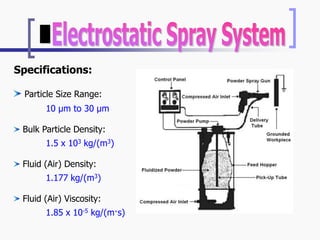

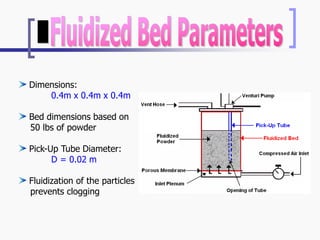

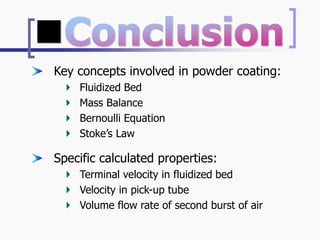

Powder coating is a dry finishing process where paint particles are electrostatically charged and sprayed onto a workpiece. The coated part is then cured in an oven, which causes a chemical reaction bonding the powder to the surface. Key aspects of powder coating include using fine paint particles that are fluidized and sprayed, then cured without solvents. This makes powder coating durable, environmentally friendly and cost efficient compared to wet painting methods.