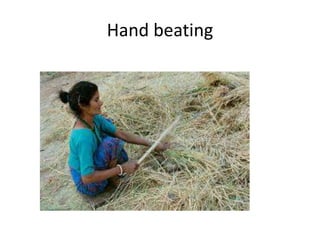

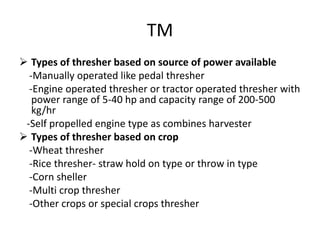

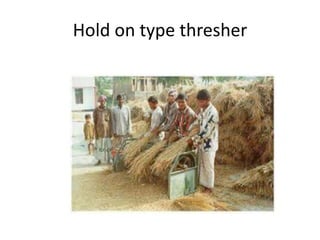

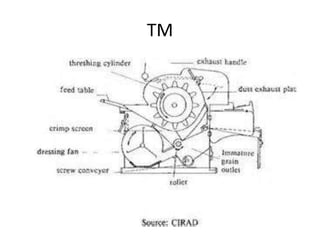

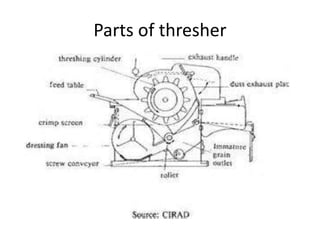

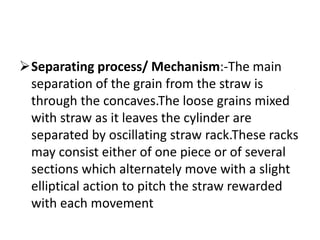

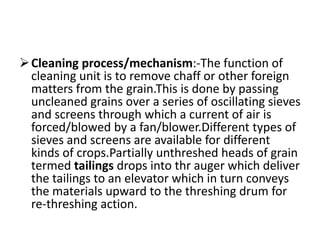

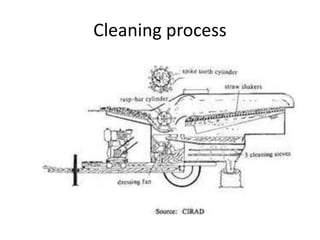

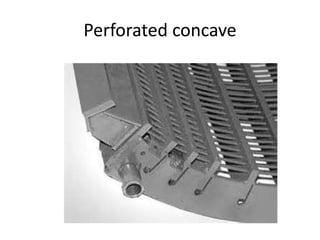

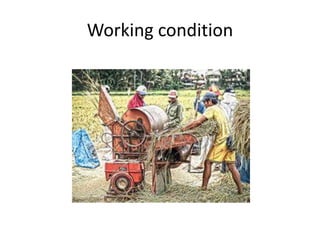

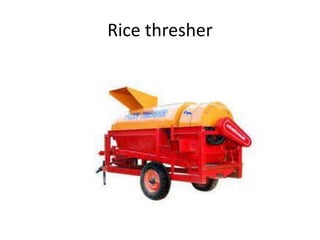

This document discusses threshing machines, including their types, construction, and performance factors, aimed at agricultural engineering students. It covers various threshing methods, mechanization advancements such as combine harvesters, and the operation mechanisms of threshers and maize shellers. The document emphasizes ongoing research to improve machine efficiency and effectiveness in grain separation in different crop contexts.