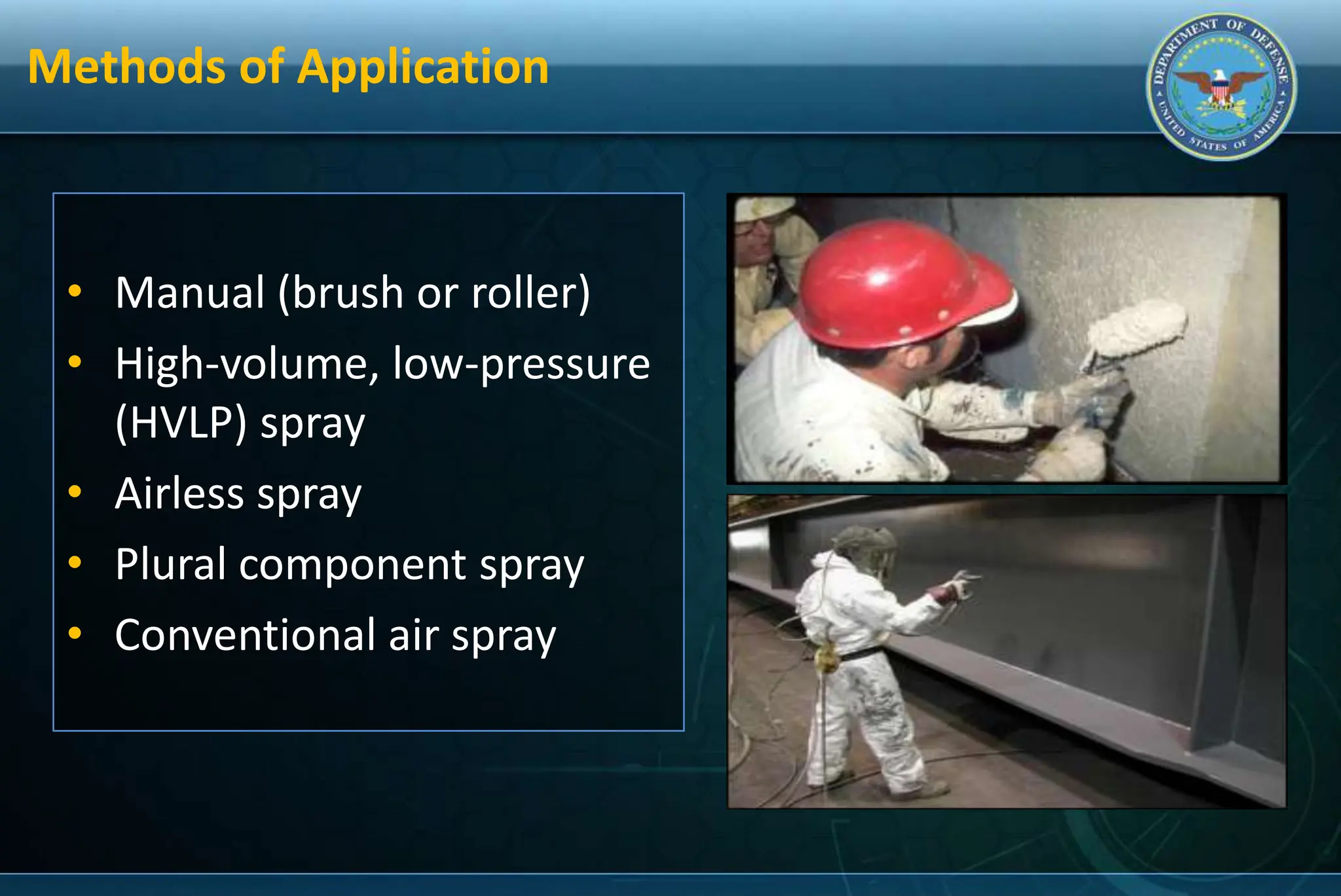

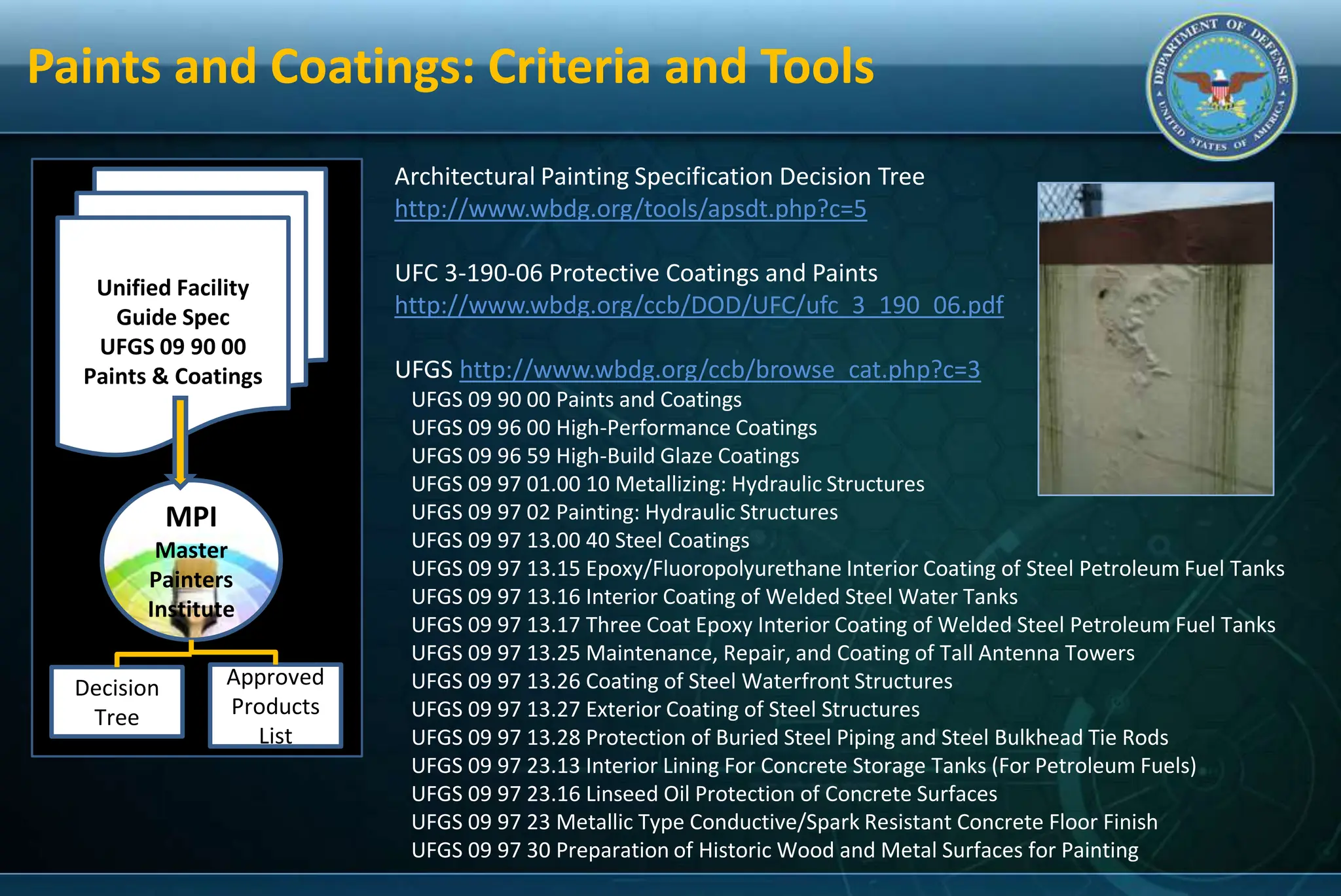

The document provides a comprehensive overview of paints and coatings specifically for the Department of Defense (DoD), covering their applications, classifications, and essential factors in selection and maintenance. It emphasizes the significance of surface preparation, specification criteria, and quality assurance processes to ensure the longevity and effectiveness of coating systems in various environmental conditions. A variety of coating types and standards are noted, along with recommendations for addressing corrosion and maintaining infrastructure.