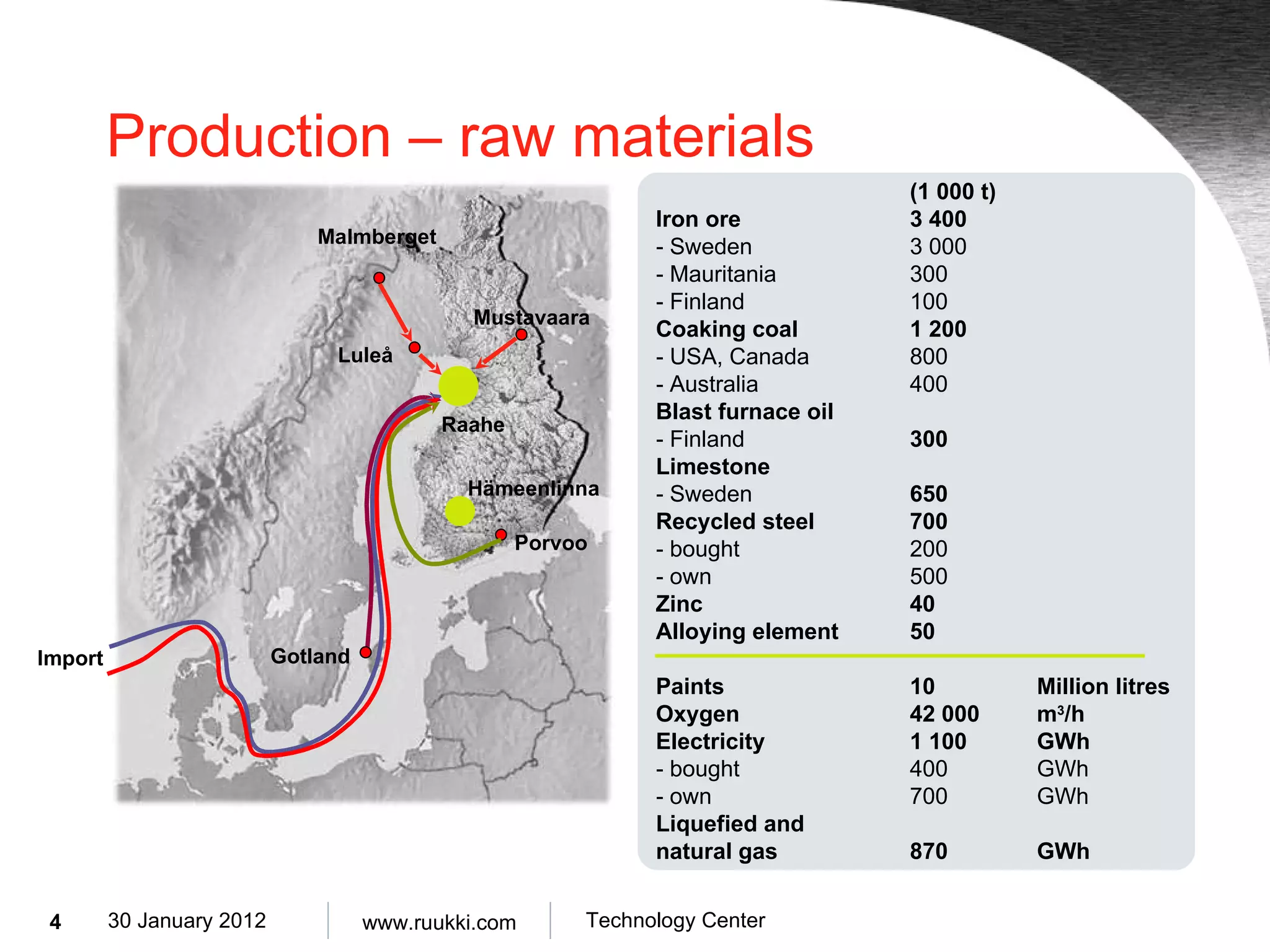

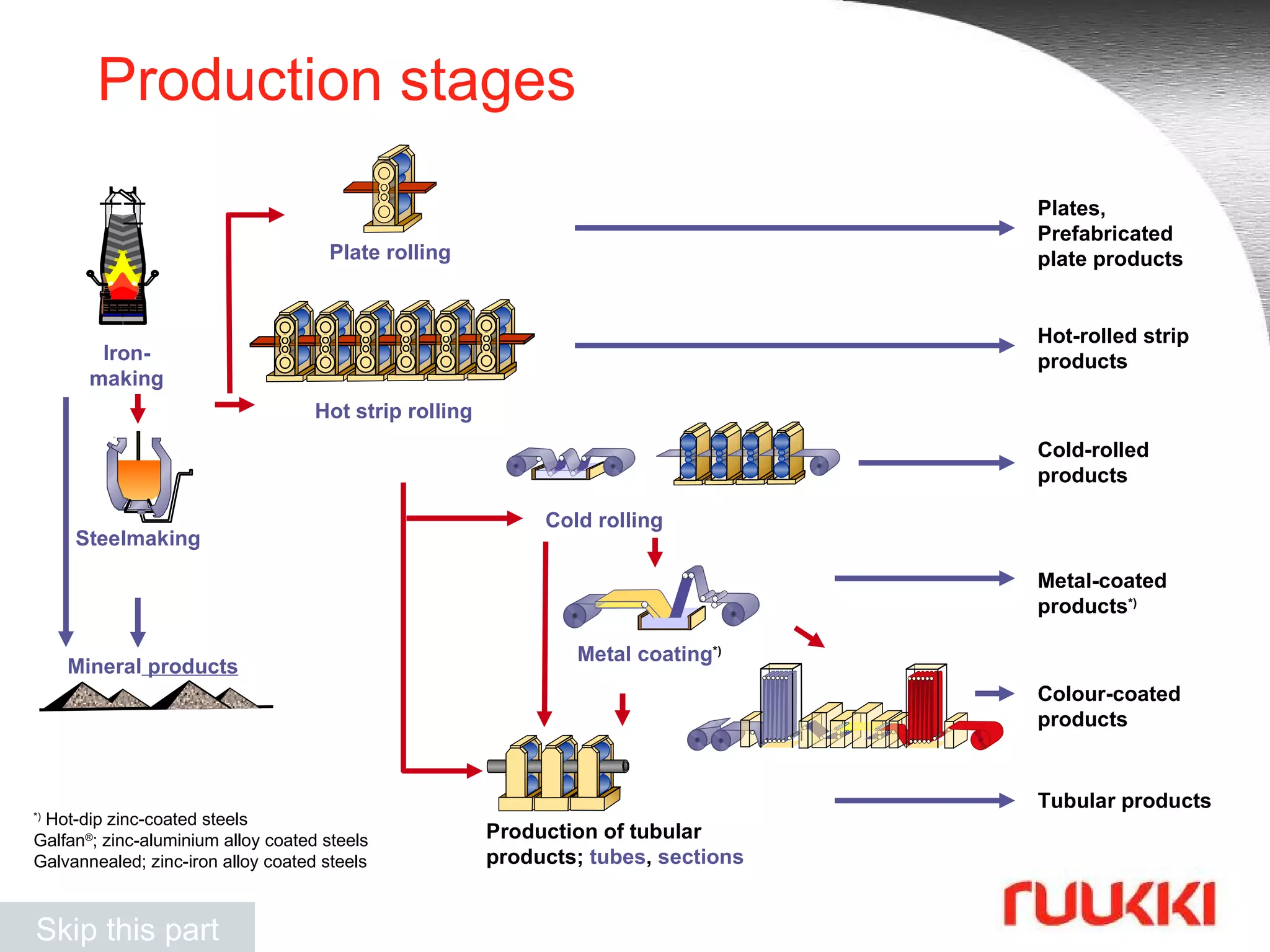

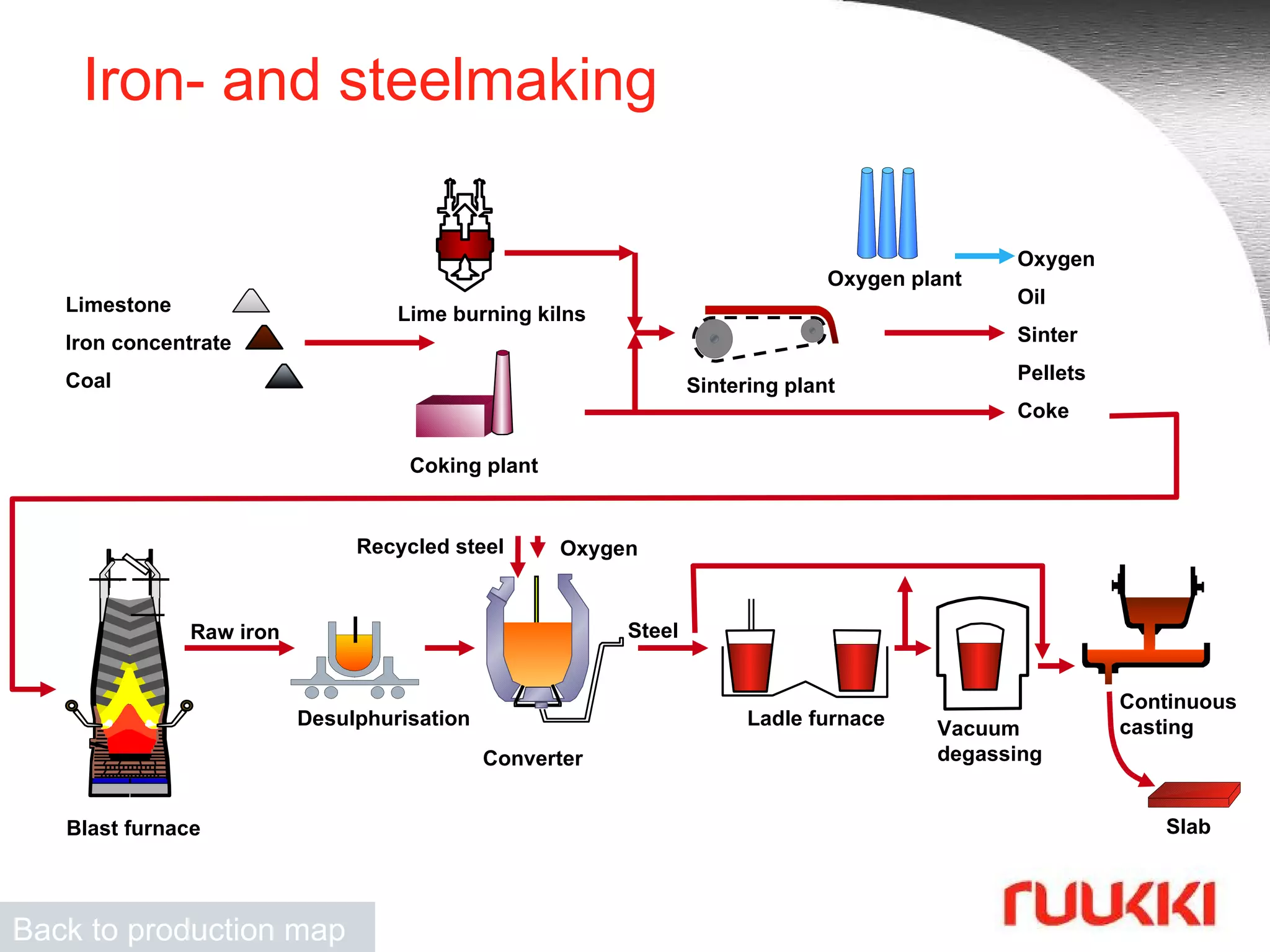

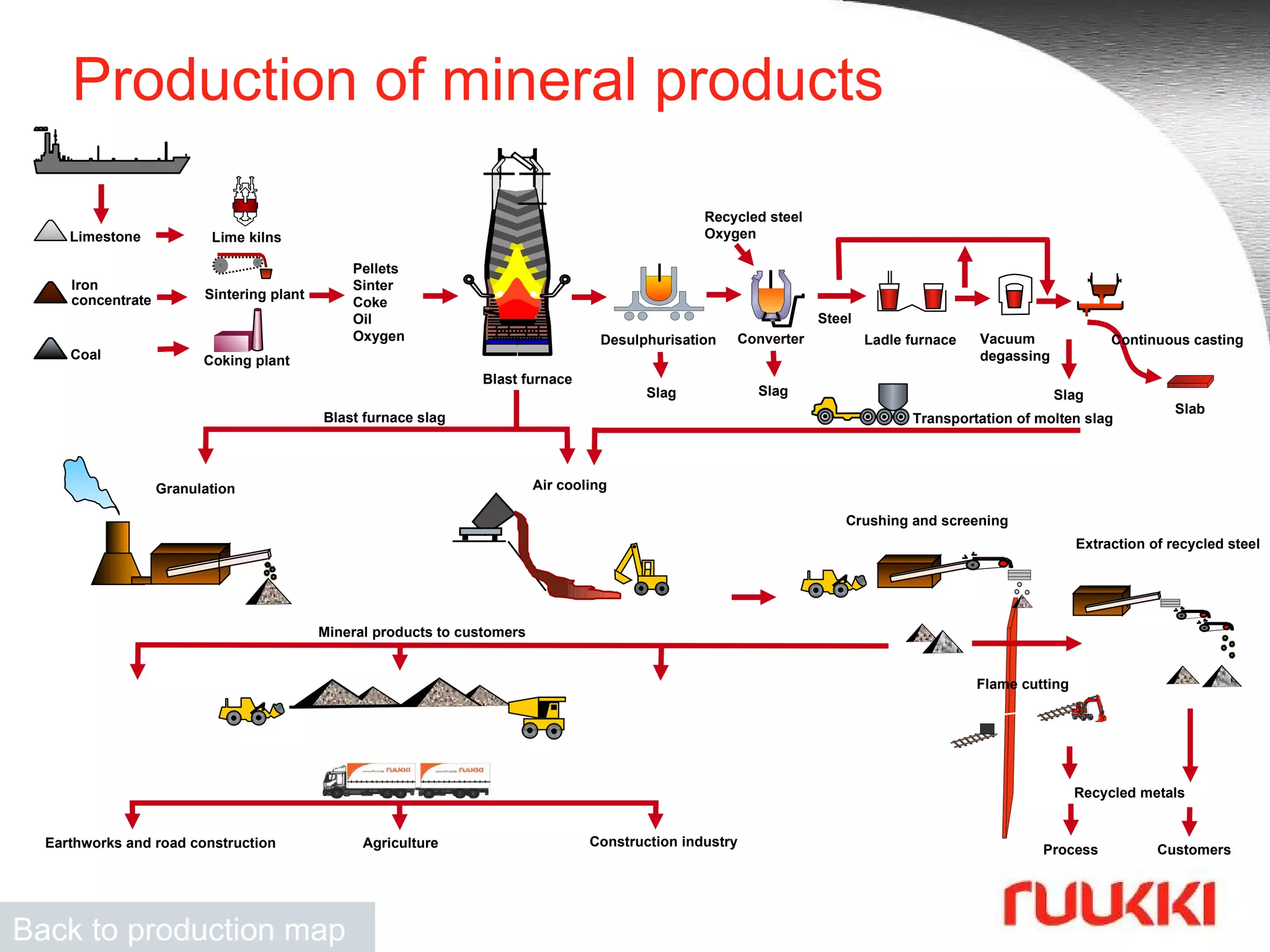

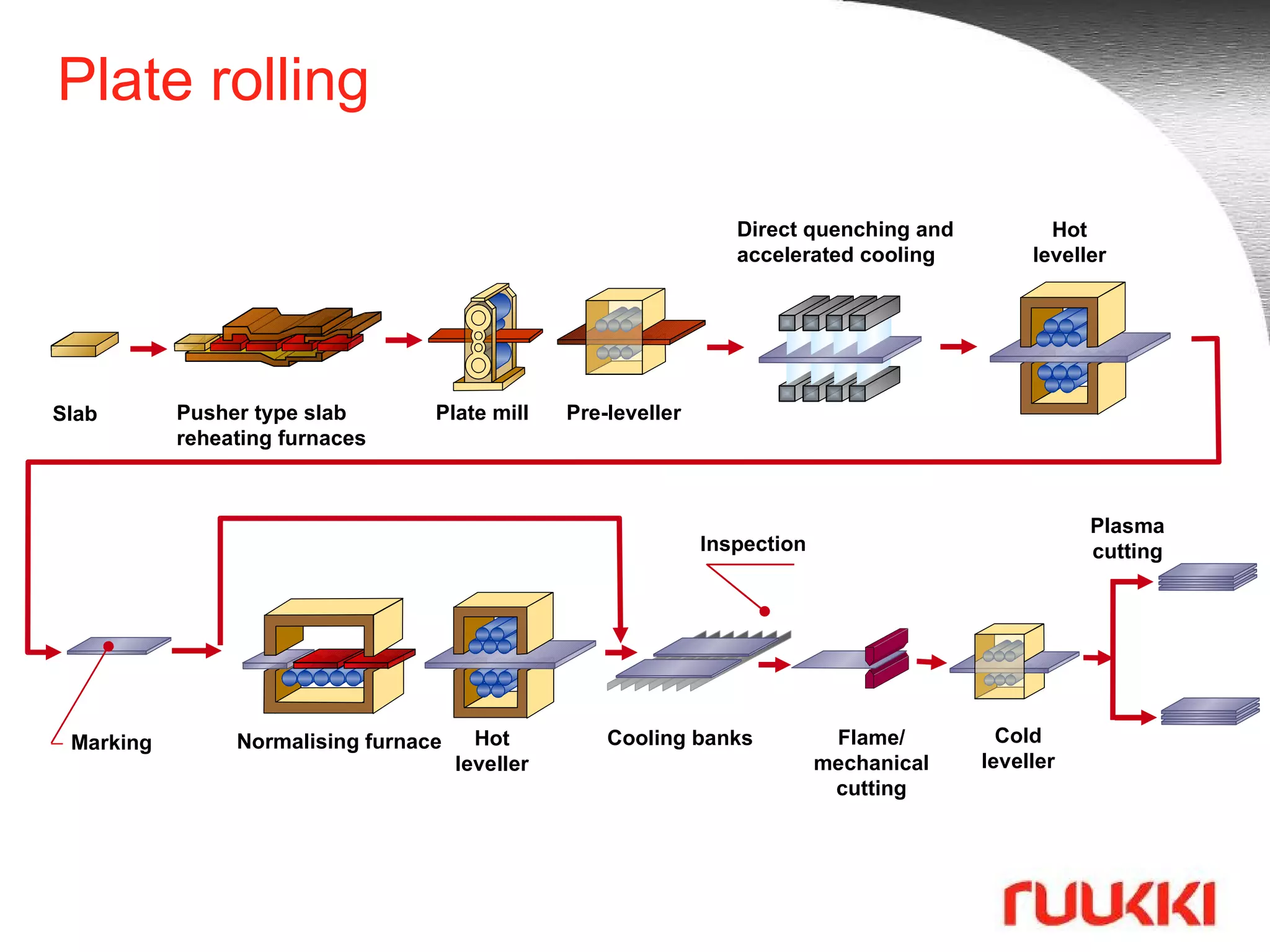

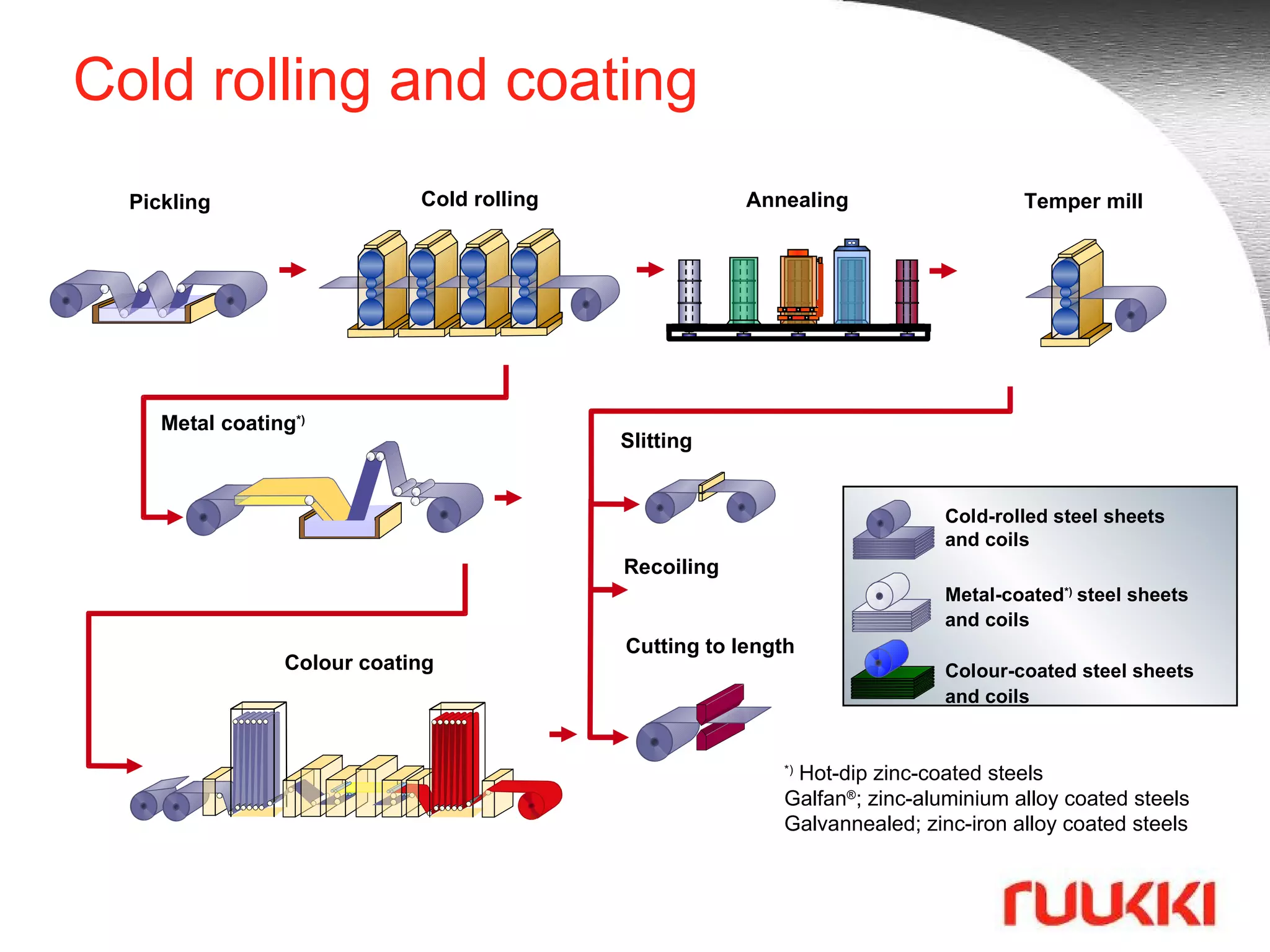

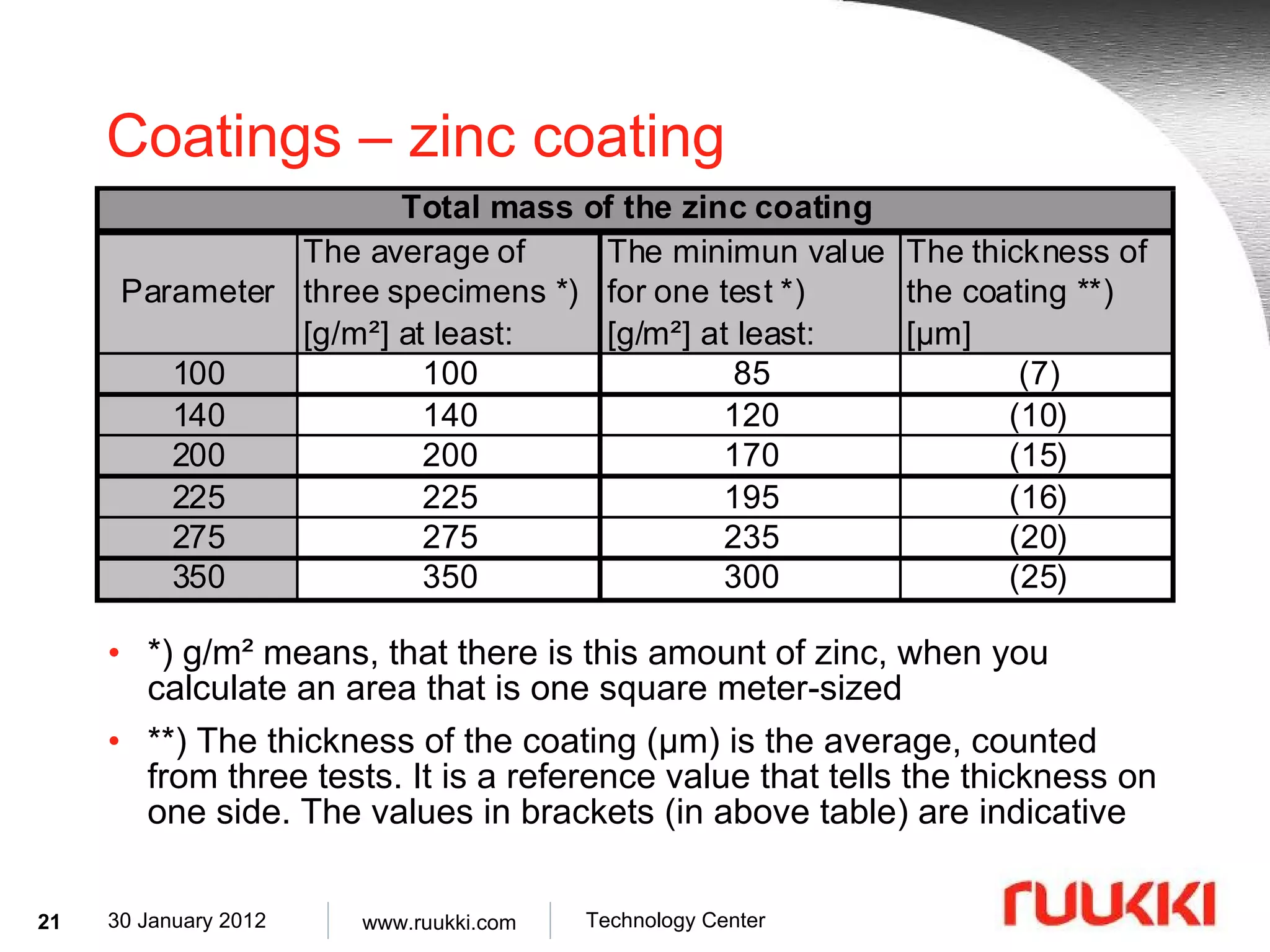

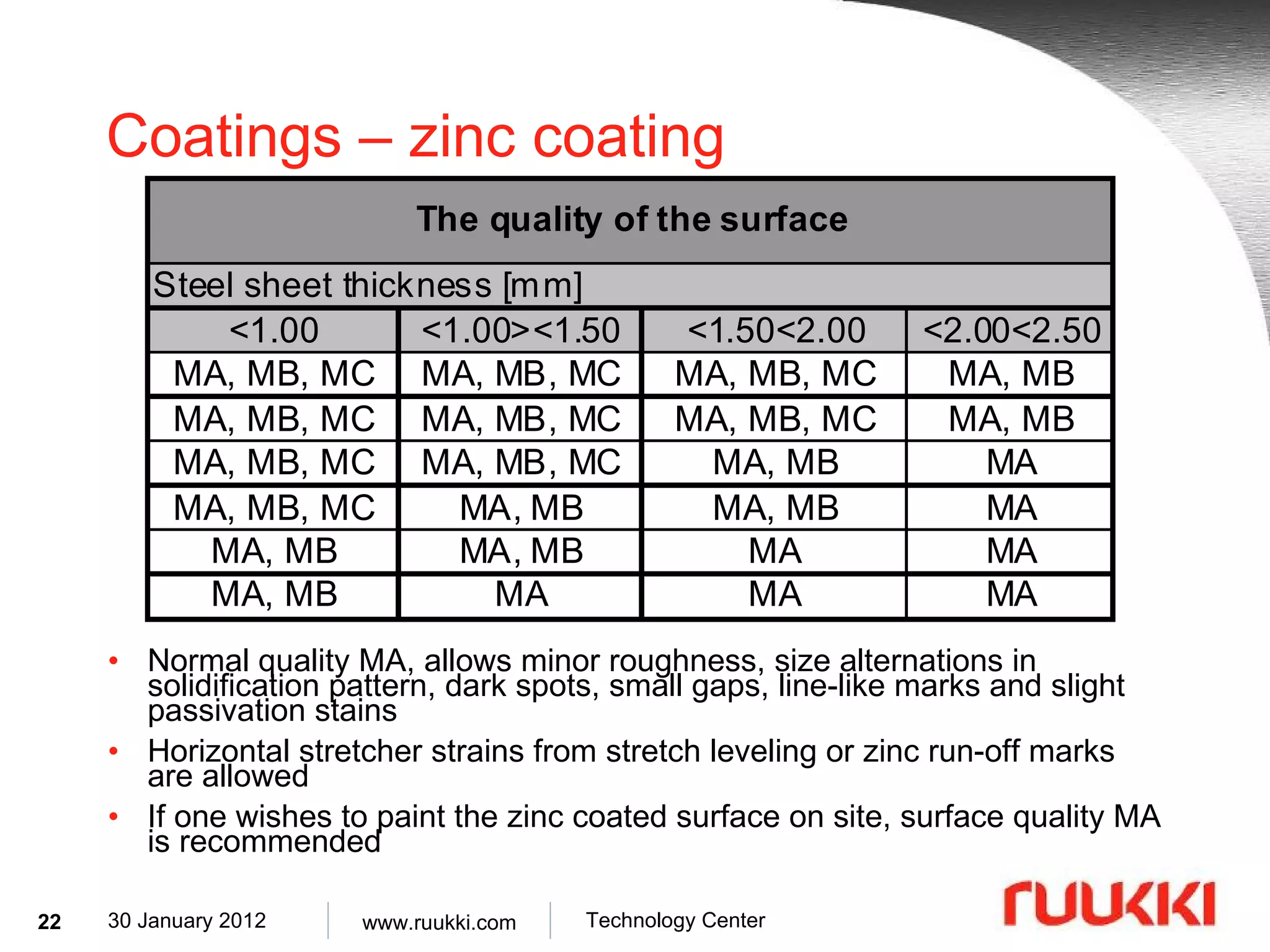

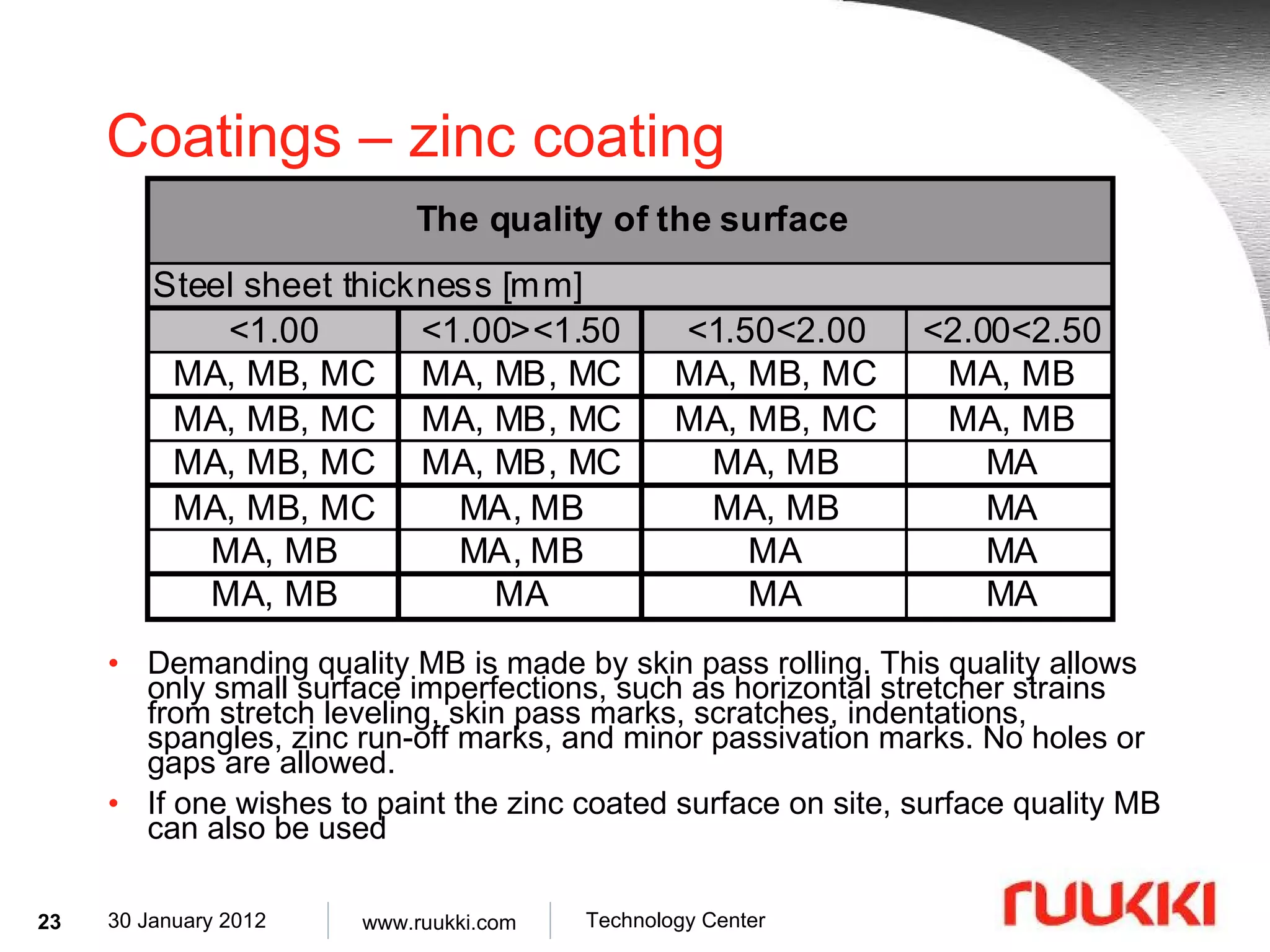

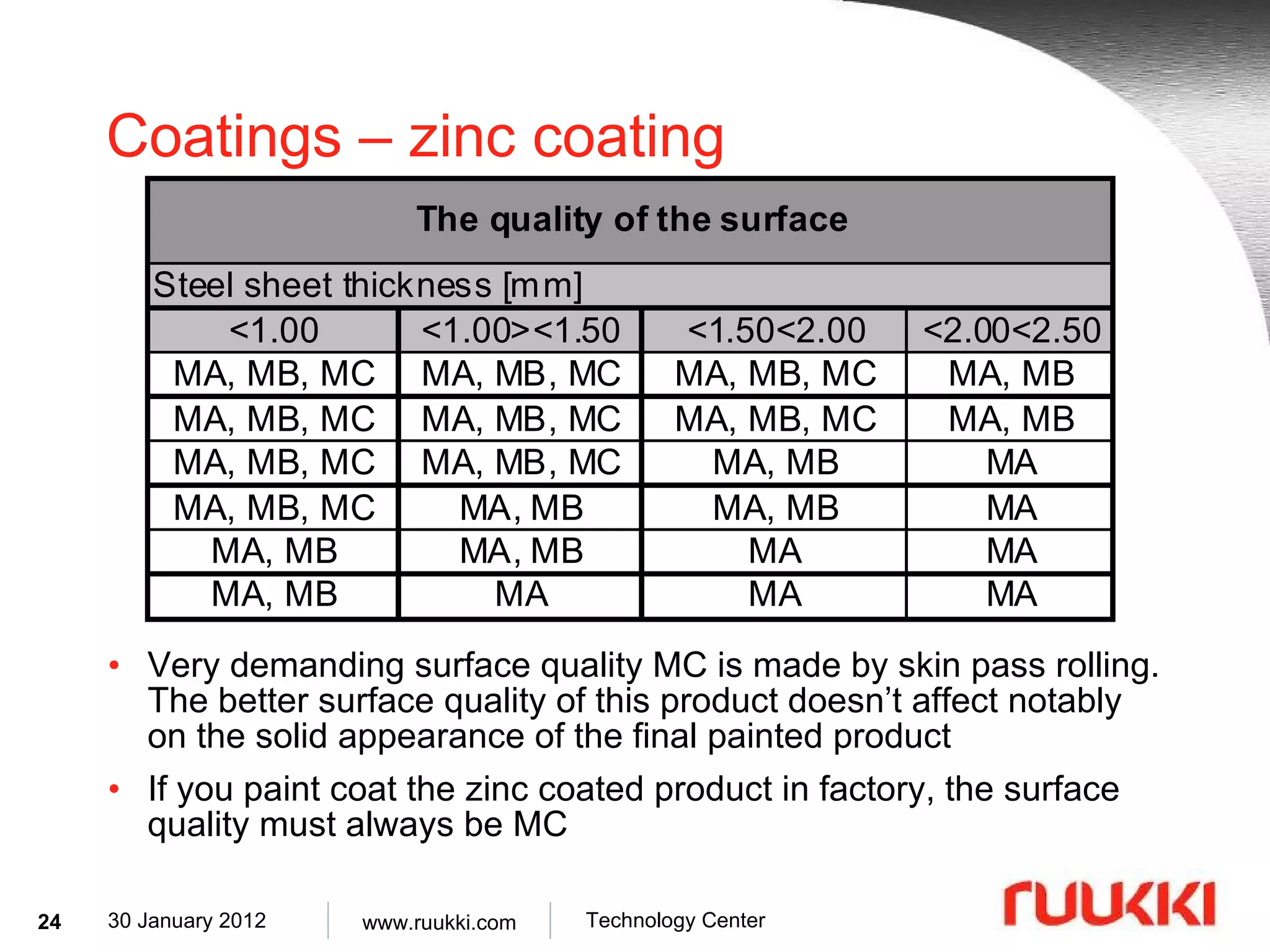

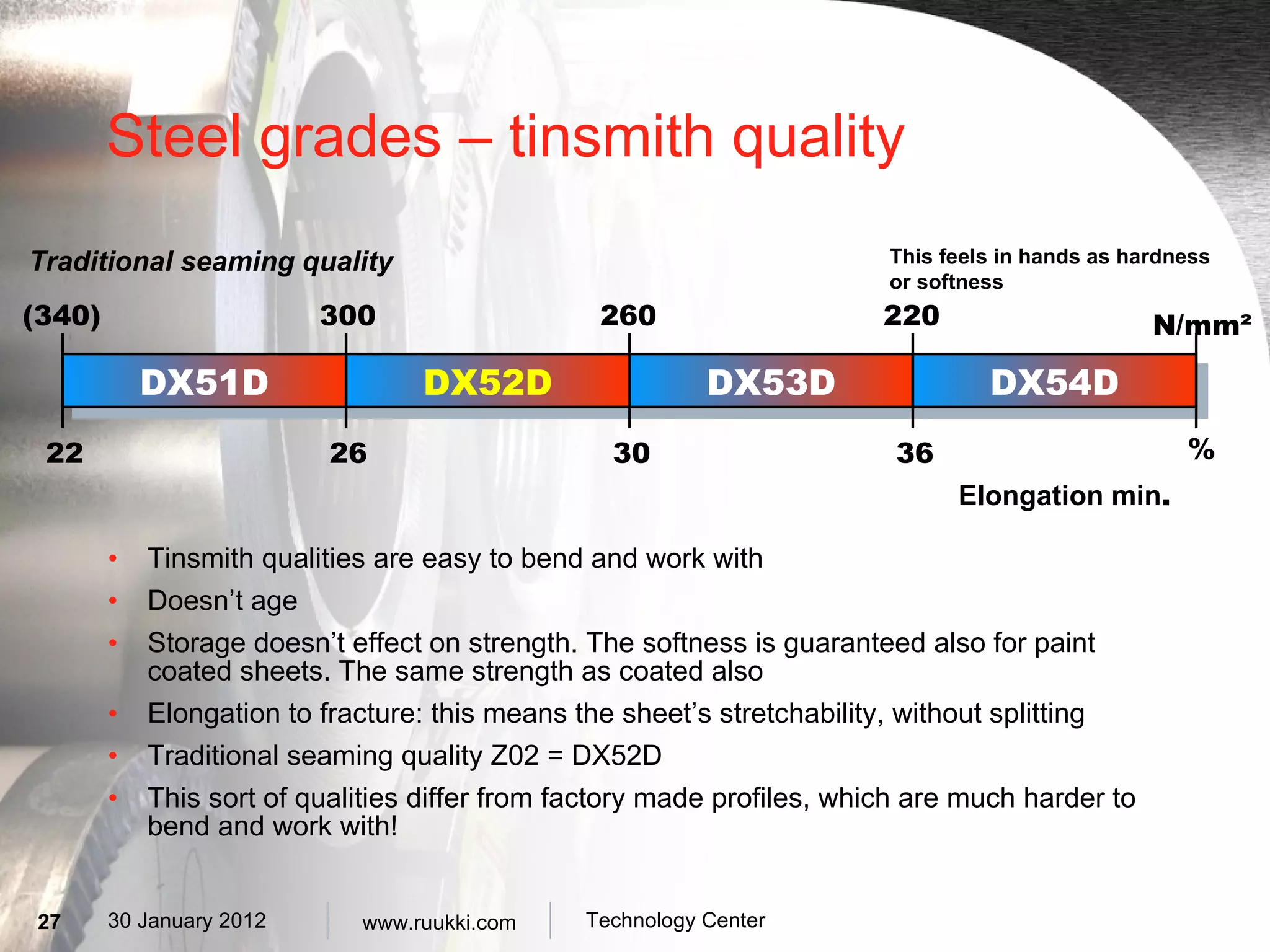

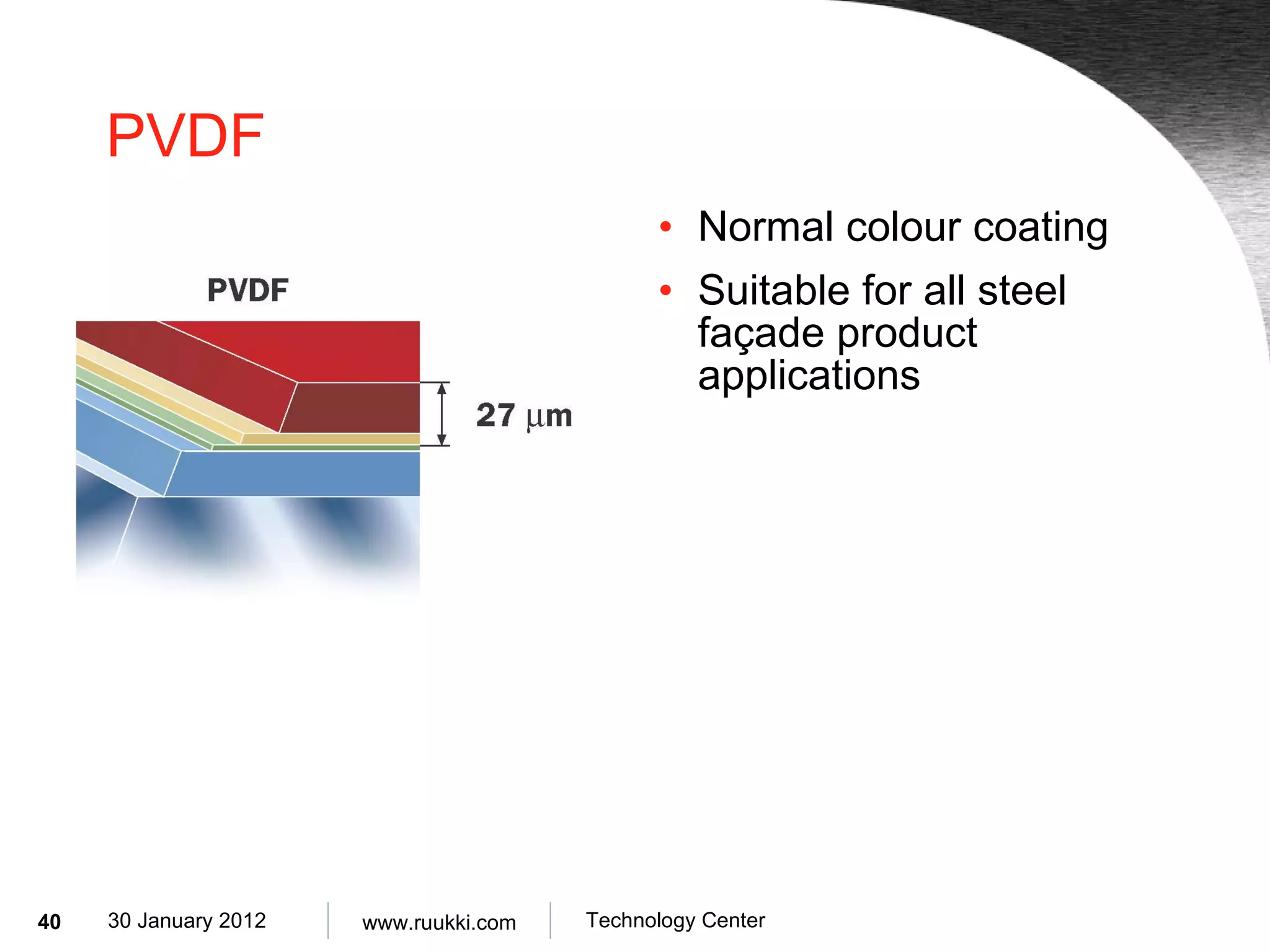

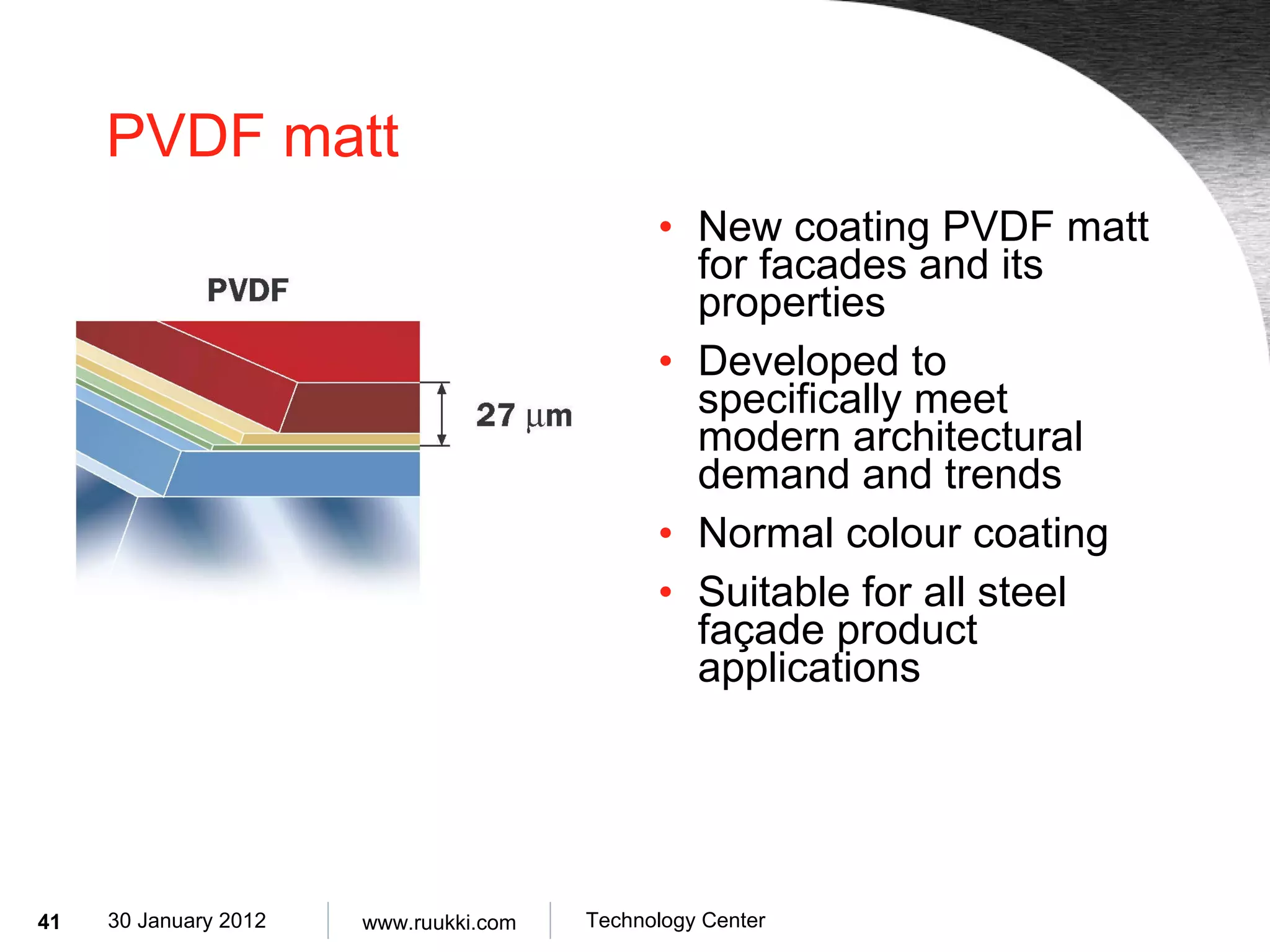

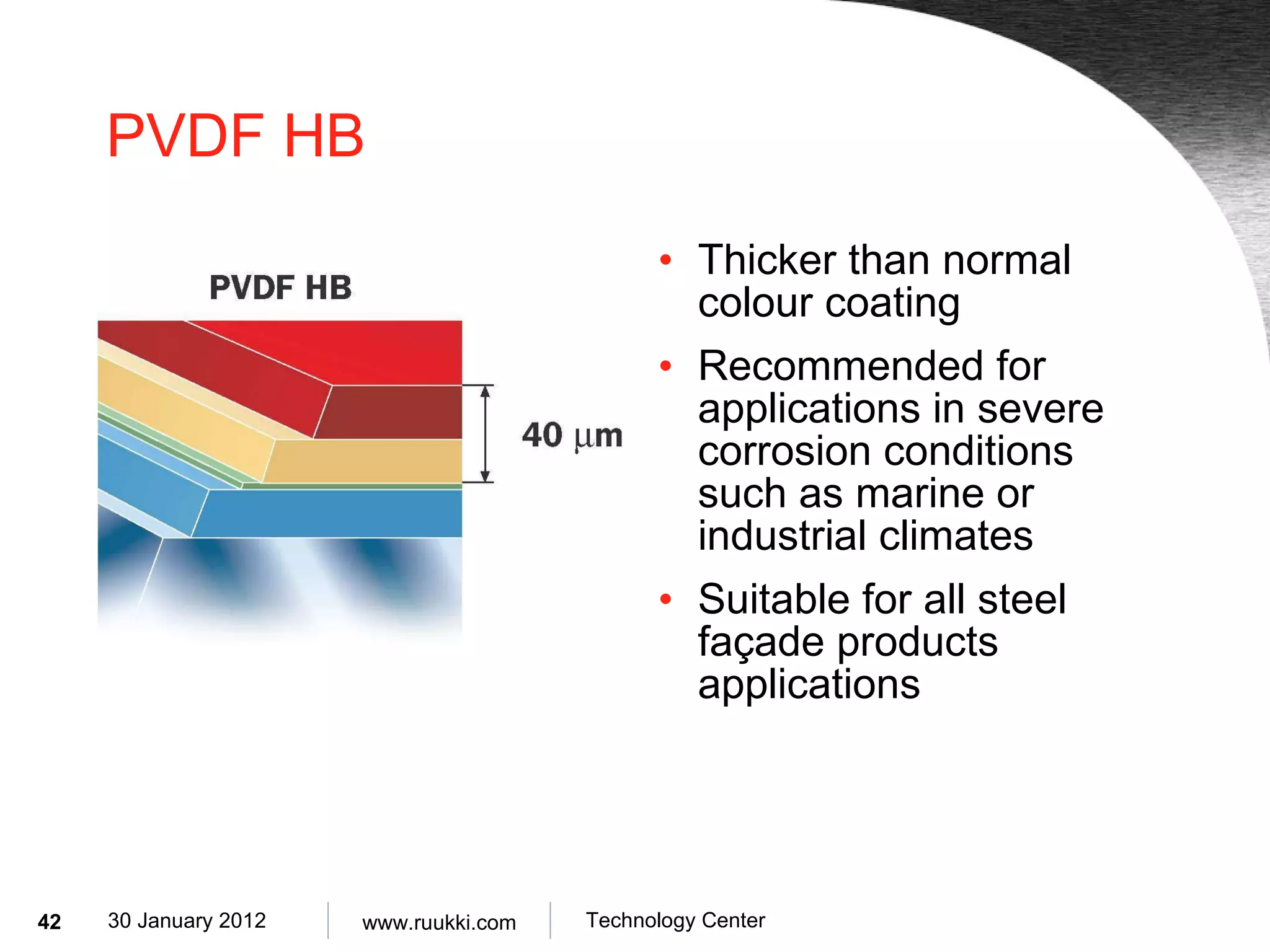

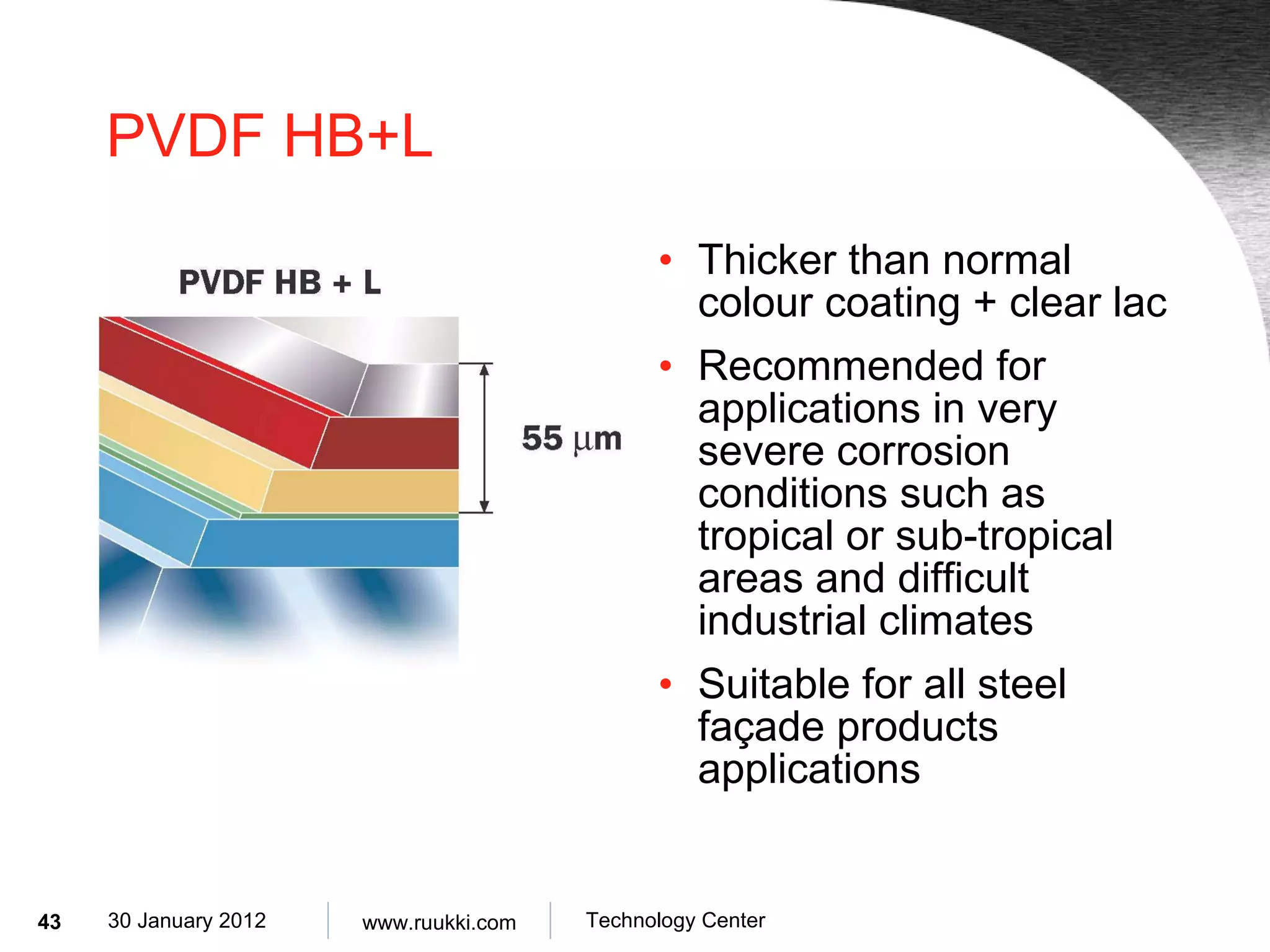

The document outlines the production processes and materials involved in manufacturing coil coated steel, highlighting various coatings such as zinc, Galfan®, and PVC laminate. It details the production stages, including cold rolling, metal coating, and coating options tailored for different applications to ensure quality and performance. Additionally, the document lists steel grades and their specific applications, emphasizing the importance of material properties in various industrial contexts.